Tech File: Grain Monitoring System for Loaded Barges

Purpose-built for storage challenges brought on by climate change and geopolitical tensions, TeleSense has introduced its cellular SensorSpear Monitors to protect post-harvest grain.

TeleSense, a post-harvest grain monitoring innovator, recently introduced a Cellular SensorSpear intended to give grain managers and barge operators an easy and reliable way to accurately monitor stored grain, ensuring grain quality while reducing spoilage and safety concerns.

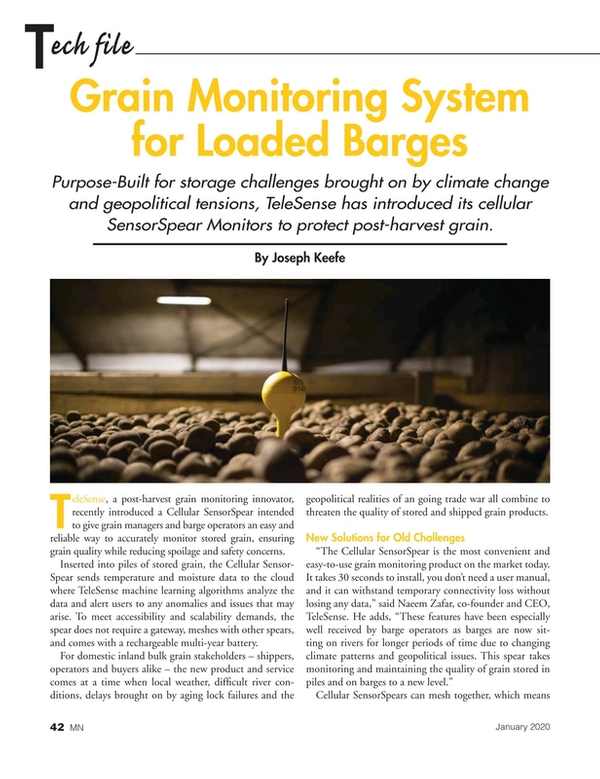

Inserted into piles of stored grain, the Cellular SensorSpear sends temperature and moisture data to the cloud where TeleSense machine learning algorithms analyze the data and alert users to any anomalies and issues that may arise. To meet accessibility and scalability demands, the spear does not require a gateway, meshes with other spears, and comes with a rechargeable multi-year battery.

For domestic inland bulk grain stakeholders – shippers, operators and buyers alike – the new product and service comes at a time when local weather, difficult river conditions, delays brought on by aging lock failures and the geopolitical realities of an going trade war all combine to threaten the quality of stored and shipped grain products.

New Solutions for Old Challenges

“The Cellular SensorSpear is the most convenient and easy-to-use grain monitoring product on the market today. It takes 30 seconds to install, you don’t need a user manual, and it can withstand temporary connectivity loss without losing any data,” said Naeem Zafar, co-founder and CEO, TeleSense. He adds, “These features have been especially well received by barge operators as barges are now sitting on rivers for longer periods of time due to changing climate patterns and geopolitical issues. This spear takes monitoring and maintaining the quality of grain stored in piles and on barges to a new level.”

(Photo: TeleSense)

(Photo: TeleSense)

Cellular SensorSpears can mesh together, which means the spears communicate with each other, so that only one spear communicates with the cloud, thereby reducing data costs. Examining trends in the data and providing insight to anticipate storage issues, TeleSense machine learning algorithms provide users with the smart alerts they need to easily and effectively manage grain quality.

In a nutshell, the spear pairs with the TeleSense App, where users can adjust reporting frequency, see the current and historical trends of every sensor, and, more importantly, quickly view the health of an entire grain storage operation.

Like any other food product, grain will eventually rot and spoil if it’s not stored properly. Currently, the grain supply chain experiences a lot of waste due to spoilage during storage and transport. The best way to reduce spoilage is to catch it early and take preventative measures. In order to catch it early, there needs to be a monitoring system in place to sense the spoilage. According to Naeem Zafar, up until now, there have been limited solutions for monitoring stored grains, and no one had found an easy and cost-effective way to monitor grain barges and grain piles. And, this is important for many reasons.

