Lubrication Selection Fundamentals

As an operator of vessels, you understand that lubricants play an important role in helping you achieve your operational objectives. Yet, finding the right one can be overwhelming since there’s an almost unlimited number of different lubricant formulations. An understanding of lubrication chemistry, performance expectations and operational objectives will help you select a lubricant that will improve operations and lower your overall costs.

Lubrication benefits

The basic function of a lubricant is to reduce friction by separating interacting surfaces. In operation, a lubricating oil or lubricating grease is applied to the surface and monitored for effectiveness. Possible lubrication benefits include:

- Create surface separation

- Reduce friction between components

- Minimize or prevent wear

- Increase efficiency

- Reduce energy consumption

- Extend service life of the equipment

- Improve reliability

- Noise reduction

- Cut maintenance and repair costs

- Improve machine safety

- Prevent rust and corrosion

- Cleanse equipment of fouling/contaminants

- Prevent or remove deposits, sludge, varnish

- Remove heat from system

- Perform work (e.g., hydraulic fluids)

In addition, you might have external considerations, like meeting environmental certifications that leads you toward a specific formulation. However, even in these circumstances, the lubricant selected significantly impacts the overall operation.

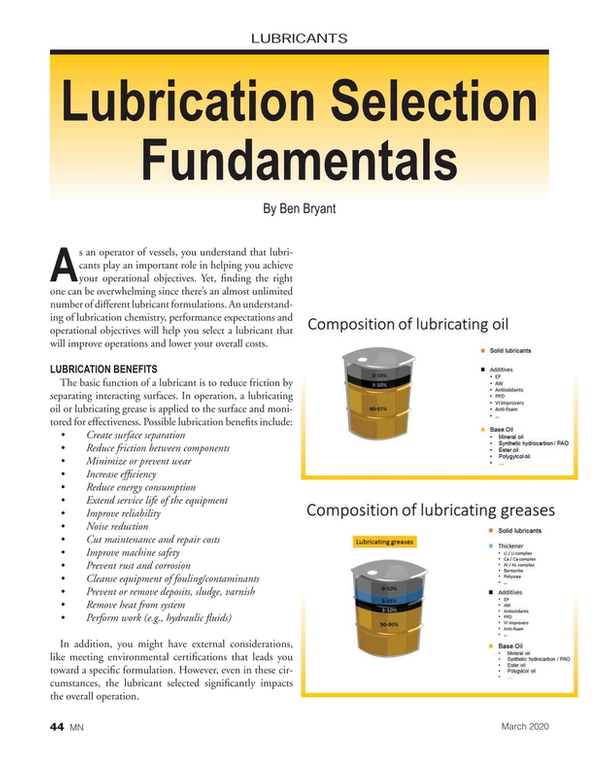

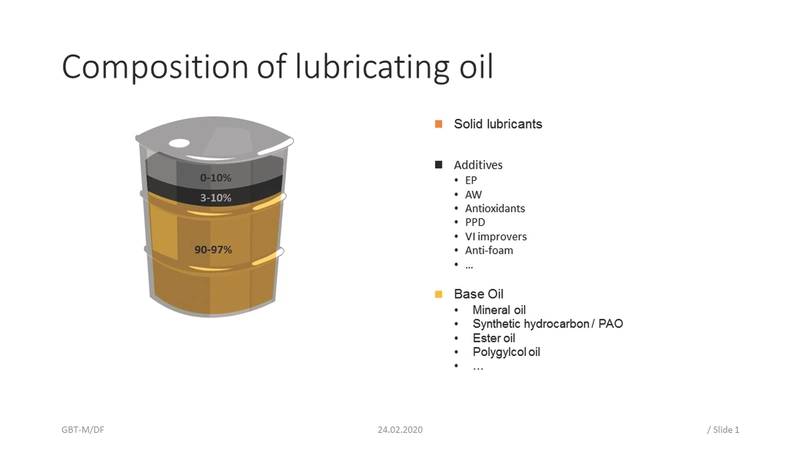

Composition of lubricating oils and greases

A lubricating oil consists of a base oil, additives and – in some cases – solid lubricants. A lubricating grease is created by adding thickener to the oil.

