Page 44: of Marine News Magazine (October 2020)

Shipbuilding & Repair

Read this page in Pdf, Flash or Html5 edition of October 2020 Marine News Magazine

ech file

T

New Towboat Gets a Complete

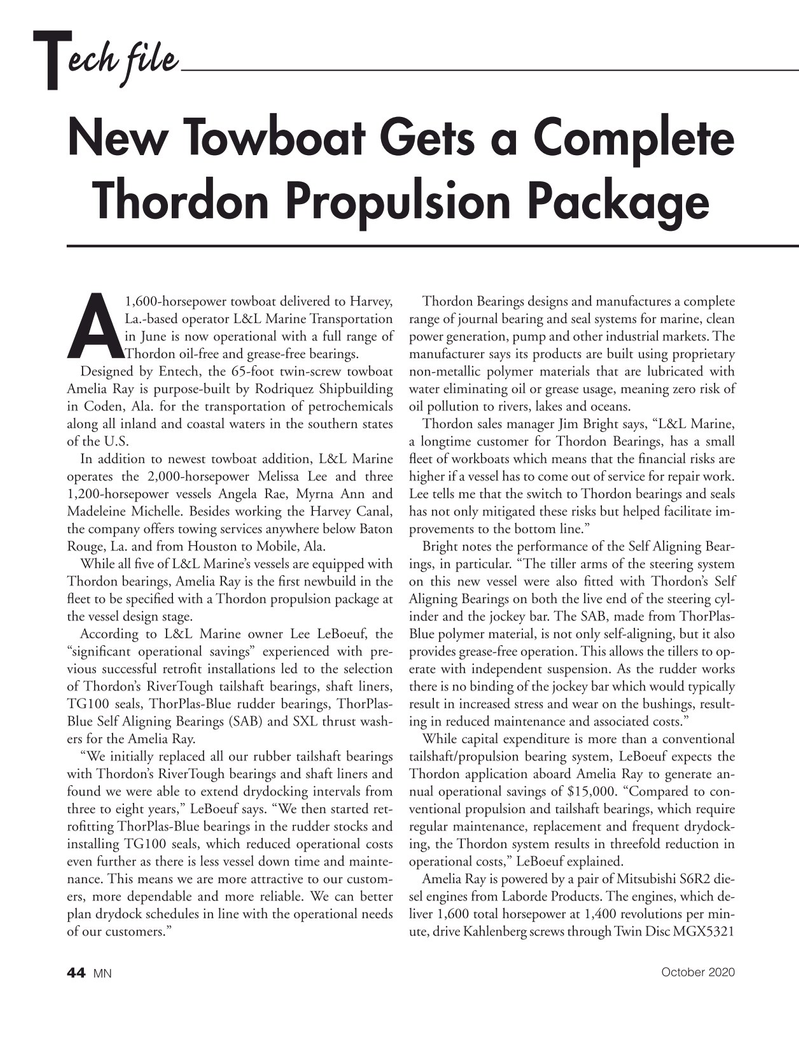

Thordon Propulsion Package 1,600-horsepower towboat delivered to Harvey, Thordon Bearings designs and manufactures a complete

La.-based operator L&L Marine Transportation range of journal bearing and seal systems for marine, clean in June is now operational with a full range of power generation, pump and other industrial markets. The A

Thordon oil-free and grease-free bearings. manufacturer says its products are built using proprietary

Designed by Entech, the 65-foot twin-screw towboat non-metallic polymer materials that are lubricated with

Amelia Ray is purpose-built by Rodriquez Shipbuilding water eliminating oil or grease usage, meaning zero risk of in Coden, Ala. for the transportation of petrochemicals oil pollution to rivers, lakes and oceans.

along all inland and coastal waters in the southern states Thordon sales manager Jim Bright says, “L&L Marine, of the U.S. a longtime customer for Thordon Bearings, has a small

In addition to newest towboat addition, L&L Marine ? eet of workboats which means that the ? nancial risks are operates the 2,000-horsepower Melissa Lee and three higher if a vessel has to come out of service for repair work. 1,200-horsepower vessels Angela Rae, Myrna Ann and Lee tells me that the switch to Thordon bearings and seals

Madeleine Michelle. Besides working the Harvey Canal, has not only mitigated these risks but helped facilitate im- the company offers towing services anywhere below Baton provements to the bottom line.”

Rouge, La. and from Houston to Mobile, Ala. Bright notes the performance of the Self Aligning Bear-

While all ? ve of L&L Marine’s vessels are equipped with ings, in particular. “The tiller arms of the steering system

Thordon bearings, Amelia Ray is the ? rst newbuild in the on this new vessel were also ? tted with Thordon’s Self ? eet to be speci? ed with a Thordon propulsion package at Aligning Bearings on both the live end of the steering cyl- the vessel design stage. inder and the jockey bar. The SAB, made from ThorPlas-

According to L&L Marine owner Lee LeBoeuf, the Blue polymer material, is not only self-aligning, but it also “signi? cant operational savings” experienced with pre- provides grease-free operation. This allows the tillers to op- vious successful retro? t installations led to the selection erate with independent suspension. As the rudder works of Thordon’s RiverTough tailshaft bearings, shaft liners, there is no binding of the jockey bar which would typically

TG100 seals, ThorPlas-Blue rudder bearings, ThorPlas- result in increased stress and wear on the bushings, result-

Blue Self Aligning Bearings (SAB) and SXL thrust wash- ing in reduced maintenance and associated costs.” ers for the Amelia Ray. While capital expenditure is more than a conventional “We initially replaced all our rubber tailshaft bearings tailshaft/propulsion bearing system, LeBoeuf expects the with Thordon’s RiverTough bearings and shaft liners and Thordon application aboard Amelia Ray to generate an- found we were able to extend drydocking intervals from nual operational savings of $15,000. “Compared to con- three to eight years,” LeBoeuf says. “We then started ret- ventional propulsion and tailshaft bearings, which require ro? tting ThorPlas-Blue bearings in the rudder stocks and regular maintenance, replacement and frequent drydock- installing TG100 seals, which reduced operational costs ing, the Thordon system results in threefold reduction in even further as there is less vessel down time and mainte- operational costs,” LeBoeuf explained.

nance. This means we are more attractive to our custom- Amelia Ray is powered by a pair of Mitsubishi S6R2 die- ers, more dependable and more reliable. We can better sel engines from Laborde Products. The engines, which de- plan drydock schedules in line with the operational needs liver 1,600 total horsepower at 1,400 revolutions per min- of our customers.” ute, drive Kahlenberg screws through Twin Disc MGX5321

October 2020 44 MN

43

43

45

45