Subsea Technology and the New Routes to Residency

Efforts to increase remote capability often go hand in hand with increasing ROV residency. But exactly what form residency takes is diverging. Elaine Maslin takes a look.

Dial back the clock five years and there was a movement towards an idea dubbed subsea resident remotely operated vehicles (ROVs). The idea, in simple terms, is that you increase ROV availability and reduce cost and carbon emissions by having the vehicle permanently based subsea in underwater garages. A number of vehicles could even cover a cluster of fields, potentially with different owners who can dial up, on demand, a vehicle when they need it.

The resident ROV wasn’t an entirely new idea and there is still momentum behind the concept. But there’s also fragmentation; different approaches and concepts and even alternative routes to providing remote ROV services without the need for a fully crewed vessel.

Subsea 7’s tetherless autonomous intervention vehicle (AIV) has demonstrated its autonomous behaviours for inspection work offshore Norway and in the US Gulf of Mexico. In August, Norway’s IKM Subsea reached a 100-day continuous subsea operations milestone with its tethered Merlin UCV R-ROV at the Snorre B facility offshore Norway, where it’s been based since 2018, along with a tool stand, supported by on and offshore staff.

Oceaneering has been supplying ROV services through its E-ROV – an electric ROV deployed in a cage with batteries from which it can work for weeks at a time wherever it’s been put – while its Freedom ROV (more of a hybrid AUV/ROV) was expected to start untethered offshore trials in August with operations focusing on pipeline inspection starting in Q4.

Other ongoing projects include Italy’s Saipem and Norway’s Eelume working on systems able to work from a universal docking station, built by Blue Logic in Norway, with support from Equinor. For Saipem, that means its Hydrone-R vehicle, which is set due to be deployed at Equinor’s Norne field in the Norwegian Sea. Eelume, meanwhile, is targeting TRL5 by the end of 2021 for its snake-robot, culminating in two of them being deployed with a docking station at the Åsgard field offshore Norway in Q4 2021 for pipeline inspection, near template visual inspection and valve operation. Other concepts have also been covered in these pages, including Houston Mechatronic’s shape-shifting robot and Modus Seabed Intervention’s AUV system, as have moves to deploy ROVs from USVs.

TechnipFMC’s new Gemini ROV is already working in the US Gulf of Mexico for Shell. It comes with new manipulator interfaces and an onboard tool carousel. Images from TechnipFMC.

TechnipFMC’s new Gemini ROV is already working in the US Gulf of Mexico for Shell. It comes with new manipulator interfaces and an onboard tool carousel. Images from TechnipFMC.

-Shorter stays, more capability

Part of the reason for this fragmentation is due to the range of operations ROVs can perform, from inspection to heavy duty intervention and a lack of definition of what a resident system needs to be, how long it needs to remain subsea and when remote operations is remote operations, says Peter MacInnes, marketing director, ROV services, at TechnipFMC, which has recently unveiled its new Gemini ROV, two of which are already working in the US Gulf of Mexico from two deep-water rigs. Most of what has been done to date, in terms of residency, has been at the observation end of the scale, he says.

With Gemini, TechnipFMC is targeting the heavy intervention end of the scale, for work on BOPs and subsea trees, for example, including fluid intervention, which is why it’s a hydraulic ROV and not fully electric, says MacInnes. For this type of work, it’s not about the length of deployment, it’s about what it can do while it’s there, he says. That’s why Gemini has been designed for month-long deployments, with some significant advances around tooling and automation (as well as having two manipulators as standard).

-An ROV with a tool belt

In terms of tooling, Gemini comes with an inbuilt tooling carousel, with 15 tools, and a further 15 on the tether management system. These have a new interface; instead of the traditional manipulator jaws that grab a T-bar on a tool, the manipulator tip is a stab that picks up a tool and provides a hydraulic, electric and communications interface. The vehicle also has up to five machine vision cameras, so the vehicle knows what it’s looking at and can more accurately measure distance; the machine vision cameras help fine-tune station keeping capability to within 25mm (better than what can be achieved with current navigation sensors, MacInnes says). Together, these capabilities enable the vehicle to perform predetermined tasks, such as tool selection, helping to overcome any issues with latency. The pilot (remote or otherwise) simply taps a touch screen to select the tool (an “intent based instruction”) and the ROV does the rest – instead of having to bring the ROV to surface to reconfigure the tooling, says MacInnes.

