Marine Fuels: Unmasking Gas

By Joe Hudspeth

A primer on the way forward for alternative fuels for marine propulsion.

By now, many of us have been passed by a garbage truck, taken a ride on an airport bus or hailed a taxi cab that is clearly labeled by their respective marketing departments that these vehicles are powered by clean burning natural gas. Even now in our own maritime industry, some trendy operators are looking to make the case for liquefied natural gas (LNG) propulsion systems, others are opting for hybrid-electric solutions, and some are even aiming for full electric configurations. One of the newest alternative fuels and propulsion systems for maritime consideration is the fitting of hydrogen powered fuel cells. Arguments can be made for each, but how do you know if such a system is a good fit for your vessel and operating patterns?

The many and varied online graphics of the latest ‘alternative’ propulsion systems are compelling, but it remains quite challenging to get a close look at the comprehensive system in context to the required physical footprint and infrastructure necessary to make it work. If you are lucky, you might come across a more detailed rendering or find some simple 1-line diagrams that allude to the required components. YouTube has become home to a new genre of “unboxing” events where someone unpacks and walks through all the components contained in the package. These videos are all the rage for those looking for consumer electronics, but the maritime section seems to be lacking. Read on for a closer look what it takes to install a gas based fuel system.

Red and White’s Vision

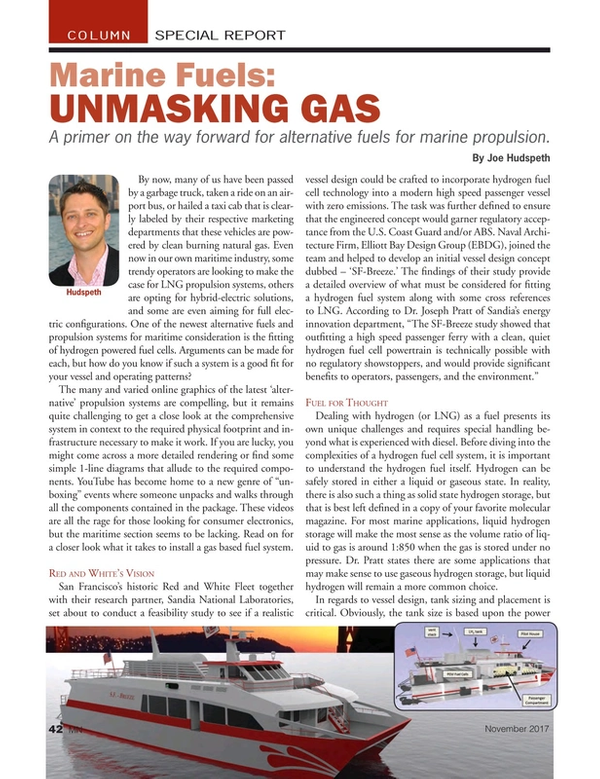

San Francisco’s historic Red and White Fleet together with their research partner, Sandia National Laboratories, set about to conduct a feasibility study to see if a realistic vessel design could be crafted to incorporate hydrogen fuel cell technology into a modern high speed passenger vessel with zero emissions. The task was further defined to ensure that the engineered concept would garner regulatory acceptance from the U.S. Coast Guard and/or ABS. Naval Architecture Firm, Elliott Bay Design Group (EBDG), joined the team and helped to develop an initial vessel design concept dubbed – ‘SF-Breeze.’ The findings of their study provide a detailed overview of what must be considered for fitting a hydrogen fuel system along with some cross references to LNG. According to Dr. Joseph Pratt of Sandia’s energy innovation department, “The SF-Breeze study showed that outfitting a high speed passenger ferry with a clean, quiet hydrogen fuel cell powertrain is technically possible with no regulatory showstoppers, and would provide significant benefits to operators, passengers and the environment.”

Fuel for Thought

Dealing with hydrogen (or LNG) as a fuel presents its own unique challenges and requires special handling beyond what is experienced with diesel. Before diving into the complexities of a hydrogen fuel cell system, it is important to understand the hydrogen fuel itself. Hydrogen can be safely stored in either a liquid or gaseous state. In reality, there is also such a thing as solid state hydrogen storage, but that is best left defined in a copy of your favorite molecular magazine. For most marine applications, liquid hydrogen storage will make the most sense as the volume ratio of liquid to gas is around 1:850 when the gas is stored under no pressure. Dr. Pratt states there are some applications that may make sense to use gaseous hydrogen storage, but liquid hydrogen will remain a more common choice.

In regards to vessel design, tank sizing and placement is critical. Obviously, the tank size is based upon the power demands of the vessel. As hydrogen carries more energy potential than diesel, you may not need an exact one-to-one ratio of comparable capacity. Hydrogen fuel cells are the most efficient in the 20 percent to 30 percent load range so if the load is low, you could burn less hydrogen compared to diesel; but if the application has a high load factor you may need more. Fortunately, hydrogen is much lighter than diesel, but it also requires specialized tanks which can easily add significant weight to the vessel’s lightship draft.

