Budget Battles Bumping Backlogs?

Patrol And Combat Builders Fret About Budget Cuts But See Bright Spots. So far; so good.

U.S. companies building patrol and combat craft aren’t happy about federal, state and city budget cuts but say they do see positive, demand-side factors. Much of their overseas business depends on the U.S. Foreign Military Sales program. The FMS, which transfers defense equipment and services to other nations, is retrenching now, however. Here at home, states and municipalities have fewer funds, grants and matching grants to pay for patrol vessels, builders say. Nonetheless, patrol and combat boats remain in demand because of terrorism, crime and piracy, along with weak maritime defenses in a number of nations.

Bollinger Shipyards: in the thick of the battle

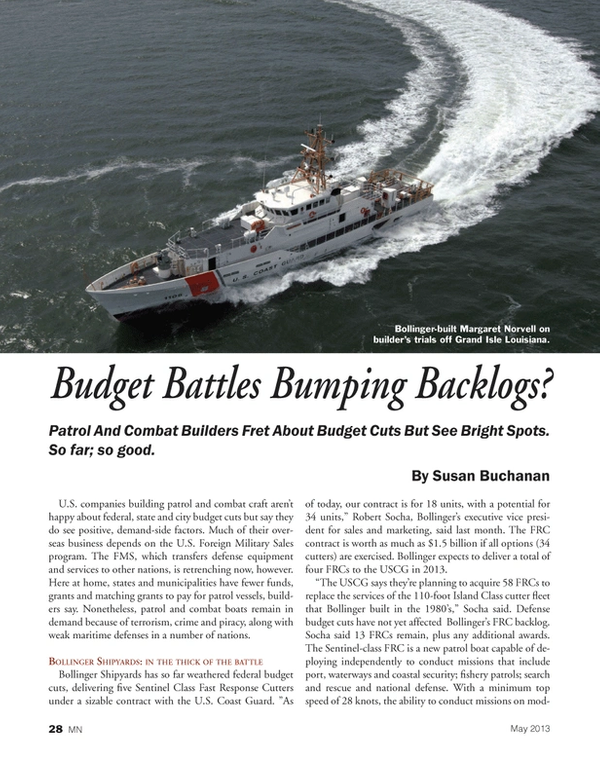

Bollinger Shipyards has so far weathered federal budget cuts, delivering five Sentinel Class Fast Response Cutters under a sizable contract with the U.S. Coast Guard. ”As of today, our contract is for 18 units, with a potential for 34 units,” Robert Socha, Bollinger’s executive vice president for sales and marketing, said last month. The FRC contract is worth as much as $1.5 billion if all options (34 cutters) are exercised. Bollinger expects to deliver a total of four FRCs to the USCG in 2013.

“The USCG says they’re planning to acquire 58 FRCs to replace the services of the 110-foot Island Class cutter fleet that Bollinger built in the 1980’s,” Socha said. Defense budget cuts have not yet affected Bollinger’s FRC backlog. Socha said 13 FRCs remain, plus any additional awards. The Sentinel-class FRC is a new patrol boat capable of deploying independently to conduct missions that include port, waterways and coastal security; fishery patrols; search and rescue and national defense. With a minimum top speed of 28 knots, the ability to conduct missions on moderate seas up to transit speed for eight hours and survival on very rough seas up to loiter speed for eight hours is a critical part of the FRC mission set. Heavily armed, the FRCs measure 154’ LOA, drawing 9’ 6” in draft and have a range of 2,950 nautical miles. They can carry a crew of 24. U.S. Coast Guard Commandant Adm. Robert Papp insists that the Sentinel class is a critical asset, but Papp also said recently that getting all of the National Security Cutters built was one of his top priorities.

Swiftships: Banking on Global Sales

Swiftships Shipbuilders produces military-grade patrol crafts, with 126 commercial hulls produced since 1947, with swift patrol boats and commercial vessels sales in over 40 countries. Although quite busy at the moment, CEO Shehraze Shah also admitted that because of sequestration-induced, federal budget cuts, industry is having a tough time. And, demand from U.S. FMS clients has declined. “The PMS 325 NAVSEA PEO has been affected by furloughs and is too short-staffed now to be effective,” he said. PMS 325 is the Support Ships, Boats and Craft Program Office within the Defense Department’s group called PEO Ships, which procures mission and support vessels.

