Dry Dock

-

- Heger Dry Dock Gets to Work on AFDM for U.S. Navy Maritime Reporter, Jan 2023 #32

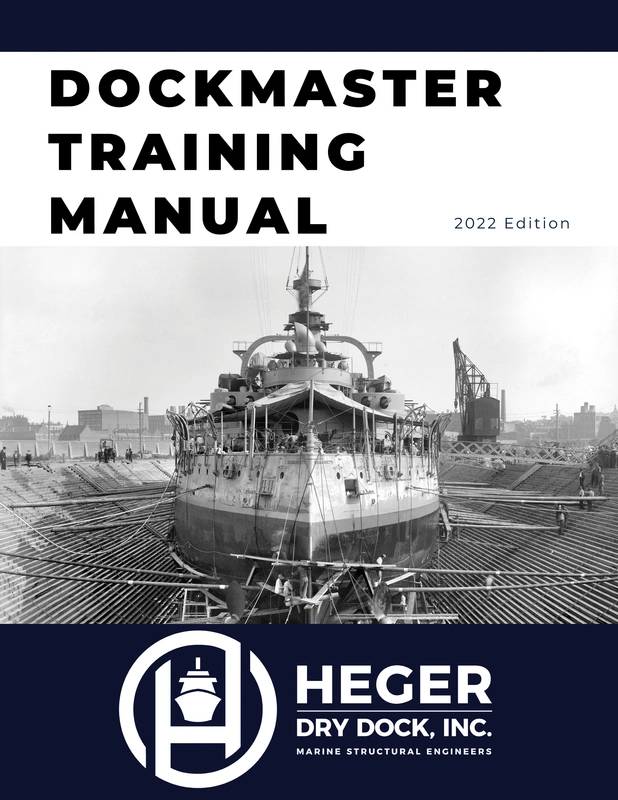

Born in 1998 and celebrating its 25th anniversary in 2023, Heger Dry Dock holds a unique position as one of the few engineering firms in the world dedicated to the design and lifecycle engineering of drydocks, primarily floating dry docks. Premal Shah, P.E., President and Principal Engineer, discussed some of the company’s recent contract wins with Maritime Reporter & Engineering News.

Specializing in the design and lifecycle maintenance of floating dry docks, Heger Dry Docks was founded 25 years ago, and still run today by one of its co-founders, Bob Heger. “We are experts in floating dry dock designs,” said Shah. “We're a design and engineering company and we deal with dry docks; about 90% of our work deals with floating dry docks.”

While all of its business is in the U.S., it has experience internationally, designing drydocks for customer that have had them built outside the country. “There is simply not enough capacity in the U.S. shipyards to build something large [like a drydock],” said Shah. “Most of the larger shipyards in the U.S. are busy building Navy ships, so they don't want to take time away from their workforce to build a one-off dry dock. So most of our large designs get built elsewhere outside of the U.S.”

While the capability to build the drydocks lies mostly outside of the U.S., Shah estimates there is a high demand for the units in the U.S., a “shortage of dry docks.” A strong driver recently has been the U.S. Navy and its shipyard infrastructure optimization program (SIOP), which is working to identify – and help alleviate – bottlenecks that it sees in the coming 20 to 30 years, particularly as it embarks on a substantial shipbuilding program through 2035.

“They've essentially started these massive programs, billions of dollars of funding allocated to the four main shipyards: Portsmouth Naval, Norfolk Naval, Puget Sound, and Pearl Harbor: and they're initiating all these efforts to build new dry docks,” said Shah.

While graving drydocks have a much longer life span, with units built in the 1920s and after still active, they represent mammoth civil engineering projects with similarly sized mammoth budgets in dollars and manpower. A floating drydock has a much more modest life-span – 50 years or more if properly maintain, but a similarly sized floating unit is much cheaper.

Photo courtesy Heger Drydock

Photo courtesy Heger Drydock“The main driver is the cost. Let's say you're setting up a shipyard from ground zero and you want to invest in a dry dock that can lift a substantial capacity vessel,” said Shah. “A graving dry dock is 10 to 15 times more expensive than a floating dry dock. From a capital investment perspective, it makes more sense to have a floating dry dock.”

“I can't remember the last time anybody designed or built a graving dry dock for a commercial yard,” said Shah. “But the Navy, of course, can afford them, and they're looking for longevity.” He notes that most of the Navy yards do not operate a floating dry dock.

Depending on vessel size, there are other options to dry dock a vessel, with travel lifts, ship lifts and marine railways offering solutions. But if you are targeting vessels in your business model that are over 10,000 tons, “your only options are a floating dry dock or a graving dry dock,” said Shah.

Heger Dry Dock has a long list of projects and clients over the past 25 years, but a more recent contract to build a U.S. Navy asset, an Auxiliary Floating Dry Dock Medium (AFDM), is keeping the company busy. Measuring 700 x 160 ft. with a lifting capacity of 18,000 long tons, the AFDM will be designed to accommodate destroyers, cruisers, the new LCS type vessels which are homeported in and around San Diego.

