Page 95: of Marine News Magazine (November 2016)

Workboat Annual

Read this page in Pdf, Flash or Html5 edition of November 2016 Marine News Magazine

LUBRICANTS

Measure Twice; Cut Once

How Testing Helps in Evaluating Environmentally

Acceptable Lubricants (EALs) for Marine Applications.

By Ben Bryant, Marine Market Manager, Klüber Lubrication ithout a doubt, standardized test data for EALs In a recent application in vessels with bow thrusters, an provides the marine industry with a reliable operator used the following criteria to assess EALs:

W basis for evaluating how EALs will perform • OEM approval (indicator of elastomer compliance in operation. Comparing the ? lm thickness of EALs and and wear protection) mineral oil shows important similarities and differences in • Viscosity Index (ability to maintain viscosity over how they separate moving parts at start up and under load. the operating temperature range)

That’s why the road to compliance and performance, ulti- • Dry TOST measure for oxidative stability (indicator mately starts with rigorous testing. of long lubricant life) • Iodine number (indicator of whether the oil is

Assessing Performance fully saturated. Fully saturated esters resist

OEMs and operators typically assess lubricant perfor- oxidation and hydrolysis better than non-fully mance by simply comparing product speci? cations, by di- saturated esters.) rect experience with the product or by references from other users. Following the implementation of the Vessel General

Another operator recently added to the OEM approval

Permit in December of 2013, environmentally acceptable by employing a test for water separability to indicate how lubricants (EALs) were introduced to the market place. With effectively water can be ? ltered out of the oil and thus little historical reference on performance, OEMs and opera- maintain the lubricant’s original performance characteris- tors can look to standardized lubrication tests to understand tics. Klüber also focuses on two additional performance the potential differences between traditional mineral oils and areas relevant to stern tube and thruster applications: shear

EALs, in addition to differences between EALs themselves. stability and ? uid ? lm formation.

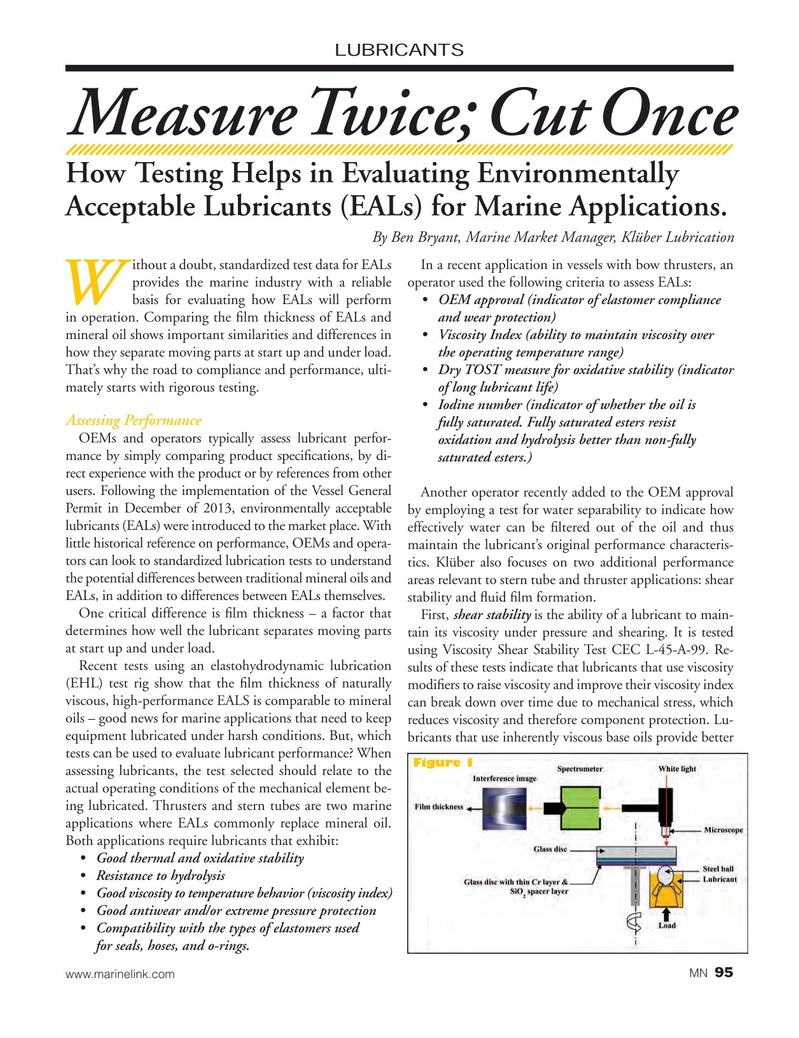

One critical difference is ? lm thickness – a factor that

First, shear stability is the ability of a lubricant to main- determines how well the lubricant separates moving parts tain its viscosity under pressure and shearing. It is tested at start up and under load.

using Viscosity Shear Stability Test CEC L-45-A-99. Re-

Recent tests using an elastohydrodynamic lubrication sults of these tests indicate that lubricants that use viscosity (EHL) test rig show that the ? lm thickness of naturally modi? ers to raise viscosity and improve their viscosity index viscous, high-performance EALS is comparable to mineral can break down over time due to mechanical stress, which oils – good news for marine applications that need to keep reduces viscosity and therefore component protection. Lu- equipment lubricated under harsh conditions. But, which bricants that use inherently viscous base oils provide better tests can be used to evaluate lubricant performance? When

Figure 1 assessing lubricants, the test selected should relate to the actual operating conditions of the mechanical element be- ing lubricated. Thrusters and stern tubes are two marine applications where EALs commonly replace mineral oil.

Both applications require lubricants that exhibit: • Good thermal and oxidative stability • Resistance to hydrolysis • Good viscosity to temperature behavior (viscosity index) • Good antiwear and/or extreme pressure protection • Compatibility with the types of elastomers used for seals, hoses, and o-rings.

95 www.marinelink.com MN

94

94

96

96