Bringing Workboats “Into the Cloud”

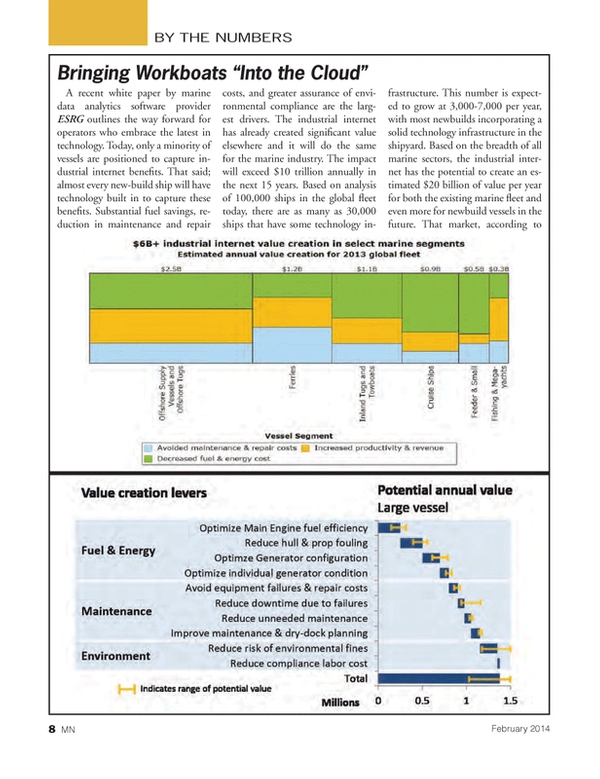

A recent white paper by marine data analytics software provider ESRG outlines the way forward for operators who embrace the latest in technology. Today, only a minority of vessels are positioned to capture industrial internet benefits. That said; almost every new-build ship will have technology built in to capture these benefits. Substantial fuel savings, reduction in maintenance and repair costs, and greater assurance of environmental compliance are the largest drivers. The industrial internet has already created significant value elsewhere and it will do the same for the marine industry. The impact will exceed $10 trillion annually in the next 15 years. Based on analysis of 100,000 ships in the global fleet today, there are as many as 30,000 ships that have some technology infrastructure. This number is expected to grow at 3,000-7,000 per year, with most newbuilds incorporating a solid technology infrastructure in the shipyard. Based on the breadth of all marine sectors, the industrial internet has the potential to create an estimated $20 billion of value per year for both the existing marine fleet and even more for newbuild vessels in the future. That market, according to ESRG, could exceed one billion dollars in the next five years. Potential annual value creation for individual ships could be as high as $1 million.

Newer ships launched recently are equipped with more sensors, providing more and more performance and condition data that can be used to operate and maintain equipment at a higher performance levels and at a lower cost. A new vessel today might have over 1,000 data points, which would create 2.6 billion pieces of data over a month. When extrapolated across a fleet of 100 assets, this equals more than 3 trillion data points per year. And, the ways that the Internet can benefit your bottom line are almost endless:

Condition Based Maintenance (CBM): The reduction of maintenance costs as well as energy consumption will be more easily through better technology. By doing the right maintenance, at the right time, at the right cost, surprises could be avoided during extended maintenance periods.

Condition Based Operations (CBO): Operators use real-time data and analytics to make better operational decisions to optimize the operation of the asset.

Fuel and Energy: The marine industry brings together the complexity of both power generation assets and energy consumption assets. A ship has to focus on both the energy production and consumption sides of the equation. This underscores the value that collecting operational and condition data in real-time and automatically analyzing can have above what an onboard operator can do with simple spreadsheets.

Environment: From inland tugboats to offshore platforms, the more efficient use of the Internet will also decrease the risks associated with non-compliance with environmental regulations. The transportation sector accounts for 13% of global greenhouse gas emissions. Marine is a significant driver. This has led to various international, national and local organizations to impose stricter regulations on the types of fuel being consumed and resulting emissions. In addition to emissions regulations, the commercial shipping industry is coming under increasing scrutiny with regards to how ballast water is exchanged or treated to prevent the introduction of invasive species. Lastly, the industry continues to operate with regulations around discharges, including oily waste. All systems can be monitored and automatically analyzed to ensure compliance and transparency for a wide variety of stakeholders.

Smart Equipment and Data Integration: Military vessels have taken the first step in data integration with the US Navy’s LCS (Littoral Combat Ship) having the diesel generators, diesel engines, gas turbines, reduction gears, combining gears, lube oil, shaft bearings, water jets, air conditioning plants and water desalinization plants integrated, with data and analytics available onboard and onshore.

Communications Bandwidth: Ship-owners continue to upgrade their ship-to-shore communications as the cost of satellite communications decrease to less than $1 per megabyte of data. As utilization of existing satellite networks increases, ESRG says that the per-unit cost will also decrease over time. Analytics can be used to validate and qualify the data to ensure that the right data is selected and (economically) transmitted ashore.

Custom Applications: These include “Tow configuration optimization for tugs.” By utilizing actual performance data from engine performance, power, speed through water and tow diagrams, operators will be able to better understand what causes a specific configuration of barges to be more efficient than others. This information can be leveraged to optimize profit, through reducing fuel consumption or reducing time to detach and add barges.

(As published in the February 2014 edition of Marine News - www.marinelink.com)

Read Bringing Workboats “Into the Cloud” in Pdf, Flash or Html5 edition of February 2014 Marine News

Other stories from February 2014 issue

Content

- From the Editor's Desk page: 6

- Bringing Workboats “Into the Cloud” page: 8

- Insights: Outgoing Transportation Sec. Connaughton page: 12

- The Pitfalls of Post Incident Paperwork page: 18

- Mariner’s Medical Certificates – the New Normal page: 22

- Coast Guard’s Proposed Maritime Preemption Assessment Framework page: 25

- Is Your Crew Really Prepared? page: 29

- On Patrol with the U.S. Coast Guard page: 32

- Texas Boats Combat Drug Cartels on the Rio Grande page: 38

- Can Fracking Waste be Carried on the Water? page: 41

- Regulatory Rant – Vessel General Permit page: 44

- HamiltonJet HT900s for World’s Biggest High Speed Crew Boat page: 46

- Borgøy: the World’s first LNG-Fueled Tug page: 48