Insulated Wire Expands

Insulated Wire (IW) announced the expansion of its capabilities to produce custom composite cables featuring low smoke/zero halogen polyurethane jackets. The company hasseen sales of these cables grow significantly – particularly in naval applications, both on submarine and surface vessels.

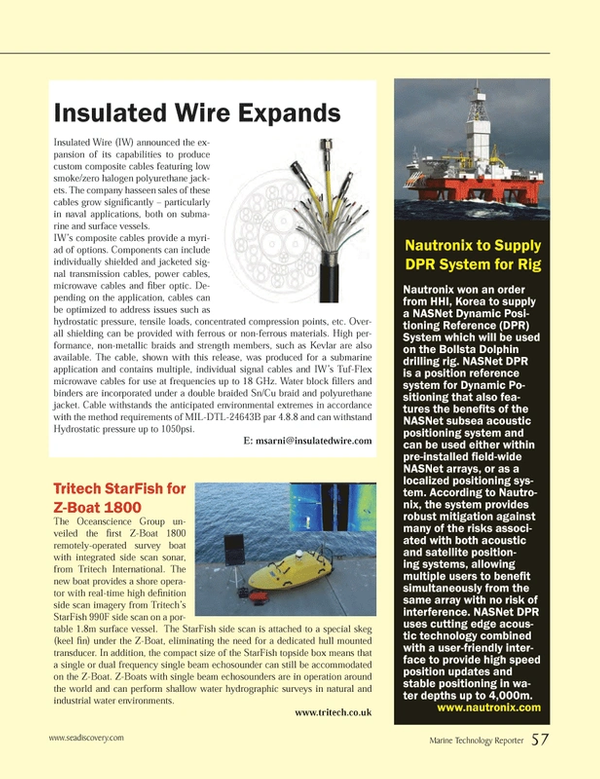

IW’s composite cables provide a myriad of options. Components can include individually shielded and jacketed signal transmission cables, power cables, microwave cables and fiber optic. Depending on the application, cables can be optimized to address issues such as hydrostatic pressure, tensile loads, concentrated compression points, etc. Overall shielding can be provided with ferrous or non-ferrous materials. High performance, non-metallic braids and strength members, such as Kevlar are also available. The cable, shown with this release, was produced for a submarine application and contains multiple, individual signal cables and IW’s Tuf-Flex microwave cables for use at frequencies up to 18 GHz. Water block fillers and binders are incorporated under a double braided Sn/Cu braid and polyurethane jacket. Cable withstands the anticipated environmental extremes in accordance with the method requirements of MIL-DTL-24643B par 4.8.8 and can withstand Hydrostatic pressure up to 1050psi.

E: [email protected]

(As published in the April 2014 edition of Marine Technology Reporter - http://www.marinetechnologynews.com/Magazine)

Read Insulated Wire Expands in Pdf, Flash or Html5 edition of April 2014 Marine Technology

Other stories from April 2014 issue

Content

- MTR April 2014: Editor's Note page: 6

- Predator II ROV Put through its Paces @ FAU page: 8

- Imenco & High Resolution Subsea Digital Imaging page: 10

- Robotic Marine Vehicles: Meet the Anaconda-2 page: 16

- Upgraded Alvin Sub Passes Scientific Sea Trials page: 20

- STEM: SeaPerch Underwater Robotic Championships page: 24

- Subsea Processing Boosting and Gas Compression page: 28

- Offshore Oil & Gas: Brazil’s Northern Frontier page: 34

- The Future of Arctic Drilling: 90 Billion Barrels & Counting page: 38

- Underwater Laser Scanning for Subsea Pipeline Inspection page: 42

- Wave-Propelled Vessel Debuts page: 50

- Buoy Range Added to the EIVA page: 51

- New Acoustic Release from Teledyne Benthos page: 52

- Sonardyne Debuts SensorView Software page: 52

- Teledyne TSS Launches AHRS and INS Systems page: 53

- New Gyrocompass from Kongsberg page: 53

- FSI Announces new LF Bubble Gun page: 54

- TWR Delivers 6 Slocum Turbulence Gliders page: 54

- Kongsberg Makes Multiple Debuts in London at Oceanology 2014 page: 55

- Product Spotlight: FLEXUS More than an ROTV page: 56

- Insulated Wire Expands page: 57

- Tritech StarFish for Z-Boat 1800 page: 57

- Nautronix to Supply DPR System for Rig page: 57

- Lankhorst Mooring Ropes for Western Isles Development FPSO page: 58

- Seacon Expands Connector Range page: 58

- iXBlue, Septentrio Create ATLANS-C page: 58

- EdgeTech System for Polish Defense AUVs page: 59

- HYPACK Automatic Download of ENC Charts page: 59