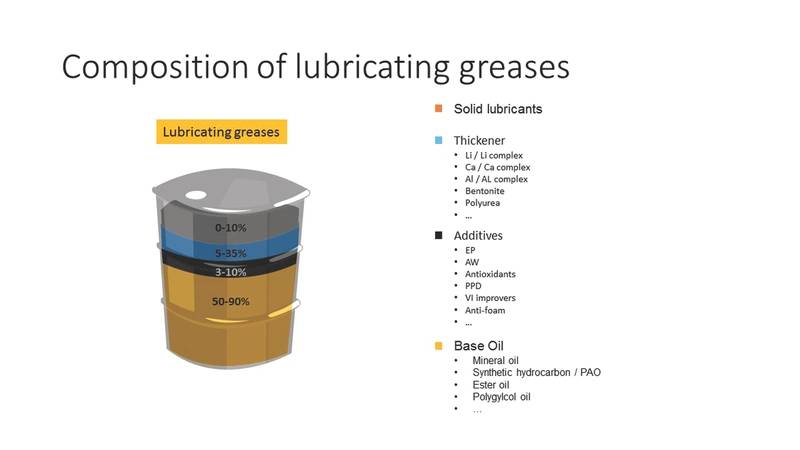

Options for base oils include mineral oil, synthetic hydrocarbons (PAO), esters, polyglycols (PAG), silicon and perfluorinated polyethers (PFPE) – each with advantages and disadvantages. The correct base oil will depend on your operational objectives. If your overall goal is the lowest purchase price, then mineral-oil based lubricants are the standard. However, as you look to lubricants to help improve your operations or meet environmental standards, the performance characteristics of each of the other base oil types should be considered. A sample of performance characteristics for four base oil types is in the table below.

Additives either improve the chemical and physical characteristics of the oil or they protect mechanical elements within the contact zone. Examples of lubricant additives that improve oil performance are antioxidants that extend the life of the oil, pour-point depressants to impart better low-temperature flow, viscosity improvers to reduce the variation in viscosity over changing temperatures and detergents to minimize sludge and varnish. Additives that work in the contact zone include phosphorous-based anti-wear additives that form a protective layer on top of metal surfaces, sulphur-based extreme pressure additives that prevent spot welding under high loads and corrosion inhibitors to reduce rust.

It’s important to achieve proper additive balance because different combinations either work synergistically (work together) or antagonistically (work in opposition). Additives are also fighting for space on the metal surface. For example, too high a concentration of corrosion inhibitors may reduce the ability of an extreme pressure additive from doing its job. Solid additives such as graphite and molybdenum disulfide (Moly) can improve performance in highly loaded gears. These additives maintain surface separation even when the lubricant has been displaced under pressure. Solid additives are beneficial in some applications, but a well-balanced lubricant with EP additives is more often selected. Thickeners for greases can be divided into two categories: soaps and non-soaps. Soap thickeners include lithium, calcium, barium, aluminum and sodium soaps. Descriptors such as “simple,” “stearate” and “complex” added to the name of the soap refer to the complexity of the grease structure created during the production

process. Complex greases usually perform better than simple greases but tend to cost more due to their increased production time. Non-soap thickeners include bentonites, polyureas and plastics.

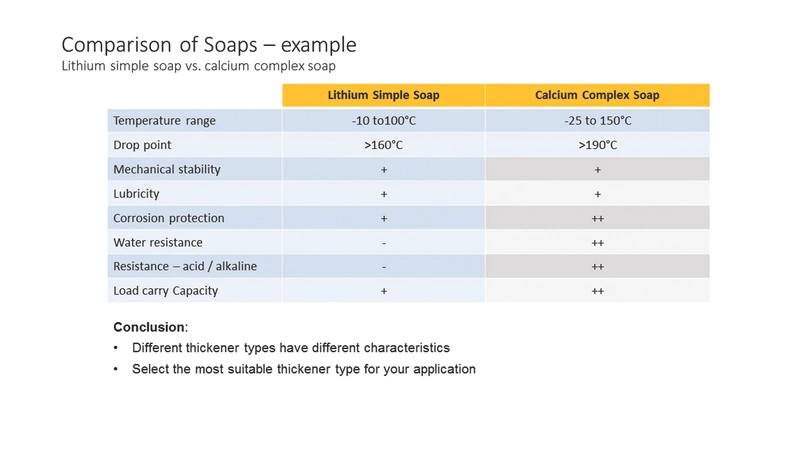

The thickener’s role is to thicken the oil, control the oil’s release and seal the friction point from contamination. However, each type of thickener also imparts performance characteristics onto the grease. Below is a comparison of lithium simple soap and calcium complex soap. Notice that the complex calcium soap has better performance characteristics regardless of the additives or base oil used.

