Rope & Wires: At the Forefront of Technology

The Teufelberger Group’s global reach, research and development and 220 years of combined experience is helping to change the way the maritime industry looks at ‘rope.’

It hasn’t been too long since industry icon Tom Crowley, Jr. offered that the one technology that had the biggest impact on the safety and efficiency of [his company’s] maritime operations was, in a word: ROPE. The reasoning was simple. Today’s lighter, stronger synthetic strands have gone a long way in helping to reduce back and other related lifting injuries on deck. He stands by that answer today. So does Teufelberger, especially when it comes to the innovative products that they bring to the waterfront today.

Established as a premium cordage manufacturer more than 220 years ago, Teufelberger produces products across its three distinct business divisions at its six locations around the globe. The Teufelberger Group’s more than 850 employees specialize in collaborating with numerous business partners to find the product solutions across a broad array of markets and applications.

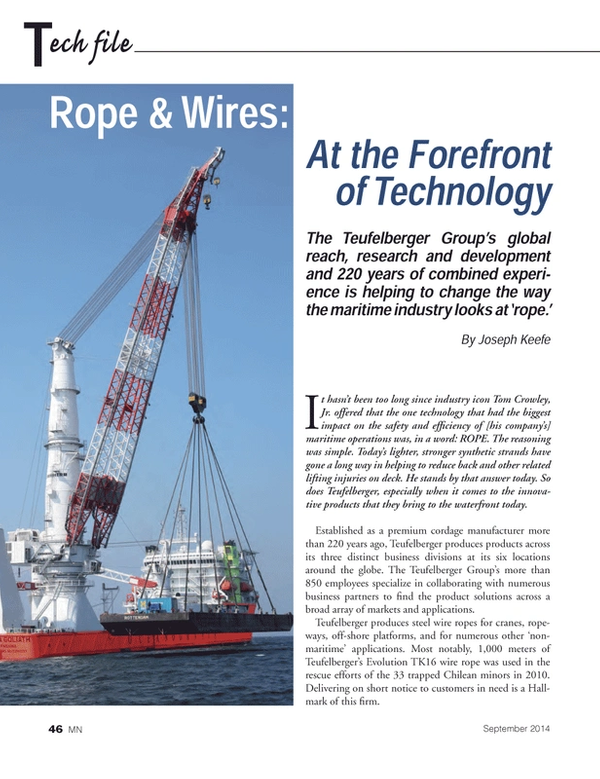

Teufelberger produces steel wire ropes for cranes, ropeways, off-shore platforms, and for numerous other ‘non-maritime’ applications. Most notably, 1,000 meters of Teufelberger’s Evolution TK16 wire rope was used in the rescue efforts of the 33 trapped Chilean minors in 2010. Delivering on short notice to customers in need is a Hallmark of this firm.

Always at the forefront of technology, Teufelberger’s STRESSLESS DATA fiber optics technology facilitates the simple and well protected flow of data across aerial cableways and aerial passenger ropeways throughout the life of the rope. Likewise, and although Teufelberger is generally recognized throughout the world as a manufacturer of wire rope, the company’s fiber rope division also produces rope using the highest quality raw materials, through innovative design and engineering. Teufelberger’s fiber ropes are used in a multitude of applications including: marine for commercial and recreational vessels, industrial and utility, and fall protection. Specifically, Teufelberger Fiber Rope Corporation, the US Division of the Teufelberger Group, is at the forefront of fiber rope technology vastly expanding its operational capabilities in recent years to include the production of large diameter 12-strand lines known throughout the industry as Endura 12. These lines are comprised of 100% Dyneema fiber and are used across all of Teufelberger’s markets in some capacity in numerous very diverse applications. For example, these lines are present on towboats, barges, and help scientists to explore our ocean’s floors.

Endura 12 is exceptionally strong, extremely low stretch, lightweight, and very durable, representing the ideal wire rope replacement because it requires much less manpower due to the fact that it is so lightweight. It does not corrode or rust, results in less injuries, such as cuts on hands and contusions, and does not sacrifice one bit of the strength that steel wire rope provides. The Commercial Marine product line is specifically engineered to provide the strength, abrasion resistance, and elongation characteristics necessary for the majority of Commercial Marine operations.

One of the Teufelberger Group’s latest fiber rope innovations was the development of their brand new STS stronger than steel technology. STS stronger than steel ropes are all manufactured in the United States and are made of Dyneema fiber that is heat-treated under tension at temperatures exceeding 212 degrees Fahrenheit. At a microscopic level, this process causes the molecular chains of the fiber to be oriented in the same direction to ensure that the rope’s load is both evenly balanced and has the ability to bear more weight. Overall, the heat-set process greatly increases the rope’s overall strength and virtually eliminates constructional elongation. An additional user benefit includes the ability to use a smaller diameter line that yields the same or greater amount of strength than a larger non-heat-set line of the same fiber type. Workboat operators no doubt will find this attribute extremely useful.

Teufelberger’s quality standards are reinforced through their adherence to ISO 9001 standards.

According to Teufelberger, whatever your need, they have a line for it. Operating with a philosophy of partnering with customers to find innovative solutions to real world problems, Teufelbeger’s lines are tested and trusted by countless industry professionals and their global manufacturing and engineering capabilities make it easy to provide comprehensive product solutions to customers – on time and on budget. www.Teufelberger.com

(As published in the September 2014 edition of Marine News - http://magazines.marinelink.com/Magazines/MaritimeNews)

Read Rope & Wires: At the Forefront of Technology in Pdf, Flash or Html5 edition of September 2014 Marine News

Other stories from September 2014 issue

Content

- Insights: New York Canal Director Brian Stratton page: 12

- Safety: It's All About Culture page: 18

- In Support of Affordable Energy page: 20

- Business, Bankruptcy, Bad Debt – and You page: 22

- Skip, Skip, Skip to the Loot page: 26

- The No-Emissions Workboat (Really!) page: 28

- Specialty Workboat Missions Propelled by Innovative Engines page: 34

- Moose Boats’ Fire Rescue Catamaran page: 40

- Rope & Wires: At the Forefront of Technology page: 46

- HydraWrap: Not Just a Temporary Repair Anymore page: 48