USCG Invests in Low Engine Exhaust Temps

Confronted with high exhaust temperatures and emissions on the Alco engines of its Polar Class icebreakers, the U.S. Coast Guard turned to ABB for a solution.

The answer was quickly found: In a similar case the year before, retrofitting a tug's engines with ABB turbochargers had reduced the exhaust temperatures by 20 percent.

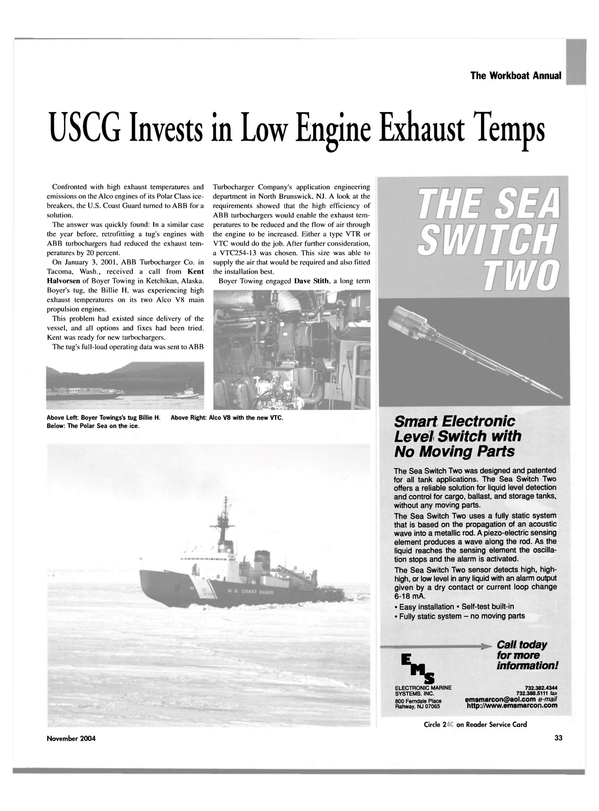

On January 3, 2001, ABB Turbocharger Co. in Tacoma, Wash., received a call from Kent Halvorsen of Boyer Towing in Ketchikan, Alaska.

Boyer's tug, the Billie H, was experiencing high exhaust temperatures on its two Alco V8 main propulsion engines.

This problem had existed since delivery of the vessel, and all options and fixes had been tried.

Kent was ready for new turbochargers.

The tug's full-load operating data was sent to ABB Turbocharger Company's application engineering department in North Brunswick, NJ. A look at the requirements showed that the high efficiency of ABB turbochargers would enable the exhaust temperatures to be reduced and the flow of air through the engine to be increased. Either a type VTR or VTC would do the job. After further consideration, a VTC254-13 was chosen. This size was able to supply the air that would be required and also fitted the installation best.

Boyer Towing engaged Dave Stith, a long term Skipper and Senior Port Engineer for the Company, to supervise the retrofit at the Fisherman's Terminal dry dock in Seattle. On June 1, 2001, the Billie H picked up a loaded barge from another tug and towed it at nine knots to check the results. They were excellent: Exhaust temperatures were down to well below 900 °F — a reduction of 20 percent. One week later the tug was back at work, towing freight barges between Seattle and Ketchikan.

The following year, in March, Lt. Don Miller with the Naval Engineering Support Unit of the Coast Guard in Seattle called ABB with the same problem: The USCG was experiencing high exhaust temperatures on the Alco V16 main propulsion engines and the Alco V8 SSDGs on its Polar Class icebreakers. ABB recounted the case of the Billie H and visits to the tug were arranged. Intrigued with the results, the Coast Guard invited ABB to bid replacement turbochargers on a one time trial basis.

ABB's offer was accepted and a VTC304 and VTC254 turbocharger were purchased for the V16 and V8 engine, respectively. The units were to be installed by NESU Seattle, with technical assistance provided by ABB. In September 2002 the original turbochargers were removed and the two ABB units were rigged into engine room no.2 on the USCG icebreaker Polar Sea.

Within two weeks both units had been installed and testing could commence.

Better Data The Coast Guard contracted the U.S. Navy's Fleet Technical Support Center, Atlantic (FTSCLANT) out of Norfolk, Va., to conduct the trials. The tests, which took place at the dock in Seattle, compared main engine I A, fitted with an original Alco turbocharger, with main engine 3A, which had been fitted with the ABB VTC 304 turbocharger. The Polar Sea's No. 2 SSDG with an original factory turbocharger was compared with No. 1 SSDG which had had the ABB VTC254 turbocharger fitted.

Am Rest-Air Quality, LLC, of Peston, Wash., set up the measuring equipment on the stacks. The results for all four engines were soon in, and they showed convincingly that the conversion had had the hoped-for effect.

The improvement in the V I 6 installation's emissions was especially impressive.

At full load the engine with the ABB VTC304 turbocharger reportedly emitted 5 percent fewer hydrocarbons, 15 percent less carbon dioxide and 40 percent less carbon monoxide, while visible smoke at the stack was down by 77 percent.

In its final report. Am Rest-Air Quality noted that the comparative results for the third load point of 2.1 MW were interesting. While CO emissions for the main engine with the ABB VTC304 turbocharger were, as expected, much lower (36 percent, or 180 ppm versus 280 ppm), the recorded NOx concentration was also lower for this engine (1.463 ppm for 3a versus 1,604 ppm for la). An examination of the trend data showed that while the NOx emissions from engine 1A continued to rise as the load was increased, in the case of engine 3A they actually fell as the engine approached the 2.1 MW load point, leveling off at around 1,500 ppm.

