Gibbs & Cox: Historic Ship Designer Turns 90

Hindsight, they say is 20/20, and in this regard renowned design house Gibbs & Cox has nine decades in the rear view mirror on which to lean. We recently caught up with Chris Deegan, President and CEO of Gibbs & Cox, celebrating its 90th anniversary in 2019, to discuss the organization’s rich history and promising future.

When you took the top spot at Gibbs & Cox in 2016, what were your goals for the organization?

As a company that designs everything from yachts to work boats to destroyers, I wanted to reassert G&C as the global leader in the naval architecture and marine engineering industry. Our Board of Directors challenged us with growth in a flat market, and we have exceeded the target each year, needing new benchmarks along the way. Our success is honestly easy to understand: provide a superior product to our customers, and treat our people well. I want every person in the company to feel valued and recognized as an important contributor to our success. If we take care of the people, the people take care of the customer.

Please give a “By the Numbers” overview of Gibbs & Cox today.

This year we celebrate our 90th year of incorporation, and less than one tenth of one percent of companies reach 90! At 400 people and seven domestic locations, G&C today is the largest independent, privately held ship design firm in the world. Ships are all we do. Nearly 7,000 vessels have sailed to our designs, including 30 classes of combatants for 44 nations. In 2015 we acquired Donald L. Blount & Associates (DLBA) bringing us an innovation center in the commercial, workboat and recreational markets. Domestically, we augment government program office and engineering teams in the US Navy, Missile Defense Agency and USCG. Our role as a shipyard Design Agent spans many shipyards needing surge engineering and design services. Internationally, we support shipyards in Halifax and Vancouver; and in 2017 we opened our Canberra, Australia office to align us with the Australian naval expansion program. We remain aligned with customers via expertise in important and emerging markets such as polar ice breakers, autonomous surface programs, and regulatory changes in ballast water treatment and Tier 4 emissions.

As one of the few ISO 9000 certified naval architecture and marine engineering firms, we welcome annual site audits of our processes and consistently record excellent results. We have a robust quality assurance system unmatched in our sector of the industry, supported by a library of management and technical guidelines built from lessons learned of previous classes which we tailor to each project based on customer preference.

In the past three years we have recorded our highest Customer Sat-isfaction ratings, our highest quality recordings and the highest Employee Satisfaction scores in the 15 years of these surveys. In an extremely tight job market, our attrition rate remains well under 10% per year. New employees have referred to us as a “destination” employer…once again proving if you take care of the people, the people take care of the customer.  Image: The Arleigh Burke design has been the workhorse of the US Navy for over 20 years, and will be for another 40-50 years. Photo courtesy Gibbs & Cox/U.S. NavyThe manner in which ships are designed has evolved mightily since G&C opened its doors in 1929. When you look at the evolution of ship design, what do you count as the most influential/important technical advance?

Image: The Arleigh Burke design has been the workhorse of the US Navy for over 20 years, and will be for another 40-50 years. Photo courtesy Gibbs & Cox/U.S. NavyThe manner in which ships are designed has evolved mightily since G&C opened its doors in 1929. When you look at the evolution of ship design, what do you count as the most influential/important technical advance?

Computer Aided Design (CAD) continues to be the most influential and transformational technical advance in the field of naval architecture. We were an early adapter of CAD and helped advance its evolution since the late 1970’s. Since those early days we have seen various CAD programs mature, and the ability to model production information directly into plate cutters, pipe bending machines and other production tools has been the most influential technical advance in the industry. In looking to the future CAD firms are developing Augmented Reality applications, and within the next decade we can see data being accessed by Artificial Intelligence applications.

Gibbs & Cox has had a long-standing relationship with the U.S. Navy, a customer with high demands and expectations. What’s the secret for building and maintaining a strong relationship with this demanding customer?

I don’t see it as a secret, but a detailed understanding of the specification, past performance and expert knowledge goes a long way. The Navy has done an excellent job rebuilding its internal world class capability since its engineering workforce was gutted 25 years ago. NAVSEA is respected worldwide for its depth and breadth of talent, capabilities and facilities. Our niche with our Navy customer are peer-level discussions. Since we support the shipbuilding industry around the world, our detail design and production support capabilities offer a unique perspective to Navy programs and other government teams as well.

The U.S. Navy is unique in that it must project decades in advance its operational requirements, while maintaining a focus on today. What is the trick for a Gibbs & Cox to help design vessels that are – from cradle to grave – efficient and successful in their mission.

No tricks, it is always about customer alignment. Like any industry, listening to the customer is critical. For the Navy and future combatants, energy loads and how to most efficiently supply that energy to future weapon systems (lasers, directed energy and electronic attack systems) is influencing today’s concepts. Even for the Navy’s nascent surface ship autonomous missions, relating specifications our commercial and recreational markets provides fresh insights to warfighting specification tradeoffs. Naval architecture is very much an evolutionary business, and our breadth and depth offer a unique perspective for creative design and support alternatives. As such, we’ll have a number of 30+ year employees say “we did something like that in 1999, or for NOAA, Coast Guard, or for Taiwan or Australia.”

Please discuss your Navy business projections for the coming decade.

The near term is promising for the government-based ship design and marine engineering industry. I qualify with “government” because 90% of the Navy’s five-year SCN portfolio targets HII and General Dynamics, each possessing their own in house engineering and design workforces, with little room for third party design and engineering competition and innovation (e.g. submarines, big deck carriers, destroyers, amphibious ships, etc). We targeted FFGX and successfully staffed 2 of the 5 Concept Design teams, Lockheed Martin’s Freedom and Fincantieri FREMM-class variants (LM recently opted out of the Detail Design and Construction bidding). Beyond FFGX, the Navy’s FY 2020 President’s Budget includes more auxiliary ships and a growing autonomous ships portfolio. G&C is well positioned to support the Navy in many of these programs and particularly the autonomous market.