These capabilities take it a step closer towards operating under a level of supervised autonomy. And it means there’s more consistency in the performance of these tasks (it could take anywhere between 10 minutes to two hours to insert a hot stab, depending on experience, with the current generation ROVs, says MacInnes).

“It’s the similar technology to companies such as Tesla but more complex,” he says, “because, for a car, all it has to do is avoid hitting something.

As long as it avoids being within 2-3cm, it’s done its task. We need to physically engage with things, such as insert a hot stab, and that creates additional complexity.”

The move towards supervised autonomy will support a reduction in the amount of support required offshore, including ROV crew, says MacInnes. But whether full autonomy is needed – and if it could justify the investment that would be required – is questionable, he says. One thing that is viable, with the level of supervised autonomy that TechnipFMC is moving towards, is operating these systems from a USV, he says. “With supervised autonomy, we can start to interface this new generation of work class ROV technology with new generation of USVs,” says MacInnes. “It’s achievable and we are on a path to achieving that.”

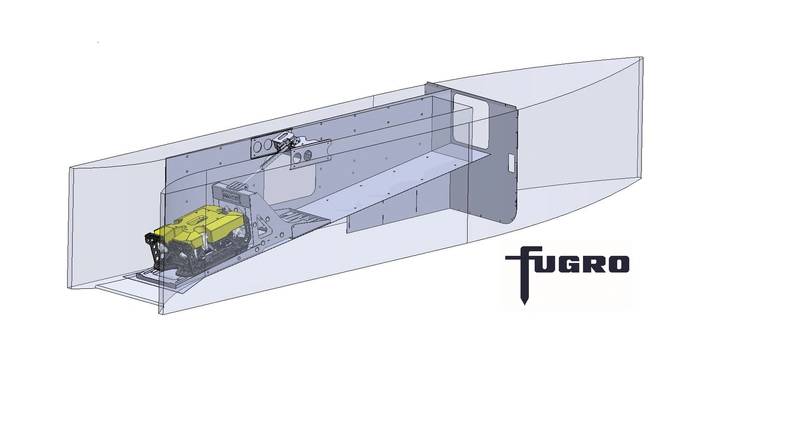

Fugro’s new eROVs (Fugro Blue Volta) will be deployed from its 12m-long “Fugro Blue Essence” vessels being built by SEA-KIT.

Fugro’s new eROVs (Fugro Blue Volta) will be deployed from its 12m-long “Fugro Blue Essence” vessels being built by SEA-KIT.

Image from Fugro.

-On-board remote residency

Operating an ROV from a USV is on the target list for Fugro. It says that, by the end of this year, it will be the first company in the world to provide offshore subsea inspections via USVs and ROVs that are operated from onshore Remote Operations Centres (ROCs); including ROVs and autonomous underwater vehicles (AUVs) deployed from USVs.

Being able to use a remotely operated USV, ROV inspection solution to cover, according to Fugro, potentially 75% of today’s inspection scope has the obvious safety, efficiency and sustainability benefits. It could also enable operations within the 500 m exclusion zone, due to the lower threat posed by a 12-tonne vessel compared with a full size ROV support vessel, says Ivar de Josselin de Jong, Global Director for Remote Inspection, Fugro.

The firm has a strategic partnership with USV builder SEA-KIT, from whom it has ordered its first two 12m vessels; one due to enter operations in Australia by the year end and the other coming into the North Sea early next year. The 12 m “Fugro Blue Essence” vessels will host a new “Fugro Blue Volta” high-power inspection eROV (electric ROV) able to do inspection work down to 450 m, says de Jong. In addition, a 24 m vessel is being designed, targeting 2,500 m depth deployment with a new “mid-range” eROV able to perform intervention work. The new hydrodynamically designed eROVs have been designed and developed by Fugro and the first two units are being built in their ROV factory in Singapore, with deliverydue in October.

Fugro has Remote Operation Centres from which to operate its ROVs and USVs. Photos from Fugro.

Fugro has Remote Operation Centres from which to operate its ROVs and USVs. Photos from Fugro.

