North Carolina Ferries Change Course for the Future

By Joseph Keefe

Shoaling shifts NCDOT’s propulsion needs, prompting a sea change. Thrustmaster waterjets step in to carry the day.

In Swansboro, N.C., boatbuilder U.S. Workboats (formerly Armstrong Marine) is assembling the linchpin of the North Carolina Department of Transport’s (NCDOT) business plan for its future Outer Banks ferry services. Separately, in both Hatteras and Ocracoke, crews are preparing to break ground on new parking additions and visitor facilities.

The Ocracoke Express passenger ferry project – made necessary by the shifting and unpredictable shoaling on North Carolina’s Outer Banks – will, starting this summer, change forever the way tourists and visitors get to and from these national treasures.

In a nutshell, the Ocracoke Express passenger ferry is a new service from NCDOT designed to alleviate summertime congestion issues on the existing Hatteras-Ocracoke car ferry route. Passengers will be able to make a reservation and walk onto a ferry that will take them into the heart of Ocracoke Village in just over an hour, bypassing the waits that often occur on the vehicle ferries.

Local Challenges: Problem Solved

With a projected delivery date for late June 2018, the changes will come not a minute too soon. That’s because Hatteras Inlet is a very dynamic body of water. It has changed many times – and dramatically – over the past 15 years, said Jed Dixon of the North Carolina Ferry Division. Dixon, speaking at the annual PVA Convention in Savannah, explained, “The route previously run by the NC Ferry has to change because of severe shoaling. Now they have to go out and around the whole inlet system to get to Ocracoke Island. This shoaling has created real hardships for our operations.”

Also according to Dixon, dredging efforts by USACE had been unsuccessful because of the nature of the shoaling in the area and weather patterns. In fact, and in 2013, a multimillion dollar dredging project was undertaken. “And the day they finished it, we couldn’t get a ferry across it – it filled in that fast,” said Dixon, who insists, “We need to start working outside the box to see how we can do business differently.” The historic route was four miles; the new ‘horseshoe’ route is about 8 miles. And that has had a real impact on operations. For starters, it increased the cost of labor and fuel by $250,000 per month.

Presently, the horseshoe/outer route forces NC Ferry to go from 52 departures per day to 42 departures per day, using the same number of vessels. And it doubled the transit time for this route between Hatteras Island and Ocracoke Inlet to one hour. The local impact was significant – local business and tourism was down because NC Ferry transport numbers were down – and the system couldn’t move as many people and vehicles daily. It was suggested that NC Ferry start a passenger only route. The solution was a high speed ferry from Hatteras to Silver Lake Park.

Today, NCDOT only runs car ferries; they don’t have a high speed ferry. Fortunately, and in this case, the state received $5 million from the federal government, in part because much of the area in the Outer Banks that passengers visit is also federal land. The $9 million price tag therefore is being underwritten by the Federal Lands Access Program grant with the balance being an appropriation from the General Assembly.

Critical Design Parameters

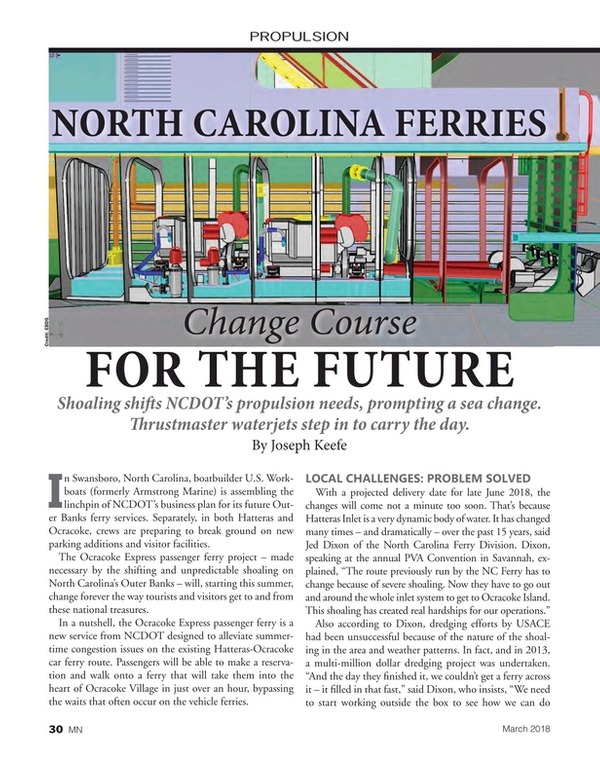

According to Elliott Bay Design Group (EBDG) naval architect Brian King, the ferry’s intended service conditions demanded attention to many parameters. As such, he told MarineNews, the boat was extensively ‘3D modeled’ during the design phase. And, he said, stability, ocean conditions, speed and reserve buoyancy were of paramount concern. In particular, the ferry was designed by EBDG to have an exceptionally higher freeboard (+18”) than most conventional harbor fast ferries. Also with a nod towards the new offshore routing, NC Ferries dictated that it be constructed more robustly. A long fetch into waters at places along the route makes the prevailing weather quite challenging.