“Both old and new ship-building programs are being shifted because of budget cuts,” Shah said. “Timelines have been delayed. Swiftships’ last three 35m patrol boats, which were part of an original 15 PBs through a letter of authorization approved by the Iraqi Navy, have been delayed. Pressure by the Iraqi Navy to deliver them isn’t enough to force the USN to move.”

“The impacts of furloughs, budget cuts and volunteer time-offs by Foreign Military Sales within the USN threatens U.S. shipbuilding,” Shah said. Demand for patrol boats is still strong, however, because of ongoing piracy, terrorism and inadequate maritime defense in the Middle East.

Separately, Swiftships’ 28m Coastal Patrol Craft, part of a strategic plan by the Obama Administration, brings aid to Egypt and helps that nation create jobs,” he said. Swiftships has built most of Egypt’s Naval Fleet since 1984 and has supported EN’s 25m Patrol Craft Program, and is now building 28m patrol crafts under a $180 million contract.

Swiftships is the first American shipyard to offer a foreign military partnership – in this case with Egypt under U.S. State Department-approved Camp David funds, Shah said. Under the State Dept.’s “Build, Operate, Transfer” program, Swiftships offered two 28m patrol crafts – PC595 and PC596 – delivered to Egypt in late 2011, along with four PC597-600 hulls as KITS for construction in Egypt. Construction of these vessels is done by the workers in Alexandria, Egypt under the supervision of Swiftships Subject Matter Experts.

Swiftships is under an LOR with the EN for an additional four patrol crafts, Hulls 630 to 633, with the contract expected to be awarded to Swiftships by September 2013. This program allows EN to train its trades craftsmen in Swiftships’ main facility in Morgan City to learn American capabilities and quality, while enforcing a positive alliance between the United States and Egypt, Shah said.

In February, Swiftships delivered two 35-meter patrol boats PB-310 and PB-311 to Iraq, the tenth and eleventh vessels in a $282 million contract. PB-312, the twelfth vessel, left Morgan City in late April and will arrive in Umm Qasr on June 1. Swiftships has benefited from a partnership between the U.S. and the rejuvenated Iraqi maritime defense.

North River: US Navy Harbor Security

North River Boats has delivered the first eight of nine, 36’ U.S. Navy Force Protection Large Harbor Security Patrol Boats under a contract valued at just over $3 million. Mike Blocher, director of sales explained, “We’re scheduled to deliver the ninth boat in early July,” he said.

The Navy harbor security boat FP-L is a high-speed craft designed to protect lives, facilities and equipment, Blocher said. With propulsion is provided by Twin 250 HP Yamaha 4.2L four stroke outboard motors, cruising speed ranges from 27.9 knots to 29.3 knots, based on a full load or a light ship. Maximum speed with a full load is 39.2 knots. Key features include an enclosed cabin; heating and air conditioning; aft deck space for cargo; an overhead canopy for sun protection; a hybrid foam and air fender for hull protection, stability, and flotation if swamped; multiple weapons foundations; adjustable outboard motor crash-rope guards; diver’s recovery ladders; a Furuno Navnet electronics package; FLIR Thermal Imaging; a Gentex intercom, VHF and UHF radios; NVIS compatibility and an emergency lighting package.

The company is also scheduled to deliver several patrol or combat vessels to various federal, state and local agencies: These include valor models ranging up to 36’ in length; Liberty models ranging from 38’ to 40’ in length and multiple Sounder vessels. These boats will be used for law enforcement patrol, fire and rescue and combatant craft.

“We’re preparing for an eventual domestic downturn from U.S. budget cuts,” Blocher said. “We’ve noticed reductions in quantities of boats purchased by government agencies. The time from proposal and bid to award has increased considerably. Additionally, you have continued issues within state and municipal funding,” Blocher added. “Most of what we see is grant funds that are finally being spent. A lot of the grant funds come with stipulations that the state or county has to match funds, which they may not have in their budget. We’ve seen some contracts get pulled or delayed because of lack of funding.“

“Fortunately, we are a very diverse company. We have a steady backlog of various boats, ranging from recreational to commercial and government,” Blocher said. “We have firm orders and a steady workload through the first half of 2014. We have the ability to increase capacity as needed in a new manufacturing facility that we’ll move into by late May.” He adds, “This will be the first time in our company’s history that all production will be under one roof.”

