Page 44: of Marine News Magazine (January 2016)

Read this page in Pdf, Flash or Html5 edition of January 2016 Marine News Magazine

INTERIOR OUTFITTING

WATER &

AIR

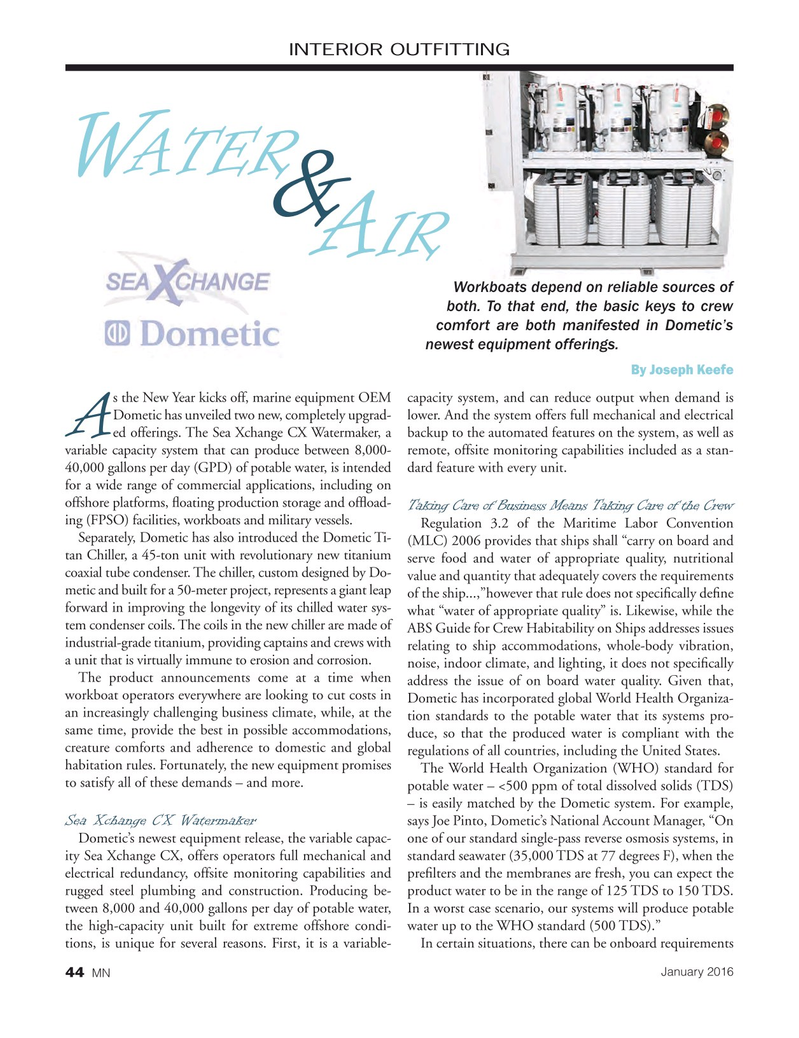

Workboats depend on reliable sources of both. To that end, the basic keys to crew comfort are both manifested in Dometic’s newest equipment offerings.

By Joseph Keefe s the New Year kicks off, marine equipment OEM capacity system, and can reduce output when demand is

Dometic has unveiled two new, completely upgrad- lower. And the system offers full mechanical and electrical ed offerings. The Sea Xchange CX Watermaker, a backup to the automated features on the system, as well as

A variable capacity system that can produce between 8,000- remote, offsite monitoring capabilities included as a stan- 40,000 gallons per day (GPD) of potable water, is intended dard feature with every unit.

for a wide range of commercial applications, including on offshore platforms, ? oating production storage and of? oad-

Taking Care of Business Means Taking Care of the Crew ing (FPSO) facilities, workboats and military vessels.

Regulation 3.2 of the Maritime Labor Convention

Separately, Dometic has also introduced the Dometic Ti- (MLC) 2006 provides that ships shall “carry on board and tan Chiller, a 45-ton unit with revolutionary new titanium serve food and water of appropriate quality, nutritional coaxial tube condenser. The chiller, custom designed by Do- value and quantity that adequately covers the requirements metic and built for a 50-meter project, represents a giant leap of the ship...,”however that rule does not speci? cally de? ne forward in improving the longevity of its chilled water sys- what “water of appropriate quality” is. Likewise, while the tem condenser coils. The coils in the new chiller are made of ABS Guide for Crew Habitability on Ships addresses issues industrial-grade titanium, providing captains and crews with relating to ship accommodations, whole-body vibration, a unit that is virtually immune to erosion and corrosion.

noise, indoor climate, and lighting, it does not speci? cally

The product announcements come at a time when address the issue of on board water quality. Given that, workboat operators everywhere are looking to cut costs in Dometic has incorporated global World Health Organiza- an increasingly challenging business climate, while, at the tion standards to the potable water that its systems pro- same time, provide the best in possible accommodations, duce, so that the produced water is compliant with the creature comforts and adherence to domestic and global regulations of all countries, including the United States. habitation rules. Fortunately, the new equipment promises

The World Health Organization (WHO) standard for to satisfy all of these demands – and more. potable water – <500 ppm of total dissolved solids (TDS) – is easily matched by the Dometic system. For example, says Joe Pinto, Dometic’s National Account Manager, “On

Sea Xchange CX Watermaker

Dometic’s newest equipment release, the variable capac- one of our standard single-pass reverse osmosis systems, in ity Sea Xchange CX, offers operators full mechanical and standard seawater (35,000 TDS at 77 degrees F), when the electrical redundancy, offsite monitoring capabilities and pre? lters and the membranes are fresh, you can expect the rugged steel plumbing and construction. Producing be- product water to be in the range of 125 TDS to 150 TDS. tween 8,000 and 40,000 gallons per day of potable water, In a worst case scenario, our systems will produce potable the high-capacity unit built for extreme offshore condi- water up to the WHO standard (500 TDS).” tions, is unique for several reasons. First, it is a variable- In certain situations, there can be onboard requirements

January 2016

MN 44

MN Jan16 Layout 32-49.indd 44 1/6/2016 2:40:18 PM

43

43

45

45