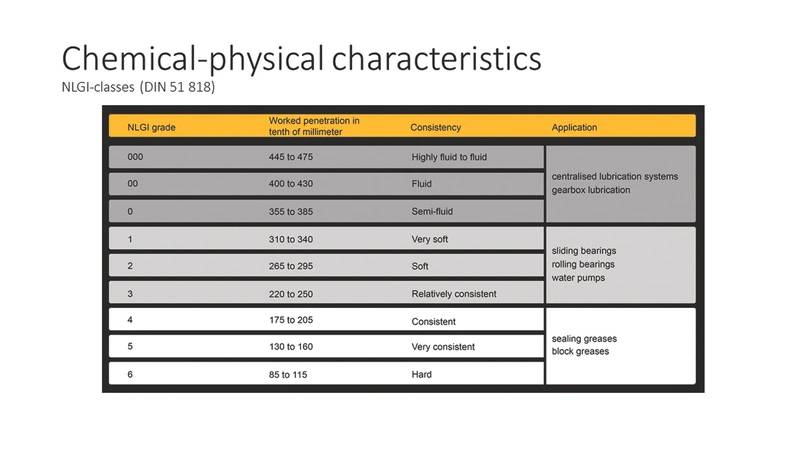

The NLGI scale of a grease refers to the amount of thickener added to the base oil. A “soft grease” has less thickener than a “stiff” grease. Soft greases are often used in automatic lubrication systems while stiffer greases can be found where the grease requires vertical adhesion.

Tribology and the “Tribo System”

Tribology – the study of friction, lubrication and wear – has become the basis for selecting the correct lubricant in today’s demanding environment. Before the proper lubricant can be selected for a specific application, the tribological system must be identified to its fullest extent. Analyzing the type of motion, speed of the components, operating temperatures, loads and the application’s operating environment will lead to proper selection of the lubricant.

Types of motion that create friction are defined as rolling, sliding, combined rolling/sliding and boring. The choice of base oil and additives will determine how well the lubricant protects against each type of friction. As an example, PAG base oils have better performance in areas of sliding friction than mineral oils or PAOs.

The speed of the mechanical element will impact the viscosity of the base oil chosen as well as the NLGI grade of a grease. The faster the speed, the lower the viscosity and/or NLGI that should be selected.

The choice of lubricant will be affected by the operating temperature. The base oil chosen can improve performance at high temperatures, low temperatures and changing temperatures. Additives can improve the oxidative performance of the base oil. The thickener system may have a big impact on the performance.

Load will determine the viscosity and whether anti-wear or extreme pressure additives are required.

Finally, operating environments including ambient temperature, moisture, contaminates, exposure to vapors or chemicals and whether the element is operating under pressure (deep sea) or in a vacuum (gyro stabilizers) must be considered.

Conclusion

Understanding that the choice of lubricant chemistry and formulations can have a substantial impact on the performance of your vessel operation is the first step toward an optimal lubrication program. A lubrication engineer can assess the tribological conditions of each application and make recommendations that balance the price of the lubricant with the return on investment derived from reduced lubrication usage, lower labor costs, extended lubrication intervals, safety and asset life extension.

Read Lubrication Selection Fundamentals in Pdf, Flash or Html5 edition of March 2020 Marine News

Other stories from March 2020 issue

Content

- Insights: Gavin Higgins, CEO, Everett Ship Repair page: 14

- OpEd: STCW Requirements Should Support Maritime Decarbonization page: 18

- The National Freight Strategic Plan and the Inland Waterways page: 22

- Rewrite the Rules: The Path to Zero Emissions page: 30

- EPA Tier 4: Difficult and Contentious, 12 Years and Counting page: 34

- Winter Work on the Great Lakes page: 42

- Lubrication Selection Fundamentals page: 44

- Tech File: Reliable Lifts page: 50