New Approaches to Inland Infrastructure Renewal

Economical repairs are being applied to rapidly corroding steel and concrete structures in U.S. ports and inland waterways. The new repair systems – PileMedic & SPiRe – might just be what the doctor ordered.

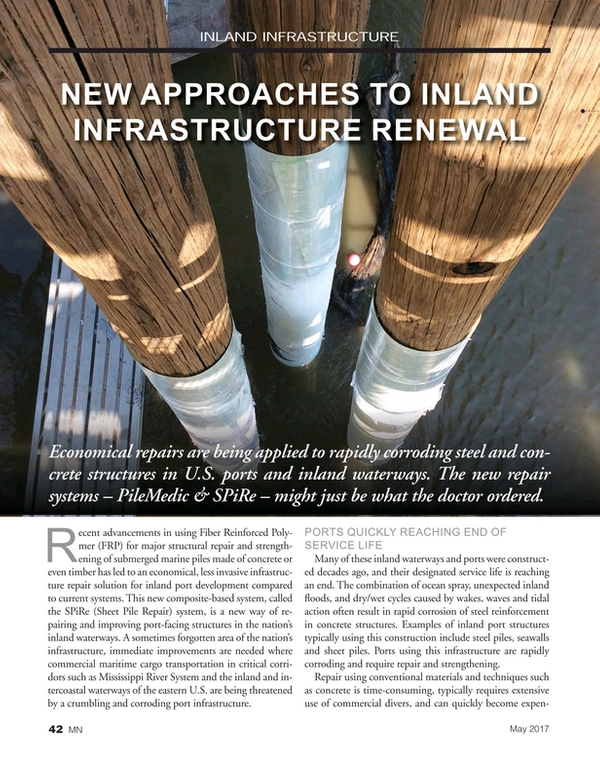

Recent advancements in using Fiber Reinforced Polymer (FRP) for major structural repair and strengthening of submerged marine piles made of concrete or even timber has led to an economical, less invasive infrastructure repair solution for inland port development compared to current systems. This new composite-based system, called the SPiRe (Sheet Pile Repair) system, is a new way of repairing and improving port-facing structures in the nation’s inland waterways. A sometimes forgotten area of the nation’s infrastructure, immediate improvements are needed where commercial maritime cargo transportation in critical corridors such as Mississippi River System and the inland and intercoastal waterways of the eastern U.S. are being threatened by a crumbling and corroding port infrastructure.

Ports quickly reaching end of service life

Many of these inland waterways and ports were constructed decades ago, and their designated service life is reaching an end. The combination of ocean spray, unexpected inland floods, and dry/wet cycles caused by wakes, waves and tidal action often result in rapid corrosion of steel reinforcement in concrete structures. Examples of inland port structures typically using this construction include steel piles, seawalls and sheet piles. Ports using this infrastructure are rapidly corroding and require repair and strengthening.

Repair using conventional materials and techniques such as concrete is time-consuming, typically requires extensive use of commercial divers, and can quickly become expensive. These repairs also are not a long-term solution, as repairing or adding new concrete or steel to a structure will immediately begin to corrode again – just like the original structure.

Corrosion-Resistant Solution

SPiRe is an engineered repair system that’s based on FRP technology that has been used for several years to repair and strengthen worn and damaged marine piles made of timber or concrete using specialized FRP composites. The system is now specifically designed to repair corroded seawalls made of concrete or steel sheet pile, both above and below water.

Repairing these structures using engineered FRP applications offer fast, long-lasting and economical repair alternatives for organizations charged with the maintenance of ports. These lightweight, easy-to-install materials ensure port infrastructure projects can be completed on time, within budget and with minimum disruption of ongoing service.

SPiRe is a patented system provides added strength in addition to an impervious barrier that keeps water and oxygen away from the original structure material. By eliminating the inflow of oxygen, the corrosion rate reaches near zero levels.

This effective solution uses customized, engineered FRP panels made of lightweight honeycomb 3D fabric layered between sheets of resin-saturated carbon or glass fabric. These panels are designed to match the shape of the steel sheet pile or concrete seawall being repaired, and also by design are impervious to water, forming a barrier in front of the original wall that keeps oxygen – and thus further corrosion – away. The type of fabric (glass or carbon) and the orientation of the fibers within the fabric layers are calculated by the design engineer, and is based on the project load requirements.

The SPiRe repair system is engineered to be installed directly on submerged sheet piles without the use of coffer dams or other heavy equipment. Panels are typically four feet wide and as long as necessary. Multiple panels can be joined together either above water (prior to installation) or under water during the installation process.

Inland Infrastructure Renewal: advantage SPiRe

SPiRe repairs and restores sheet piles and sea walls in depths of up to 50 feet. This more than covers most average mean navigation depths for inland and intercoastal ports. SPiRe is an engineered solution that improves structural integrity using fiber reinforced polymer (FRP) technology. It can be engineered to almost any thickness and strength, as required by the original structure. FRP marine pile and sheet pile repair systems can be engineered to handle any kind of large debris the structure or structures may regularly encounter due to floods or tidal surges, as requested by the contracting organization. Some of the repair and strengthening projects in the marine and waterfront space that can benefit from professionally engineered FRP solutions include:

- Uses independently tested, proven PileMedic FRP materials

- Impervious FRP system is corrosion resistant, low maintenance

- Finished installation can be aesthetically coated

- Works on concrete, steel, timber

- Lightweight panels easier to handle, install

- More at PileMedic.com/spire

Read New Approaches to Inland Infrastructure Renewal in Pdf, Flash or Html5 edition of May 2017 Marine News

Other stories from May 2017 issue

Content

- Op/Ed: USCG Forges the Future of Navigation page: 18

- Subchapter M Survey Reports page: 20

- OP/Ed: CVIDA Good for Environment & Economy page: 24

- Rolling on the River with CORBA page: 30

- Gulf of Mexico is Ground Zero for the Jones Act page: 36

- Rapp Marine Deck Equipment Rounds out New Harley Barges page: 40

- New Approaches to Inland Infrastructure Renewal page: 42

- Navigating the ABCs of SCR page: 46

- Tech File: HydroComp NavCad for Optimized Design page: 50