Beyond those challenges, the vessel’s design specified water jets because NC Ferry needed 28 KT in sustained speeds because of the new, longer routing and the need to return to a schedule of full service departures. Finally, and of no less importance, the use of waterjets was necessary because of the local silting, shoaling and turbidity of the sound waters. In this case, Thrustmaster’s Waterjets won out over a well-known competitor, in part, because of US-build requirements (with federal money involved in the funding).

Jordan Tilton, Sales Manager, Waterjets for Thrustmaster of Texas, says that there was far more to it than that. While the initial plan had been drawn for a more familiar name in the market, Tilton says that the Thrustmaster decision just made good business sense. “We looked at our performance curves and theirs, and while our competitor didn’t meet the buy America clause, honestly, the 170HP Jet that is being installed on that boat is actually a little bit larger in diameter (by about 30mm), so it is actually a better load carrying jet, just in terms of diameter. Also, the fact that we had local support here in the United States had a lot to do with it. We service everything out of Houston.”

Thrustmaster of Texas, perhaps better known for its larger thrusters in the offshore energy markets, bought the U.S. manufacturing and licensing rights for its waterjet designs back in August of 2014. In part, that savvy move had a lot to do with diversifying its product lines in the face of morbid offshore energy markets. Today, Doen is still its own entity in Australia and Thrustmaster regularly works with and consults their engineering teams regularly.

Doen has been in business for 40 years – all over the world. A proven brand, the Thrustmaster version of these sturdy waterjets are manufactured right here in the United States. In fact, and for those operators who might not be as familiar with that name, there are actually as many as 400 Doen waterjets in the US Navy’s 11 meter rib fleet – but people just don’t know it.

The Thrustmaster 170HP jet is of very simple build. All internal components are stainless steel – the impellor and driveshaft – on the outside, marine grade aluminum. Addressing the local North Carolina Outer Banks conditions, Tilton told MarineNews, “In terms of shallow water and turbidity, we have a lot of boats in Alaska; specifically in places notorious for rocks and silt that can be sucked through intakes. We’ve never had an instance there where we couldn’t refurbish an impellor to its original specs.”

According to Tilton, in the short time since Thrustmaster acquired the Doen designs, it has sold and installed more than 40 in North America. And he said his firm had “a few projects on drawing board.” Fully compatible with all gears and whatever engine is in front of it, in this case the four waterjets are driven by C-18 CAT’s in a quad 803 arrangement through ZF gears – the latter component reportedly chosen, in part, because of its weight savings. The vessel is certified to EPA tier 3 emissions standards.

Finally, the four Thrustmaster Waterjets steer 30 degrees port and starboard and they are reversible. Multiple Joysticks in the wheelhouse and on the wings for docking round out a very complex and, at the same time, user-friendly control system.

Course Correction with Waterjets

Sometimes, it just isn’t possible to beat Mother Nature. When dredging couldn’t do the trick, NCDOT turned to a different kind of ferry, a new and improved business plan, and a propulsion system ready for all challenges. American-built Thrustmaster waterjets will soon be solving NCDOT’s transport problems in the unpredictable and unforgiving waters off the Outer Banks. And, if that solution can work there, then there probably aren’t too many more workboat challenges it can’t handle anywhere else.

NCDOT Passenger Vessel at a Glance

LOA: 92'

Beam: 28'

Draft: 4'

Gears: ZF

Maximum Speed: 32 KT

Cruising Speed 28 KT

Engines = Cat C18, 803 HP x 4

Passengers: 127

Endurance:

one day of service

Fuel Capacity:

2,200 gallons (95%)

Generators = Northern Lights 40 kW x 2

Local engine Distributor: Gregory Poole

(As published in the March 2018 edition of Marine News)

Read North Carolina Ferries Change Course for the Future in Pdf, Flash or Html5 edition of March 2018 Marine News

Other stories from March 2018 issue

Content

- Insights: Pat Folan, Tug & Barge Solutions page: 14

- Subchpter M: The Clock is Ticking page: 20

- Op/Ed: Disconnect from River to Washington page: 24

- Inland Workboats Have Much to Gain from Diesel Electric Propulsion page: 26

- North Carolina Ferries Change Course for the Future page: 30

- Emissions Regulations: 'It's Not Easy Being Green' page: 34

- YANMAR Cruises Into Alaska with Power to Spare page: 38

- Offshore Wind Drives Demand for US Support Vessels page: 42

- Exhaust Economizers: A Silent Contributor to Green Technology page: 45

- Dellner Brakes: Serving Inland and Coastal Waterways Markets page: 48

- Marine News Boat of the Month: March 2018 page: 50