Exxon Begins Operating Remote Sea-Floor Production System

A full-scale production pilot test of a prototype subsea system designed to produce oil and gas from remotely controlled ocean-floor equipment is underway in the Gulf of Mexico, according to Exxon USA.

"This is the first time that oil has been produced through a well and sea-floor production system that were remotely installed, remotely completed, remotely operated, and remotely maintained, by the use of deepwater diverless techniques," said A.C. Garner Jr., manager of Exxon's southeastern production division in New Orleans, La.

Exxon's prototype Submerged Production System (SPS) is located 27 miles southeast of Grand Isle, La., in 170 feet of water.

The system was brought on production using equipment and diverless procedures suitable for producing oil and gas in water 2,000 feet deep, according to Mr.

Garner.

"In the United S t a t e s , the search for new reserves of oil and gas offshore is rapidly approaching water depths of 2,000 feet," he explained. "Overseas, Exxon has drilled exploratory wells in 3,400 feet of water. Development of offshore reserves by conventional fixed platforms will be limited by costs to water depths of about 1,000 feet. The objective of our Submerged Production System project is to develop and demonstrate a diverless system capable of producing oil and gas in water depths beyond 2,000 feet. Bringing the prototype Submerged Production System on production is a major step towards accomplishing that goal." Exxon expects the pilot production test to last about a year.

"By the time the production test is completed, Exxon will have invested more than $66 million and over 400 man years of engineering effort to develop the technology and know-how to produce oil and gas from the deep waters of the world," Mr. Garner said.

The SPS project began in 1968, when Exxon r e a l i z e d t h a t the search for petroleum would extend beyond the capability of conventional offshore production technology in the near future. After successful onshore tank tests, a full-scale offshore test of the system was initiated, and construction began in June 1973. The SPS sea-floor structure, called a template, was launched in October 1974 and was secured to the sea floor through the use of diverless, deepwater procedures. Remotely controlled equipment and pro- cedures were developed to lay and connect five pipelines and two power and control cables to the template. Every component of the system was subjected to extensive testing. Initial production was achieved on February 11, 1977.

Oil can flow from the well, through a sub s e a production manifold, through a separator and pump station, and through a pipeline to a nearby production platform. Throughout the production sequence, sensors monitor the flow of oil. Should abnormal conditions develop, the on-bottom safety control system will automatically shut in the affected part of the system. A remote control system provides the command and power link between a surface control center and the remotely operated equipment on the ocean floor. The remote control system, in conjunction with the safety alarm and shut-in system, is designed to provide fail-safe operation of the Submerged Production System. Inverted pans over oil-producing equipment provide a maximum of pollution control in the event of an oil leak.

A key to the system is a maintenance manipulator. When needed, the manipulator is taken to the location and used by remote control to perform routine maintenance operations by replacement of equipment on the Submerged Production System.

The manipulator is launched from a workboat and descends to the template, where it moves along a track around the unit. A system of u n d e r w a t e r television cameras built into the manipulator allows the operator on the surface to watch and control the movements of the manipulator.

Since the SPS was launched offshore, the manipulator has been to the sea floor more than 30 times and has successfully performed the basic types of equipment i n s t a l l a t i o n and maintenance operations.

The Submerged Production System project will enter its final phase in late summer when Exxon plans to install, connect and operate a special production riser designed to test an alternate surface connection for operation of the subsea system and for receiving production from the ocean floor.

During the coming year, the company will conduct extensive performance and reliability tests of all Submerged Production System components. An additional well will be brought on production to increase the flow rates through the unit. "By the time commercial reserves of oil and gas are discovered beneath the deep waters of the world's oceans, Exxon wants to be ready to design a Submerged Production System to develop such reserves as safely, rapidly, and economically as possible," said Mr. Garner.

