Z-Drive Collaboration on the Inland Waterways Expands

By Joseph Keefe

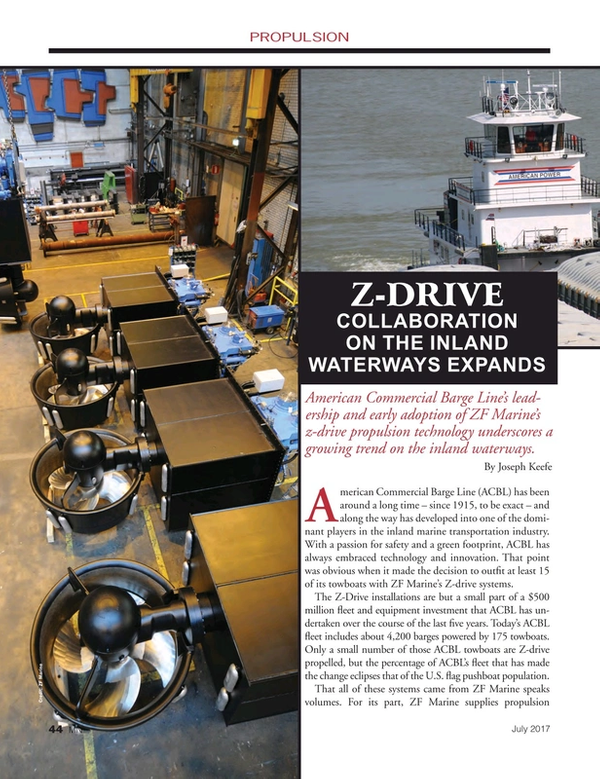

American Commercial Barge Line’s leadership and early adoption of ZF Marine’s z-drive propulsion technology underscores a growing trend on the inland waterways.

American Commercial Barge Line (ACBL) has been around a long time – since 1915, to be exact – and along the way has developed into one of the dominant players in the inland marine transportation industry. With a passion for safety and a green footprint, ACBL has always embraced technology and innovation. That point was obvious when it made the decision to outfit at least 15 of its towboats with ZF Marine’s Z-drive systems.

The Z-Drive installations are but a small part of a $500 million fleet and equipment investment that ACBL has undertaken over the course of the last five years. Today’s ACBL fleet includes about 4,200 barges powered by 175 towboats. Only a small number of those ACBL towboats are Z-drive propelled, but the percentage of ACBL’s fleet that has made the change eclipses that of the U.S. flag pushboat population.

That all of these systems came from ZF Marine speaks volumes. For its part, ZF Marine supplies propulsion system components for a myriad of military and commercial vessels and workboats, in a power range from 10 to 14,000 kW. The product portfolio includes a comprehensive range of transmissions, propellers POD-drive systems, steering systems and CANbus-compatible, electronic control systems, azimuth thrusters, tunnel thrusters, bow thrusters and sail drives.

As ZF penetrates deeper into z-drives for brown water, early adopters have found performance gains, increased maneuverability, and reduced fuel consumption with this technology. With over 150 Z-drive units already delivered on the inland waterways alone – the first to Southern Towing back in 2009 – the ZF thruster equipped fleet has well over 1 million operating hours, and counting. Nevertheless, says ZF Marine’s Marketing and Communications Manager Martin Meissner, “ZF is not content to sit on its hands, annually investing about 5 percent of its sales in research and development.”

The ABCs of ACBL’s Early Adoption

In a white paper released in 2014 by The Shearer Group, Ed Shearer and Greg Beers described the next generation of inland vessels, what will drive design changes and the advantages of azimuthing stern drives – or ‘Z-Drives,’ for short. The authors pointed out that towboats on all the inland waterways and Gulf Coast have traditionally been built using main engines connected to reduction gearboxes connected to long drive shafts passing through the towboat hull.

The Shearer Group touts the advantages of using z-Drives on inland towboats, including decreased installation time, increased fuel efficiency, increased trip time efficiency, decreased maintenance downtime, and higher customer satisfaction. In fact, savings in fuel and trip time from ten to thirty percent have been shown to be possible – in theory and actual towboat operation.

According to Bill Foster, ACBL’s Senior Director of Engineering, the ACBL fleet currently boasts 13 Z-drive boats and two more are on the way (newbuild). And, he told Marine News in June, ACBL had two primary reasons to go with the Z-drives. “Our two primary reasons centered on safety – specifically to achieve improved handling to reduce operational risk. Also at the top of that list was fuel economy,” he said, adding, “Our expectations for reliability are the same for both Conventional and Z-Drive boats.”

