DECK MACHINERY: A Step Up in Safety

How NABRICO’s FASST Winder Winch created a safer work environment.

Great ideas can come anytime, from anyone. For NABRICO, a field team member’s understanding of the physical exertion required to operate a ratchet handle, while also acknowledging the value in the older spoked hand wheel configuration, brought about both innovation and new standard of winch safety to the market in the form of the FASST Winder Winch.

Maximizing Return on Energy

Rather than using a ratchet handle, which required more physical effort, the new winch incorporates a handle and foot pedal at the right location to maximize return on energy, harnessing the unused power of the operator’s arms, legs and gravity. The result: a FASST Winder would take stress off the operator’s back and shoulders by engaging the leg muscles in the process.

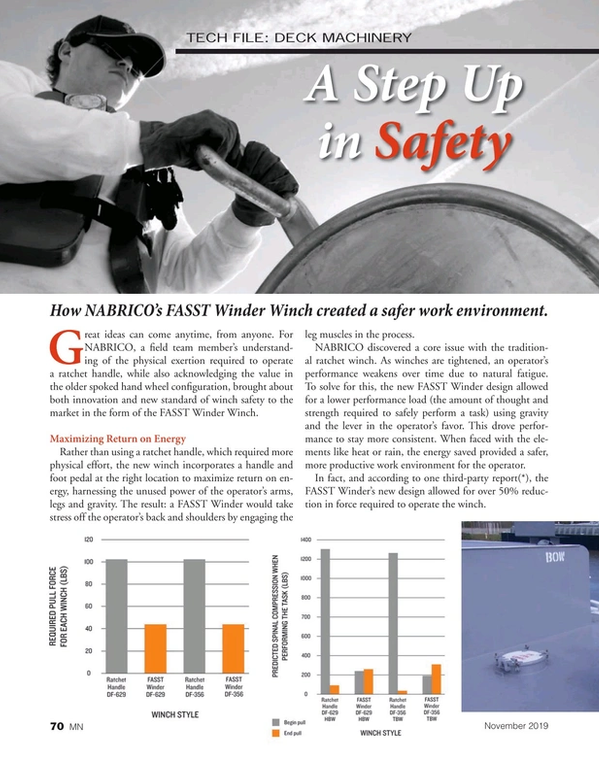

NABRICO discovered a core issue with the traditional ratchet winch. As winches are tightened, an operator’s performance weakens over time due to natural fatigue. To solve for this, the new FASST Winder design allowed for a lower performance load (the amount of thought and strength required to safely perform a task) using gravity and the lever in the operator’s favor. This drove performance to stay more consistent. When faced with the elements like heat or rain, the energy saved provided a safer, more productive work environment for the operator.

In fact, and according to one third-party report (*), the FASST Winder’s new design allowed for over 50% reduction in force required to operate the winch.

Lower Stress = Reduced Accidents

Because of the FASST Winder’s design requires less effort and engages other muscle groups, the winch allows for four times less back stress and reduces shoulder stress by half, compared to the ratchet model, according to a third-party report. In a nutshell, the FASST Winder’s simple design reduces the risk of injury through key factors, as follows:

- No Cheater Pipe or Extension Handle: Adequate cable tension can be generated with the FASST Winder with the newly designed handle and foot pedal, meaning no “Cheater Pipe,” “Ratchet Handle Extension,” or “Johnny Bar” is needed to create extra leverage.

- Four Points of Contact: The FASST Winder model winch can be operated with four points of contact – both hands on the handle, one foot on the barge surface, and one foot on the pedal.

As the FASST Winder nears three years in the market, NABRICO has seen first-hand how this new design is improving the work environment for operators. NABRICO’s Vice President and General Manager, Clint Bryan, recalls his most memorable sales call:

“We arrived at a customer’s venue and showed the FASST system installed on a barge winch connected to another ratcheted barge winch. We had a small, skeptical crowd of four to five people. After a couple of minutes, many of them stepped away and got on their phones. The next thing you know, there are twenty people there and one of them was showing the winch off for us. We just stood there and watched; it was better than we had hoped for.”

For NABRICO, innovation is driven by their entrepreneurial culture. A field team member’s great idea transformed into a new product, increasing performance and creating a safer work environment.

(*) ESIS Risk Control Report, October 2016. Prepared by ESIS Health, Safety, and Environmental.

This article first apeared in the November print edition of MarineNews magazine.

Read DECK MACHINERY: A Step Up in Safety in Pdf, Flash or Html5 edition of November 2019 Marine News

Other stories from November 2019 issue

Content

- BY THE NUMBERS: the OSV Markets page: 10

- INSIGHTS: Sean Fernstrum, President, R.W. Fernstrum page: 14

- SAFETY: Dollars & Sense page: 26

- ISO: Affordable & Reliable Workboat Comms page: 30

- BOATBUILDING: From Estonia with Love page: 54

- REGULATORY REVIEW: Subchapter M page: 60

- DECK MACHINERY: A Step Up in Safety page: 70

- Blount Boats: Ferries, Offshore Wind both Dominate Present, Future page: 72

- Digital Developments Continue Apace in the Workboat Space page: 76

- DOMESTIC DREDGING: U.S. Ports Require a Diverse Fleet page: 80

- Navigating the Rough Waters of Marine Certification page: 88