Read Exxon Begins Operating Remote Sea-Floor Production System in Pdf, Flash or Html5 edition of September 1977 Maritime Reporter

Other stories from September 1977 issue

Content

- Lloyd's To Class Two Large Crane Barges To Be Built By Mitsui page: 4

- Estimated Foreign Cost Of Two LNG Carriers $115.5 Million Each page: 6

- McAllister Brothers Name Robert Lounsbery Chief Operating Officer page: 7

- Lockheed Wins Contract To Evaluate Ocean Platform Candidates page: 7

- Bethlehem Steel Names G.Y. Marriner Manager San Francisco Yard page: 7

- AMPAC To Build Four Container Feeder Ships At Cost Of $92 Million page: 7

- MarAd Approves Title XI For Five Moran Tugboats page: 8

- SNAME New York Section Announces Program For 1977/1978 Season page: 8

- Willamette Awarded $15 Million To Modernize Alaska State Ferry page: 9

- Marathon Manufacturing Adds $61 Million To Drilling Rig Backlog page: 9

- NASSCO Building 188,500-DWT Tankers For Alaskan Oil Trade page: 10

- Exxon Begins Operating Remote Sea-Floor Production System page: 10

- Propeller Club Convention Includes Shipyard Panel page: 11

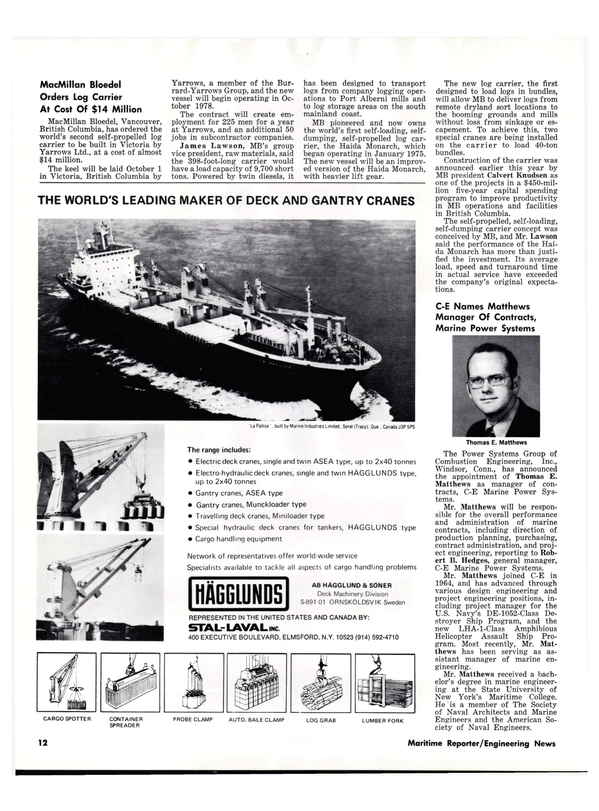

- MacMillctn Bloedel Orders Log Carrier At Cost Of $14 Million page: 12

- C-E Names Matthews Manager Of Contracts, Marine Power Systems page: 12

- Role Of Ro/Ro Shipping In Dry Cargo Trade page: 12

- Port Of New Orleans Presents Key To City To Egyptian Official page: 13

- Representatives Meet For First Time In Bahrain page: 14

- Marystown Shipyard Reports On Progress Of $23-Million Norwegian Tugboat Contract page: 14

- Dravo Awarded Two Contracts Totaling $7 Million page: 14

- Morris Guralnick Associates, Inc. Name Hubert E. Russell page: 14

- Canada's Newest Great Lakes Bulk Carrier Launched page: 16

- Todd Seattle Division Lays Keel For Royal Australian Navy Frigate page: 18

- Title XI Approval For Two IOT Subsidiaries page: 18

- Jerry D. Icenhower Named President Glitsch Cryogenics page: 18

- Hillman-Designed New Class Towboat Delivered To Exxon At Baton Rouge page: 19

- BP Invests $50 Million In Stolt-Nielsen page: 20

- Speakers Named For Weather Conference September 14-15-16 page: 22

- $45-Million Subsidy Repayment Approved page: 23

- Study Shows Worldwide LNG Production Increase —60 Carriers Needed page: 24

- Bethlehem Steel Subsidiaries Name Collins And Coulahan page: 25

- Gotaverken Converts Cargo Ship To Carry 32,000 Live Sheep page: 25

- Halter Marine Delivers Large Supply Boat To George Engine Co. page: 26

- Bethlehem Steel Shipbuilding Names Roland V. Danielson —Hollinshead De Luce Retires page: 26