The 1A NOx concentration rose to approximately 1,630 ppm and leveled off at around 1,615 ppm. Comparison of the total hydrocarbon concentration showed a similar reduction (50.0 ppm for 3a versus 52.6 ppm for 1A). A marked difference in the opacity readings was also noted: While visible exhaust emissions for 1A increased to and remained at 35 percent at the 2.1 MW load point, those for the engine with the ABB turbocharger fell consistently to below 10 percent.

With the results of the dock trials documented, the Coast Guard now wanted to know how the retrofitted engines would perform in the warmer waters of the tropics.

To find out. Bill Sanowski of NESU and the FTSCLANT inspectors joined the Polar Sea in Honolulu, on its annual trip to Antarctica to break the ice into McMurdo Scientific Station during the southern hemisphere's summer.

Extensive tests were subsequently run on the same four engines between Hawaii and Australia.

Comparison of the data for the SSDG engines showed that, with the boost, rack and firing pressures approximately equal, exhaust temperatures for the engine with the new VTC254 turbocharger were down, on average, 150°F. Comparison of the main engines' performance showed that engine 3A fitted with an ABB turbocharger was running running at a higher load (2.4 MW compared with 2.33 MW for engine 1 A), the rack and firing pressures were down, and exhaust temperatures were a full 300°F lower. After the vessel returned from Antarctica in March 2003 the USGC made the decision to install ABB VTC254 turbochargers on the SSDG engines of all its Polar class icebreakers.

The ABB Turbocharger office in Tacoma was able to modify two SSDG engines aboard the Polar Sea and one SSDG on the Polar Star before these two vessels headed south that year for the Antarctica summer. This year (2004) ABB also supplied VTC304 turbochargers for the main engines on these ships, the remaining main engine turbochargers being scheduled for installation during routine repairs in 2005.

Circle 3 7 on Reader Service Card

Read USCG Invests in Low Engine Exhaust Temps in Pdf, Flash or Html5 edition of November 2004 Maritime Reporter

Other stories from November 2004 issue

Content

- Austal Launches 417 ft. Aluminum Ship page: 9

- Design Completed for Steamship Authority Ferry page: 9

- Blount to Deliver MV Isleno page: 10

- SF Bay Ferry Logs Impressive Performance page: 11

- NASSCO Holds Ceremony for Fourth BP Tanker page: 12

- K&C Wins $6M Navy Contract page: 12

- Air Emissions from Ships page: 14

- Shipboard Training Comes of Age page: 17

- Demystifying Parametric Roll page: 20

- A Bright Spot in Oil Patch Vessel Construction page: 26

- Senesco Marine Signs Contract For 140,000-Barrel DH ATB page: 30

- Coffee Company Investigates MContainer-on-BargeM Service page: 31

- USCG Invests in Low Engine Exhaust Temps page: 33

- Seacraft Delivers RV Hercules page: 36

- Caterpillar Gets "ACERT"-ive page: 37

- Making the Mark For Crescent Towing's Fleet page: 40

- The New Wartsila 46F page: 41

- Market Vision with Wartsila s Ole Johansson page: 42

- VT Halter Launches PCTC page: 44

- Aluminum Industry Continues Support for the Marine Market page: 46

- Film Celebrates Golden Age of NW Boats page: 47

- Pressure Transmitter Receives ABS Approval page: 48

- Fire Prevention: "Rising" to the Occasion page: 48

- For Those in Peril page: 50

- A Future in Composites page: 52

- Extra Value in Chinese Construction page: 53

- Record Spend on Propulsion? page: 54

- Collaboration Creates Vehicle for CNG Solutions page: 56

- Milestone Reference with MAN B&W page: 58

- The Will for Business page: 58

- Wider Remit for Dutch Matchmaker page: 58

- 2n d Generation Onboard NAPA Tanker Released page: 58

- Nichols Named "Maritime Man of the Year" page: 59

- ACBL Makes Appointments page: 59

- International Paint Japan K.K. - Open for Business page: 60

- European Yard Initiative - Will it Work? page: 62

- A.P. Meller-Maersk Creates Dedicated Tech Group page: 64

- SembCorp Signs Breakthrough, Long Term LNG Deal page: 66

- Keppel Batangas Completes SemiSub Repair page: 68

- A&P Tyne Re-Delivers FPSO Haewene Brim page: 68

- Crane Materials Launches TimberGuard page: 70

- Fincantieri Orders Water- Lubed Shaft Bearings page: 70

- Bilge Water Treatment Unit Approved By LR page: 71

- Electric Propulsion for Coastal Ships page: 72

- ALSTOM Wins $102M Navy Deal page: 73

- Offshore & Marine Chose Vacon AC Drives page: 73

- Successful Full Load Operation of 5-MW Ship Propulsion Motor page: 74

- Innovative Tweendeck Patented in U.S. page: 76

- MAN B&W Records Busy Hamburg Show page: 77

- Transas Demonstrates New Tech at SMM page: 77

- BV Launches Project Management Solution page: 78

- Xantic Offers New Web-Based Tool page: 79

- New AIS Targets U.S. Workboat Market page: 80

- Hepworth Makes a Good Show at SMM page: 80

- New PVC-Free Alternatives for Interior Decoration page: 80

- A High-End Global Satcom Presence page: 82

- IPS Marine Lands New Blue Chip Casino page: 85

- Rigdon Marine Promotes Harkness to CFO Post page: 85

- Tidewater: Effects of New Tax Bill Are Positive page: 86

- Bollinger to Design, Build Five DH Hot Oil Barges page: 87

- B+V Wins Passenger Ship Contract page: 88

- In Remembrance: Captain Fred Kosnac Jr. (1928-2004) page: 92

- Electronic Charting Aboard APL China page: 93

- Electric Boat Optimizes Nuclear Sub Repairs page: 94

- Kramek, Liu Snare Top SNAME Honors page: 97