Regarding performance, Foster says, “Our experience has been that the boats save fuel compared to conventional propeller/rudder designs (savings 10-20 percent depending on the service the boats are in).” He continued, “We have one boat in dedicated fleet service and have a recognized productivity enhancement, and improved operational safety. Currently we are at about 10 percent with Z-drives, and depending on the service and our continued positive experience with Z-drives this is very likely to continue to grow in the coming years.”

Z-Drives: stirring up that brown water

Two Z-Drive tugs can theoretically take the place of four conventional tugs during the typical ship docking operation. But, how does that ‘power metric’ translate to inland pushboat operations? We asked Foster in June and he explained, “We expect that four to five Z-drive fleet boats will replace six conventional fleet boats, but in the mainline and dedicated boat trades, the value proposition will be more returned do to the improved handling, and reduced fuel consumption, a like HP Z-drive or conventional towboat is still a requirement.” Foster then asked a question of his own, saying “The big question is what size of a large HP Z-drive boat would be needed displace the large 9,000-11,000HP lower Mississippi boat, and can it balance the need for large tows Northbound and southbound in the open river.”

Separately, some owners who adopted the Z-Drive solution found operational efficiencies that allow them to install up to 20 percent less power with steerable thrusters versus traditional FPP props. For ACBL, Foster reports, “In our experience we have found a few applications where this is possible, but it is still not an accepted practice in the market that the bulk of our Z-drive boats are trading in.”

Looking Ahead

According to Foster, to date, ACBL has only built (ZF-powered) boats in one Horsepower/size segment of the fleet. As to when that might change, he said, “There are six other HP classes that we have only conventional drive. The cost to build new; and our ability to extend the life of the existing assets will slow the expansion into other areas.” And while some stakeholders say that Z-Drive propulsion will soon overtake conventional drive methods on the U.S inland rivers, Foster hedged his bets when asked for his assessment. Even as an early adopter with encouraging results to start, he cautioned, “It is possible, but it will take many years before it is widely accepted as the standard. The immense infrastructure of spare parts, and set up of the support for conventional boats will hinder the transition.”

To that end, ZF Marine last year announced that it was growing its presence in Louisiana by securing a new location for their Gulf of Mexico/Inland Waterway sales and service operations. Present in greater New Orleans since late 1996, the original office was the first satellite location outside of ZF’s North American marine headquarters, providing support for the commercial vessel industry in the Gulf of Mexico.

Twenty years later, the new location, located in Elmwood, LA, is almost triple the size of the current facility. It will also allow the firm to ramp up service to inland waterway customers.

Boasting support for repair and overhaul activities, the new office will provide localized spare parts as well as complete swing unit warehousing. The facility will also be able to support training activities for all of ZF Marine’s product families. The location is planned to open in the second quarter of 2017. But, says ZF’s Meissner, offices and equipment are only one part of the ZF story.

“Each project has a Project Manager that ‘quarterbacks’ the entire activity. In-house Naval Architects and Application Engineers work with the shipyard and the vessel owner to review and approve each application,” he said, adding enthusiastically, “Field Engineers and Technicians help coordinate and check the physical installation of the complete system, bringing the system online, and participate in both builder’s trials and customer acceptance trials. Once the vessel is in service we have a local support network that can meet the needs of our customers with time sensitive parts and service support wherever the vessel is.”

What happens next in terms of inland penetration for ZF will depend on a lot of things, none more important than demonstrating to a traditionally conservative market that future support will match and exceed early adopter successes. Firms like ACBL will accept nothing less, and for his part, Meissner, in a video interview with Maritime Reporter’s Greg Trauthwein in late 2016, said simply, “We’re doubling down on the inland waterways.” That kind of trust, matched by collaborative support, bodes well for the future of Z-Drives in brown water.

(As published in the July 2017 edition of Marine News)

Read Z-Drive Collaboration on the Inland Waterways Expands in Pdf, Flash or Html5 edition of July 2017 Marine News

Other stories from July 2017 issue

Content

- Op/Ed: The Real Story Behind the Attack on SMFF Regulations page: 20

- For Payroll Purposes, is Your Seaman Really a Seaman? page: 24

- The Evolving ATB Jones Act Business Model page: 28

- The Strong and Silent Type page: 34

- Sizing Up the Market, Scaling Solutions to Size page: 38

- Z-Drive Collaboration on the Inland Waterways Expands page: 44

- Grooving the Way: Back to the Future page: 47

- Tech File: NS Workboat page: 52