- Perspectives On Third World Port Development page: 30

- APL Names Hubbard Senior VP Operations page: 31

- New National Supply Anchoring Windlass page: 31

- Shallow Water Maneuvering Trials Completed In Gulf page: 32

- Farrell Sale And Leaseback Agreement Approved By MarAd page: 32

- Delta Steamship Names Badger And Collins page: 32

- Gross Tonnage In ABS Classification Exceeds 100-Million Mark page: 33

- Airfilco Appoints Kevin McPherson page: 33

- CCN Of Brazil Launches New Type Bulk Carrier page: 33

- 51st Annual Propeller Club Convention And 1977 American Merchant Marine Conference Set For Galveston, Texas, Oct. 10, 11, 12, 13 And 14 page: 34

- Bulletin Describes Heavy-Duty Oil Filtration Systems page: 35

- Eight-Page Brochure Describes National's Fully Hydraulic Cranes page: 35

- Joseph Hurley Named President ITT Decca Marine page: 36

- Oceangoing Split Hull Self-Propelled Dredge Completes Trials In Gulf page: 37

- ITT Decca Marine Introduces 'Clearscan' New Radar Technique To Reduce Interference page: 38

- Todd Shipyards Los Angeles Division Lays Keel For First Of Six U.S. Navy Frigates page: 38

- MacGregor Slewing Ramps Successfully Tested page: 39

- Skagit Corporation Announces European Dealership Agreement page: 40

- FMC Marine & Rail Lays Keel For Ro/Ro Barge To Carry 374 Forty-Foot Truck Trailers page: 40

- Egyptian Shipyard Receives License To Build Willard Boats page: 42

- Bergeron Industries Names Captain Tatman page: 42

- Port Authorities (AAPA) 66th Annual Convention Set For Mexico City page: 43

- Lloyd's Register Completely Revises Rules For Marine Refrigerated Cargo Installations page: 44

- Tanker Design Change Approved By MSB page: 44

- Navy Contracts For Additional Years Of MARISAT Satellite Service page: 46

- Mitsubishi Receives Tug Barge Systems' License To Build page: 46

- Petro-Marine Names Murray Burns Manager Process Engineering page: 47

- Norshipco Dedicates New $5-Million Repair Pier page: 47

- COMSAT General Expands MARISAT Services To Entire Indian Ocean page: 48

- U.S. Lines Names Three In Operations page: 48

- Fetzner Named President Sun Trading & Marine page: 48

- Philippine Center Exhibit Highlights Filipino Seaman page: 49

- Henschel Announces New Steering-Failure Alarm page: 49

- Tulsa Port Of Catoosa Sets Tonnage Record page: 49

- Jane's Fighting Ships 1977-78 Revised Edition page: 49

- Stanford Research Awarded $271,000 For Firefighting Study page: 50

- Gulf Oil Trading & Transportation Announces Management Changes page: 51

- Renegotiation Board Erred In Computing Lockheed Steel Usage page: 51

- Pott Industries Names Miller VP Offshore Marine Services Div. page: 54

- Joseph R. Burgess To Head Central Pacific Shipping Agency page: 56

- Capt. James F. McNulty New Dean At Maine Maritime Academy page: 56

- Richard Daschbach Named Federal Maritime Commission Chairman page: 57

- Keene Brochure Describes Marine Discharge Control System page: 57

- Heavy Weather Ship Operation Subject Of Webb Seminar page: 58