North River will, Blocker said, continue to leverage the firm’s growing market share, while also pursuing other venues of potential business. “We’ve been working on several market areas that we feel will pay dividends for us in the future.”

Metal Shark: Delivering Here, and Abroad

Like others in this unique business, Metal Shark works to diversify its customer base while leveraging its considerable backlog. Greg Lambrecht, vice president of Metal Shark Boats, said “we specialize in patrol and combat vessels and deliver throughout the United States and the world. We’re delivering a variety of vessels to the U.S. mainland, Virgin Islands, Hawaii and Guam for the U.S. Navy, Coast Guard and Air Force, as well as states and local municipalities. These vessels are also being provided to multiple countries in the following regions--PACOM, EUCOM, CENTCOM, SOUTHCOM and AFRICOM. A majority of our vessels have optional propulsion packages--ranging from gasoline outboard, diesel shaft drive, diesel outdrive or diesel jet.”

“Our foreign contracts are a mixture of direct country sales and FMS through the U.S. government,” Lambrecht said. “We currently maintain a healthy backlog, domestically and internationally. While we haven’t seen a decrease in sales, out years may be affected if U.S. sequester and future budget forecasts remain unchanged. We have increased our international efforts and sales force to mitigate these risks.”

Silver Ships Builds For Overseas Under FMS

At the end of last year, Silver Ships, Inc. completed construction under a multiple order for Riverine Patrol Boats, awarded through the Navy’s FMS for delivery to the Philippines. Scott Clanton, special projects director, told MarineNews, “Currently we have in construction 11M center console patrol boats, going to the country of Yemen through FMS, along with an additional 11M’s to the U.S. Air Force,” he said. “These FMS contracts yielded about $6.5 million in sales for Silver Ships and continue to enhance our overseas reach. In 2013, we’re building boats for the U.S. Navy and Air Force, as well as oil-recovery crafts for Saudi Arabia. We have approximately five months of backlog for start of construction. With contracts on hand and our projected sales, it looks as if we’ll be extremely busy this year.”

“Our U.S. government program contracts, being fulfilled at the moment, are Dept. of Defense support crafts,” Clanton said. “Silver Ships continues to execute its state, federal and foreign government programs, and has welcomed the FMS as an extension to our commitment to deliver mission-capable platforms.” He added, “On any given day in the factory here, you’ll find law enforcement boats side by side with U.S. Navy program boats, with a variety of state, federal & DOD and foreign markets mixed in.”

Built for the Navy’s FMS program, the company’s 40’ x 10’8” RPB’s features an enclosed center console, bow area, designed for transporting troops and equipment-- in support of maritime green and brown water patrols and providing rapid egress through the bow door. “This is the first of this type of craft built by Silver Ships,“ Clanton said. “As a manufacturer, our first and foremost concern is that the boat operates safely and as intended and that our servicemen and women can operate and maintain the vessel.”

Clanton added, “Looking at how the dynamics of current military events have pulled resources and redirected them, and considering the funding issues impacting us all, money is tight and probably will be for some time,” Clanton said.

Ocean Craft Produces Agile, Blacked-Out RIBs

At Ocean Craft Marine, the company’s new 9.5 VI-BTD high-performance boats are designed for elite law-enforcement and military mariners. Todd Salus, Ocean Craft vice president, said “we saw unique opportunities to partner with fellow marine industry leaders and to collaborate on constructing a new range of high-performance boats. These boats pair the latest advances in maritime shock-mitigation and communication systems with Ocean Craft’s superior concave-chine hull designs. We introduced our new product range, starting with this unique, high-endurance, 9.5 meter, rigid hull inflatable boat designed for high-speed vessel interdiction and boarding team delivery.”

Because of the competitive nature of its business and often-classified customer activities, Ocean Craft doesn’t release contract specifics on models, customer identities, quantities and contract values.

“The 9.5M VI-BTD, with its blacked-out visual appearance, super-quiet, twin 300HP Mercury Verado supercharged engines, and a shock-mitigated console with a low-profile and oblique-angled leading edge make for an extremely stealthy and agile package on the water,“ Salus said. “With four integrated hoisting hard-points, this boat is ready for shipboard launch and recovery, as well as transportation by rotary wing aircraft.”