Zafar told Marine News, “The grain industry is facing challenges on multiple fronts. This year, grain barges were stalled for weeks by flooding on the Mississippi river. Due to changing weather patterns from climate change, this challenge is expected to continue, or worsen. Compounding the issue, many of these barges were held even longer due to the trade dispute with China. Currently, these barges are not monitored. There is no way to know what is happening inside them, so there is no way to take action when a problem develops. Each of these barges contains one million dollars worth of grain, so it’s a big deal when one is lost due to spoilage.”

It should be no surprise that the longer grain is stored, the greater the risk of spoilage. Hence, the owner will want to sell it quickly; all other things being equal, such as current and future grain prices. Beyond this, the longer grain is stored, the more it will cost to maintain its quality through ventilation, heating, gassing and other procedures. For farmers and barge operators alike, being stuck with grain in long-term storage is not ideal, but is oftentimes inevitable.

(Photo: TeleSense)

(Photo: TeleSense)

Cold to Hot; Ventilate Not / Hot to Cold; Ventilate Bold

Conventional mariner’s knowledge, when moving from one part of the world to another with any bulk cargo or hygroscopic sensitive goods, is rather simple. “Cold to hot; ventilate not. Hot to cold ventilate bold.”

In a nutshell, this time-honored adage describes how to predict the problem of condensation just as well today, as it did 100 years ago. The Cellular SensorSpear monitors ‘post-harvest’ grain, enabling and providing the data and insight necessary to make good storage decisions that do protect the grain.

Grain produces heat during storage due to natural metabolic processes. When warm grain is stored against a barrier which is in contact with something cold, such as the hull of a vessel in contact with water, it produces condensation. Condensation produces areas of high moisture content, and high moisture levels create an inviting climate for mold, fungus, and insects – which all cause spoilage.

By installing TeleSense sensors in strategic areas of a mass of stored grain, grain managers can see the daily changes in the temperature and moisture of that grain. When grain begins to spoil, it will begin to heat up and develop areas of spoilage known as ‘hotspots.’ These areas can become so hot that they can actually ignite. Zafar adds, “By monitoring the behavior of the temperature and moisture levels we can help grain managers make informed decisions about when to ventilate, gas or mix their grain-actions which stop spoilage.”

To meet accessibility and scalability demands, the spear does not require a gateway, meshes with other spears, and comes with a rechargeable multi-year battery. This means that the spear is designed to be simple to use and cost effective. It is an all-in-one unit which can be installed and working in under 30-seconds. As many as 20 spears can communicate together in a meshed network, via just one cellular data connection.

Naeem Zafar, co-founder and CEO, TeleSense (Photo: TeleSense)

Naeem Zafar, co-founder and CEO, TeleSense (Photo: TeleSense)

Time is Money

If time is money, then a barge load of grain exhibiting spoilage warning signals is a perfect example of when getting that grain to market quickly is job one. With multiple loaded barges in a fleet situation, barge loads can be prioritized with regard to the urgency to get one or more to market, sooner than another. All of this can be handled from afar, using technology that leverages the cloud. Hence, an idle loaded barge can be monitored from the office, miles away.

Pricing models for this new technology can vary. For example, currently there are options for both one time purchases as well as subscription/rental models. The Cellular SensorSpear and TeleSense App work together to provide grain handlers an innovative and functional way to monitor their grain. And, not a moment too late.

(Photo: TeleSense)

(Photo: TeleSense)

Read Tech File: Grain Monitoring System for Loaded Barges in Pdf, Flash or Html5 edition of January 2020 Marine News

Other stories from January 2020 issue

Content

- Red and White and Green All Over page: 12

- Fishing for Trouble page: 16

- An Ever-vigilant Focus on Passenger Vessel Safety page: 18

- Ferry Industry Sets Pace on Critical Solutions page: 20

- Vessel Safety: US House Subcommittee Seeks Faster Implementation page: 24

- Vessel Inspections: It's All About Safety page: 28

- Safely Navigating the Winds of Change page: 34

- Water Audits at Sea page: 39

- Tech File: Grain Monitoring System for Loaded Barges page: 42