SeaBotix: Mini-ROVs Sized Just Right for a Niche Market

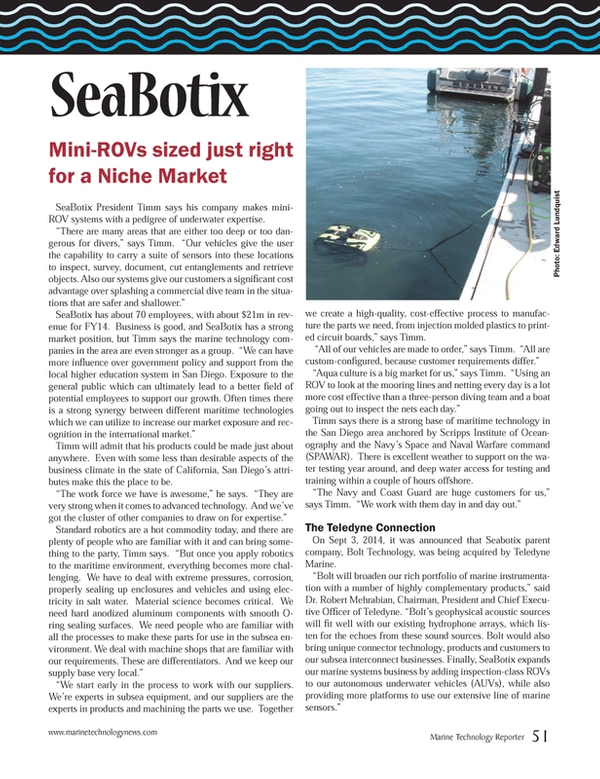

SeaBotix President Timm says his company makes mini-ROV systems with a pedigree of underwater expertise.

“There are many areas that are either too deep or too dangerous for divers,” says Timm. “Our vehicles give the user the capability to carry a suite of sensors into these locations to inspect, survey, document, cut entanglements and retrieve objects. Also our systems give our customers a significant cost advantage over splashing a commercial dive team in the situations that are safer and shallower.”

SeaBotix has about 70 employees, with about $21m in revenue for FY14. Business is good, and SeaBotix has a strong market position, but Timm says the marine technology companies in the area are even stronger as a group. “We can have more influence over government policy and support from the local higher education system in San Diego. Exposure to the general public which can ultimately lead to a better field of potential employees to support our growth. Often times there is a strong synergy between different maritime technologies which we can utilize to increase our market exposure and recognition in the international market.”

Timm will admit that his products could be made just about anywhere. Even with some less than desirable aspects of the business climate in the state of California, San Diego’s attributes make this the place to be.

“The work force we have is awesome,” he says. “They are very strong when it comes to advanced technology. And we’ve got the cluster of other companies to draw on for expertise.”

Standard robotics are a hot commodity today, and there are plenty of people who are familiar with it and can bring something to the party, Timm says. “But once you apply robotics to the maritime environment, everything becomes more challenging. We have to deal with extreme pressures, corrosion, properly sealing up enclosures and vehicles and using electricity in salt water. Material science becomes critical. We need hard anodized aluminum components with smooth O-ring sealing surfaces. We need people who are familiar with all the processes to make these parts for use in the subsea environment. We deal with machine shops that are familiar with our requirements. These are differentiators. And we keep our supply base very local.”

“We start early in the process to work with our suppliers. We’re experts in subsea equipment, and our suppliers are the experts in products and machining the parts we use. Together we create a high-quality, cost-effective process to manufacture the parts we need, from injection molded plastics to printed circuit boards,” says Timm.

“All of our vehicles are made to order,” says Timm. “All are custom-configured, because customer requirements differ.”

“Aqua culture is a big market for us,” says Timm. “Using an ROV to look at the mooring lines and netting every day is a lot more cost effective than a three-person diving team and a boat going out to inspect the nets each day.”

Timm says there is a strong base of maritime technology in the San Diego area anchored by Scripps Institute of Oceanography and the Navy’s Space and Naval Warfare command (SPAWAR). There is excellent weather to support on the water testing year around, and deep water access for testing and training within a couple of hours offshore.

“The Navy and Coast Guard are huge customers for us,” says Timm. “We work with them day in and day out.”

The Teledyne Connection

On Sept 3, 2014, it was announced that Seabotix parent company, Bolt Technology, was being acquired by Teledyne Marine.

“Bolt will broaden our rich portfolio of marine instrumentation with a number of highly complementary products,” said Dr. Robert Mehrabian, Chairman, President and Chief Executive Officer of Teledyne. “Bolt’s geophysical acoustic sources will fit well with our existing hydrophone arrays, which listen for the echoes from these sound sources. Bolt would also bring unique connector technology, products and customers to our subsea interconnect businesses. Finally, SeaBotix expands our marine systems business by adding inspection-class ROVs to our autonomous underwater vehicles (AUVs), while also providing more platforms to use our extensive line of marine sensors.”

(As published in the October 2014 edition of Marine Technology Reporter - http://www.marinetechnologynews.com/Magazine)

Read SeaBotix: Mini-ROVs Sized Just Right for a Niche Market in Pdf, Flash or Html5 edition of October 2014 Marine Technology

Other stories from October 2014 issue

Content

- Hybrid-Powered Research Vessel Christened page: 16

- What's New in Floating Production Systems? page: 20

- The Road to Standardization page: 22

- Global Navy Power & Changing Paradigm of Submarine Programs page: 26

- Broadband Seismic for Enhanced Pre-salt Imaging page: 30

- Blue Tech Economic Engine Shifts into High Gear page: 40

- Greg Cox on San Diego's Blue Tech Cluster page: 42

- Scripps' San Diego Advantage page: 44

- Teledyne Impulse: Making Connections in San Diego page: 46

- Ocean Aero All About Ocean Observation page: 48

- Rayotek: Seeing Under Pressure page: 50

- SeaBotix: Mini-ROVs Sized Just Right for a Niche Market page: 51

- Xodus Subsea: New Era of Subsea Engineering Support page: 56

- Kongsberg Maritime 3D Monitoring page: 58

- Subsea Camera with Optical & Digital Zoom page: 58

- Woods Hole Selects Rapp CTD Winch page: 58

- Underwater Housing from Gates page: 58

- Bowtech Lamp Range Extended page: 59

- Hydro-Lek Manipulators on Italian Navy ROV page: 59

- Contact Rationalizing and Map Corrections Software page: 59

- SBG Miniature Inertial Sensors page: 59