Ship design, particularly ship design for the U.S. Navy, requires continual investment. Please share with us how G&C is investing today.

Our recent growth has been organic, as such we find it necessary to have a robust dialogue with our customers to understand where they are headed to remain aligned. In the past five years, we have lead the industry in low cost 3D modelling supporting not only ships, but aviation assets and AEGIS Ashore as well. In 2017 we purchased our first 3D printer, and this fall we will be introducing Virtual and Augmented Reality at the International Workboat and Fort Lauderdale International Boat Shows. We’ve also invested in autonomous HM&E solutions, cyber security and top side integration capabilities. While Gibbs & Cox is best known recently for its military work, it has an ample and growing commercial design base, too. All photos: Gibbs & Cox

While Gibbs & Cox is best known recently for its military work, it has an ample and growing commercial design base, too. All photos: Gibbs & Cox

Given Gibbs & Cox’s history, the Navy focus is warranted. But let’s look outside the Navy for a moment. Can you give update and insight on your business today and prospects for everything that is not a grey hull?

Gibbs & Cox continues to expand outside of our naval market, following a decent amount of ship design opportunities in NOAA, MARAD, USCG, as well as those at the state and city level. This market is very competitive with no Jones Act protections, and there is an increasing dependence on parent designs, which are often sourced overseas. Outside of the government focus, our DLBA business has been a tremendous addition to the company. The production boat market has been an increasing amount of business for DLBA, as has the sportfish market with some outstanding builders in the Carolinas. Though the yacht design market has shifted to Europe in recent years, we are still pursuing interests here and abroad.

I know there are many, but if you were forced to select just one ship, one design, one project that you feel best defines G&C’s history, what would that be and why?

The Arleigh Burke design has been the workhorse of the US Navy for over 20 years, and will be for another 40-50 years. We were aligned with the Navy and industry from the onset in the mid-1980s to develop the most capable warship, introduced Computer Aided Design along the way, were teamed with the Navy and industry for each flight upgrade, and today actively support the PMS 400 program office on Flight III integration. Were there warts along the way? Absolutely! But that is how a 90-year-old company continues to excel, learning and adjusting, applying lessons learned to each subsequent vessel.

Every position has its challenges. What do you consider to be your greatest challenge in leading Gibbs & Cox, and how do you address this challenge?

I am truly excited about autonomous vessels and the growth in design opportunities around the globe. This adds incredible variety to our staff as they work on interesting projects throughout any given year. Contrary to market trends, we’ve done a great job finding the design and engineering talent to meet our demands. (Niche skills such as cyber remain difficult to fill). Though our attrition remains far below the industry, we are a people business and retaining staff is my biggest concern. Ship design is heavy on maintaining quality and deadline driven projects. It is demanding field, and the number one reason people leave us is to leave the maritime industry. To address this, G&C is improving our initial interviewing filters. Once on board, we perform annual skills surveys of our staff to measure the talent we have onboard, and includes a personal skills assessment of nearly 400 categories. With this, we tailor each employee’s aspirations to our projects, and in turn we see what skills we need to acquire corporately. We also have developed 19 career management guidelines to aide an employee’s self-development.

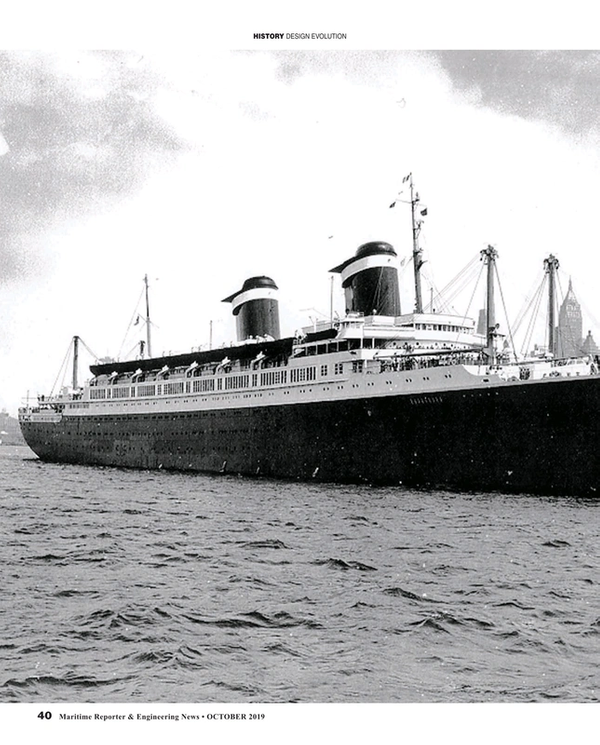

The SS United States. Photo: Gibbs & Cox

The SS United States. Photo: Gibbs & Cox

Read Gibbs & Cox: Historic Ship Designer Turns 90 in Pdf, Flash or Html5 edition of October 2019 Maritime Reporter

Other stories from October 2019 issue

Content

- Containership Fires page: 16

- Interview: Nigel Shewring R&D Director, Hempel page: 24

- Maritime History & the Panama Canal page: 26

- C-Job CEO Basjan Faber was Born to Design page: 34

- Gibbs & Cox: Historic Ship Designer Turns 90 page: 40

- Ship Design & The Inevitability of Change page: 46

- Ship Design: Evolving for Efficiency, Compliance page: 50

- Robert Allan Ltd.: The Evolution of Marine Design page: 52

- Interview: Cory Wood, VP, Bristol Harbor Group page: 54

- Maritime 2050: Facing the Decarbonization Challenge page: 58

- ABS & the Future of Classification page: 60