Chill Out

Hydrogen has a very low boiling point, so in order to keep this gas in a liquid state, a Type-C double wall cryogenic insulated tank is needed. The chilled fuel can be bunkered directly into the thermos-like tank from either a truck or shore side bunkering facility. Like the tank, all the piping for the fuel must also keep its cool, so very expensive and specialized vacuum jacketed insulated piping is used. This piping is of course heavier and more complex than fiberglass insulated piping which is suitable for other gas systems such as LNG.

As part of Sandia’s study, both ABS and the Coast Guard found enough similarities to the properties of Hydrogen compared to LNG that the agencies have recommended adoption of the IGF Code as a guideline for installation of a low-flashpoint fuel system. That said; the Coast Guard has yet to make a formal ruling on the placement of gas fuel tanks, but there have been expressions to avoid placement beneath accommodation spaces. For many vessels, this design parameter will force very heavy fuel tanks to be located up high which, of course, is not optimal for stability.

The tanks can be placed below accommodation spaces, but the system will become more complex and expensive. Some designs such as that used to build the LNG-powered Harvey Gulf have found a safe place to position the tank below the aft cargo deck or in Robert Allan’s RANGLer tugboat, the tank is located below deck forward. Designers will have to run the stability calculations and find creative ways to deal with all of these gas storage complexities.

The How of Hydrogen

The basic hydrogen fuel cell propulsion system will consist of a propulsor of your choice (prop, thruster, or jet), permanent magnet AC traction motor, a fuel storage tank, and some fuel cells. At its most basic level, a hydrogen fuel cell is simply a box that produces electricity through an electro-chemical reaction of the fuel and oxygen when the elements come in contact with the cell’s catalyst layers and membrane. The process literally involves splitting molecules and the net result is a product of DC power and some waste in the form of H2O.

The DC power that is produced has variable voltage depending on the load demand on the fuel cell; thus a DC to DC converter is required to condition the power. The DC power will then pass through a filter before hitting an inverter to finally create the needed alternating current for the AC motors. The number of fuel cells needed depends on the size of each cell and the calculated power demand of the propulsors.

Vaping isn’t Cool

The fuel cell can only burn hydrogen in a gaseous state, so before arrival at the fuel cell the hydrogen must first be vaporized. The vaporizer is considerable in size and weight, but also comes with a requirement for air or water to facilitate the needed heat. The EBDG team has suggested that some of the waste heat from the fuel cell’s water cooling loop could be recycled to run the vaporizers. Placement of the fuel cells themselves does offer flexibility as long as size, weight, stability, and ventilation can be properly considered. The cells can even be stacked by mounting in racks. Good ventilation will be needed to supply the proper oxygen for the fuel cells to work, but there will also be considerable heat generated and adequate air conditioning must be installed.

Don’t Pass Gas

Adding an LNG or hydrogen fueled propulsion system may prove to be a good fit because the environmental benefits are high. The challenge will remain for builders and naval architects to produce safe and viable designs. Eventually, regulatory bodies will need to establish guidelines. While referencing the IGF code can offer some requirements for the fuel system, all boat builders will agree that when blended regulations exist it is easy to find frustration as conflicts will undoubtedly occur.

The new gas-based fuel systems are safe, but vessel designs must consider proper hazardous zones and incorporate satisfactory structural fire protection, fire suppression systems and a defined operating procedure. The SF-Breeze and other LNG powered vessels will surely help to chart this course for our industry. More information and a copy of the full report on SF-BREEZE can be found online at http://energy.sandia.gov

The Author

Joe Hudspeth is Vice President of Business Development at All American Marine, Inc., a manufacturer of high speed passenger ferries, excursion vessels, and work boats, in Bellingham, Wash. Hudspeth has been involved with maritime sales, marketing and product development since 2000. He currently serves as a regional co-chairman for the Passenger Vessel Association and participates on several committees concerned with marine industry issues.

Reach him at [email protected]

(As published in the November 2017 edition of Marine News)

Read Marine Fuels: Unmasking Gas in Pdf, Flash or Html5 edition of November 2017 Marine News

Other stories from November 2017 issue

Content

- Interview: Rear Adm. Mark Buzby, US Maritime Administrator page: 12

- Preparation Propels Financial Peace of Mind page: 20

- Catching a Jones Act Seaman’s 'Golden Parachute' page: 24

- Leadership and Subchapter M page: 28

- Op/Ed: Making the Mississippi River Mightier page: 34

- Op/Ed: Facts Do Matter - A Defense of the Jones Act page: 38

- Marine Fuels: Unmasking Gas page: 42

- A Sea Change for Shipbuilding page: 46

- GoM Stakeholders Energized Despite Lingering Oil Bust page: 52

- Federal Waterways Infrastructure Outlook page: 62

- Brunswick: Ramping up Quality for the Long Haul page: 70

- Marine Piping: It's Not Rocket Science page: 76

- Connecting Boatbuilders to the New Gold Standard page: 82

- Ferry Operations: A Tragedy Averted page: 86

- Connectivity for Brown Water Operations page: 90

- New Grease Extends Life, Lowers Temp of Tugboat Shaft Bearings page: 92

- The Digital Voyage: 'Onboarding' Shipping to the Digital Age page: 94