Rayotek: Seeing Under Pressure

Rayotek & Safer Viewing of Hostile Marine Environs

According to Bill Raggio, Rayotek Scientific isn’t specifically a maritime company, but it definitely is part of San Diego’s “Blue Economy.” “We’re both an engineering company and a sapphire and glass manufacturer. We makes specialized glass for windows and sight windows, diffusers, pressure vessels, hydraulics and boiler systems, submarine periscopes and camera covers,” says Raggio, Rayotek’s chief technology officer.

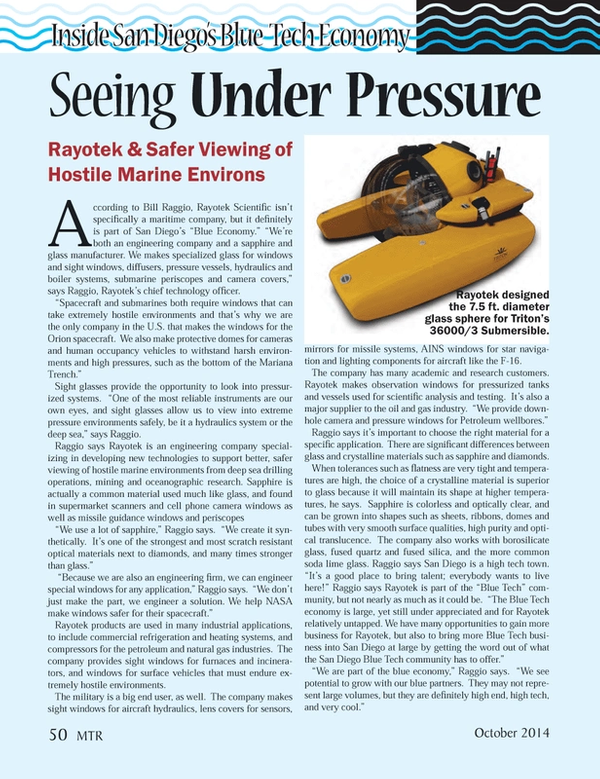

“Spacecraft and submarines both require windows that can take extremely hostile environments and that’s why we are the only company in the U.S. that makes the windows for the Orion spacecraft. We also make protective domes for cameras and human occupancy vehicles to withstand harsh environments and high pressures, such as the bottom of the Mariana Trench.”

Sight glasses provide the opportunity to look into pressurized systems. “One of the most reliable instruments are our own eyes, and sight glasses allow us to view into extreme pressure environments safely, be it a hydraulics system or the deep sea,” says Raggio.

Raggio says Rayotek is an engineering company specializing in developing new technologies to support better, safer viewing of hostile marine environments from deep sea drilling operations, mining and oceanographic research. Sapphire is actually a common material used much like glass, and found in supermarket scanners and cell phone camera windows as well as missile guidance windows and periscopes

“We use a lot of sapphire,” Raggio says. “We create it synthetically. It’s one of the strongest and most scratch resistant optical materials next to diamonds, and many times stronger than glass.”

“Because we are also an engineering firm, we can engineer special windows for any application,” Raggio says. “We don’t just make the part, we engineer a solution. We help NASA make windows safer for their spacecraft.”

Rayotek products are used in many industrial applications, to include commercial refrigeration and heating systems, and compressors for the petroleum and natural gas industries. The company provides sight windows for furnaces and incinerators, and windows for surface vehicles that must endure extremely hostile environments.

The military is a big end user, as well. The company makes sight windows for aircraft hydraulics, lens covers for sensors, mirrors for missile systems, AINS windows for star navigation and lighting components for aircraft like the F-16.

The company has many academic and research customers. Rayotek makes observation windows for pressurized tanks and vessels used for scientific analysis and testing. It’s also a major supplier to the oil and gas industry. “We provide downhole camera and pressure windows for Petroleum wellbores.”

Raggio says it’s important to choose the right material for a specific application. There are significant differences between glass and crystalline materials such as sapphire and diamonds.

When tolerances such as flatness are very tight and temperatures are high, the choice of a crystalline material is superior to glass because it will maintain its shape at higher temperatures, he says. Sapphire is colorless and optically clear, and can be grown into shapes such as sheets, ribbons, domes and tubes with very smooth surface qualities, high purity and optical translucence. The company also works with borosilicate glass, fused quartz and fused silica, and the more common soda lime glass. Raggio says San Diego is a high tech town. “It’s a good place to bring talent; everybody wants to live here!” Raggio says Rayotek is part of the “Blue Tech” community, but not nearly as much as it could be. “The Blue Tech economy is large, yet still under appreciated and for Rayotek relatively untapped. We have many opportunities to gain more business for Rayotek, but also to bring more Blue Tech business into San Diego at large by getting the word out of what the San Diego Blue Tech community has to offer.”

“We are part of the blue economy,” Raggio says. “We see potential to grow with our blue partners. They may not represent large volumes, but they are definitely high end, high tech, and very cool.”

(As published in the October 2014 edition of Marine Technology Reporter - http://www.marinetechnologynews.com/Magazine)

Read Rayotek: Seeing Under Pressure in Pdf, Flash or Html5 edition of October 2014 Marine Technology

Other stories from October 2014 issue

Content

- Hybrid-Powered Research Vessel Christened page: 16

- What's New in Floating Production Systems? page: 20

- The Road to Standardization page: 22

- Global Navy Power & Changing Paradigm of Submarine Programs page: 26

- Broadband Seismic for Enhanced Pre-salt Imaging page: 30

- Blue Tech Economic Engine Shifts into High Gear page: 40

- Greg Cox on San Diego's Blue Tech Cluster page: 42

- Scripps' San Diego Advantage page: 44

- Teledyne Impulse: Making Connections in San Diego page: 46

- Ocean Aero All About Ocean Observation page: 48

- Rayotek: Seeing Under Pressure page: 50

- SeaBotix: Mini-ROVs Sized Just Right for a Niche Market page: 51

- Xodus Subsea: New Era of Subsea Engineering Support page: 56

- Kongsberg Maritime 3D Monitoring page: 58

- Subsea Camera with Optical & Digital Zoom page: 58

- Woods Hole Selects Rapp CTD Winch page: 58

- Underwater Housing from Gates page: 58

- Bowtech Lamp Range Extended page: 59

- Hydro-Lek Manipulators on Italian Navy ROV page: 59

- Contact Rationalizing and Map Corrections Software page: 59

- SBG Miniature Inertial Sensors page: 59