Ocean Craft partnered with Professional Components Ltd. in Canada, makers of Shockwave Seats, to customize and adapt a three-axis, fully shock-mitigated operator console known as the Integrated Control Environment, Salus said. In addition, the latest 9900 Series fully integrated, wireless crew-communications system was specially adapted by the David Clark Company in Massachusetts, along with an M-Series thermal imaging camera from FLIR Systems, Inc. in Oregon.

MetalCraft: High-Speed Patrol Boats For USCG

At MetalCraft Marine, sales and marketing representative Laurence Bishop said “our first Long Range Interceptor II or LRI II has been delivered to the U.S. Coast Guard and is currently being evaluated on the Guard’s National Security Cutter. It is the first of four, with the potential for ten overall. We will be delivering two more by the end of the year.” MetalCraft partnered with Brunswick Government and Commercial Products in this LRI II contract. Each LRI II is valued at $840,000.

MetalCraft builds high-speed aluminum patrol, fire and rescue boats and is the designer of the Brunswick Line of Sentry Patrol Boats. The high-speed LRI II patrol boat is 35’long, and is powered by twin Cummins Tier III 6.7L diesels and Ultra 305 waterjets with electronic joystick controls, and can reach 42 knots. Engines are JP-5, or alternative bio-fuel optional, and have a 5-minute run-dry feature. All systems are designed for equatorial and arctic conditions. The LRI II has a range of 236 nautical miles. It can carry fifteen crew or passengers in ergonomic suspension seating. The cabin can be fully enclosed and has 360-degree visibility. The vessel is outfitted with a closed cell-foam fendering system that can withstand nine knots of impact.

Bishop said “our second build for the USCG is a 44’ Response Boat, with the first of two to be completed by the end of June.” Those vessels will head to Tunisia. Each 44’ response boat costs $860,000 each. As for government budget cuts, Bishop said “we have yet to experience exactly how sequestering will affect our orders.”

Port Police Need Patrol Craft, too

All American Marine recently delivered a 65’ patrol and dive boat to the Los Angeles Port Police,” Joe Hudspeth, vice president of business development told MarineNews that the 65’ hydrofoil-assisted patrol catamaran is valued at $2.5 million. “Our current contracts are from the private sector,” he said. “But our current backlog contains orders for passenger vessels and we’ve been talking to potential customers about new patrol vessels. So we remain optimistic.”

Willard Marine Sends RIBs Overseas, too

Also involved with foreign markets, Willard Marine, Inc. in Anaheim, Ca. plans to deliver a series of vessels under the FMS Navy program through 2013, including 7-meter Rigid Inflatable Boats, 9-meter RIBs and 11-meter RIBs to the Philippines, Lebanon and Ukraine. Boats for the Philippines are already in country and Willard has sent training personnel there. Vessels will be delivered to Lebanon early this summer and to Ukraine in the fourth quarter, according to C.J. Lozano, Willard’s director of government products. The company is also chasing direct sales with other countries. Willard has a backlog through 2014.

Outlook: Diversity is Key to Longevity

Since government budgets are unlikely to fatten up anytime soon, diversity is the best way to stay afloat in the current climate, combat and patrol boat manufacturers said last month. And there are a raft of builders involved. Hedging bets by catering to a combination of government and private customers – both domestic and overseas – with a varied product line will be the ticket to survival in an iffy market. In the nation’s boatyards, the dance between what is possible, affordable and what is absolutely required; continues. In the meantime, big backlogs keep builders busy – for now.

(As published in the May 2013 edition of Marine News - www.marinelink.com)

Read Budget Battles Bumping Backlogs? in Pdf, Flash or Html5 edition of May 2013 Marine News

Other stories from May 2013 issue

Content

- By the Numbers: Subchapter M Statistics page: 8

- Subchapter M Looms Operators and Suppliers Respond page: 10

- Insights: Rear Admiral Joseph A. Servidio page: 12

- Managing Jones Act Personal Injury Litigation page: 18

- Class NK’s subM Strategy: Help is on the Way page: 22

- Budget Battles Bumping Backlogs? page: 28

- Unique Propulsion for Unique Workboat Applications page: 36

- Honda’s Flagship BF250 Engine page: 42

- Pumps and Piping: A Curious Turn to the Right page: 46