-Delivering ROVs with USVs

As part of its new fully electric eROV design, Fugro is moving navigational intelligence to the vehicle to facilitate more efficient piloting and to prepare for future tetherless operations. Increasing the level of autonomy will aid vehicle control when deployed from an USV, with the USV acting as a surface gateway, when needed. Alternative scenarios could involve a development that enables the upload of a mission and let it execute the task, says de Jong. This could potentially support field resident scenarios with the USV acting as a taxi for an ROV. The company is also paying close attention to developments in electric tooling.

“It’s an important change and transformation, the ROV business is going through,” de Jong says. But it’s not without its challenges. “The big challenge with ROVs is that they need so much attention day to day. Field resident or USV based ROVs need to be left alone,” says de Jong. “We’re aiming at 30 days continuous ROV operations from the Fugro Blue Essence, remotely controlled from one of our ROCs. Compared to the current situation that’s unimaginable. Changing from an 80 m ROV support vessel with 60-70 people on board moving to a situation where they are onshore.”

-Bandwidth, regulatory and HR challenges

The transition to remote and autonomous operations also brings connectivity challenges, he adds, Fugro’s ROCs are equipped to facilitate the required bandwidth, uptime and reliability of the satellite connection, which is key to safe operations and effective data delivery To enable smooth operations upon delivery of the first systems, Fugro has taken up a front running role in developing the legal and operational framework, maritime regulations, etc. They are working together with regulatory bodies and flag states to jointly work on a guideline for uncrewed offshore operations, he adds.

It’s also going to be a human resources challenge. “It’s a super exciting environment and it’s extremely interesting to be involved in these developments and at the forefront of this massive transformation,” says de Jong. It’s a transformation that is going to change the way people work, change the type of assets used and the legislative environment we operate in. “We won’t have client representatives onboard because we won’t have anyone onboard,” says de Jong. “We have a remote client solution where clients from any location around the world, enter chat rooms, look at real time data acquisition and back deck CCTV that ties into the ROCs.”

-Power to the resident subsea robot

Meanwhile, others have been focusing on subsea power for underwater vehicles. Independent North Sea operator Chrysaor, for example, is working with wave energy firm Mocean Energy, subsea energy storage company EC-OG and AUV specialist Modus in a project to look at using renewable energy to supply subsea power for resident AUVs or subsea tiebacks. The project, supported by the Oil and Gas Technology Centre, will look to use Mocean Energy’s Blue Star wave energy converter and EC-OG’s HALO subsea energy storage system.

New Jersey based Ocean Power Technologies have launched a lithium-iron phosphate based Subsea battery system with a nominal storage capacity of 132 kilowatt-hours. It utilizes OPT’s battery management system, can be scaled up, for higher power demand, and can be integrated with the firm’s PowerBuoy wave energy convertor for recharging or used standalone.

What’s clear is that all roads point towards increasing remote capability, which requires a level of automation, and ultimately towards autonomy. But opinions over the shape and form these systems take is, depending on their use, differ.

IKM Subsea has notched up 100 days continuous operations at Snorre B with its Merlin UCV R-ROV. Photo from IKM Subsea.

IKM Subsea has notched up 100 days continuous operations at Snorre B with its Merlin UCV R-ROV. Photo from IKM Subsea.

Eelume and Kongsberg Maritime have also formed a collaborative partnership with Triumph Subsea Services to support its and its underwater garage development. The partnership is focusing on 500m and then 1500m and 4000m systems, including a docking system that will allow Eelume to be deployed with ROVs and subsea packages to create an integrated autonomous subsea inspection and light intervention robotic system for easy launch from a vessel. Triumph will also fit two Eelume vehicles with residency garages onto all its construction vessels, including wind turbine installation vessels.

Read Subsea Technology and the New Routes to Residency in Pdf, Flash or Html5 edition of July 2020 Marine Technology

Other stories from July 2020 issue

Content

- Underwater Vehicle Propulsion Tech: Tail Shape and Vehicle-Propulsor Performance page: 16

- Charting Terradepth's Big Ambitions in the Unmanned Vehicle Space page: 20

- Interview: RDML Gallaudet Steers NOAA’s Path Toward Uncrewed Maritime Systems page: 26

- Subsea Technology and the New Routes to Residency page: 38

- Hacking 4 Environment: Oceans - Creating Entrepreneurs from Scientists and Students page: 46

- Tracking Climate Change onboard SeaExplorer page: 50