“There were a bunch of them [drydocks] built in the 1930s and 1940s, and there were some other smaller dry docks built in the 1960s,” said Shah. “But nobody has designed or built an AFDM or any kind of floating dry dock for the Navy in the past 40-plus years.”

Heger Dry Dock were recently awarded a new AFDM design project along with its design-build partner in Mobile Alabama, Austal USA. “So we're designing this AFDM, which is a significant project for us because nobody has done this in a few decades,” said Shah.

When built at Austal in Mobile, the AFDM will be located at the naval base in San Diego.

“Once it's all done, it will be a huge feather in our cap, because a privately held company has not designed a floating dock for the Navy in many decades,” said Shah.

-

- Inland Drydocks: Location, Location, Location Marine News, May 2018 #54

A recent dry dock rehab project in Chicago provides new options and money saving opportunities for inland and Great Lakes stakeholders alike.From software to steel plating, Indiana-based TPG Marine Enterprises provides a range of services in the Great Lakes and inland waterways markets. River based tug and

-

- Dry Dock Conference 2014 Maritime Reporter, Aug 2014 #52

Scheduled for December 1-2, 2014 in New Orleans Dry Dock Conference 2014 is the eighth in a series of international Conferences held every two to three years. This year’s conference will be held December 1-2, 2014 in New Orleans. Among the highlights of the upcoming New Orleans’ conference will be a

-

- Grand Bahama Shipyard: Investing in the Future Maritime Reporter, Sep 2016 #18

customer demand by upgrading workshops, purchasing new machinery and tooling, as well as expanding its wet berth capabilities to relieve pressure off dry dock utilization and move vessels out of dry dock and into service faster. In all, GBSL invested in three key pieces of equipment in January of 2016.

-

- International Appeal With Local Customer Service Feel Maritime Reporter, Jan 2001 #33

A tlantic Marine Inc and Atlantic / 1 Dry Dock Corp have forged an enviable reputation around the JL JLglobe in all aspects of vessel construction, conversion and repair. The yards offer ship owners modern physical facilities, technical capabilities and organizational experience, and are conveniently

-

- Pictou Industries Completes Third Enlargement Of Crandall R a i l w a y Drydock Maritime Reporter, Jan 1989 #46

currently under the management of Canadian Shipbuilding and Engineering Limited, who also manage facilities at Thunder Bay and Port Weller Dry Dock on the Great Lakes. According to Crandall Dry Dock Engineers, if a railway drydock is initially well designed it not only allows security and

-

- Senesco Marine Christens New Drydock Maritime Reporter, Nov 2003 #29

Senesco Marine last month christened its new dry dock and celebrated the dry dock's receipt of a key certification that has already significantly increased the company's repair business. The certification bestowed upon the Leslie G by Heger Dry Dock, Inc, of Holliston, Mass., now allows the shipyard t

-

- Signal International Maritime Reporter, Aug 2013 #50

offers new construction, rig and ship repair, offshore and technical services. Marine construction and repair needs are complimented by three dry docks; a 30,000-ton lift rig dock, a 22,000-ton Panamax dry dock and a 4,500-ton lift dry dock. In Mobile, Ala., Signal Ship Repair (SSR) offers 4

-

- Port Of Portland's Drydock —Largest On West Coast— Arrives At Swan Island Yard Maritime Reporter, Nov 1978 #6

million authorized. The effect may be that the project could come off the tax rolls in two years, instead of the three to five predicted. In the new Dry Dock 4, the Port of Portland will have the largest floating drydock on the U.S. West Coast, and the third largest in the world. The new dock will

-

- Dry Dock Association Elects Massa President Maritime Reporter, Jun 15, 1977 #50

Alfred C. Bruggemann, outgoing president of the New York and New Jersey Dry Dock Association, has announced the election of Robert L. Massa as president for the new term. Mr. Massa was born and educated on Staten Island, N.Y., and attended Wagner College and Rutgers University. After serving his

-

- Rules For Floating Dry Dock Construction Published By ABS Maritime Reporter, Jul 1977 #4

A new Rule book, "Rules for Building and Classing Steel Floating Dry Docks," has been published by the American Bureau of Shipping (ABS). The Rules apply to floating dry docks over 61 meters (200 feet) in length, but can be applied, subject to special considerations, to smaller structures. The

-

- Streamlined Service for the Offshore Sector Marine News, May 2014 #53

to an equally vibrant offshore oil and gas industry and its support sector. The ABC’s of High Blocking Signal Ship Repair (SSR) has the ability to dry dock up to 600 foot vessels draughting over 24 feet of water on 12 foot blocks. While the standard blocking is six feet, the high blocking scenario gives

-

)

April 2025 - Maritime Reporter and Engineering News page: 27

)

April 2025 - Maritime Reporter and Engineering News page: 27carriers. “FPSOs take a lot of steel; they’re big; they take up a ton of space. I can probably build three, maybe four gas carriers per square meter of dry dock space versus one FPSO; so I’m making more money building gas carriers than I am building FPSOs,” observed Tremblay. FPSO MAINTENANCE & THE DIGITAL

-

)

February 2025 - Maritime Reporter and Engineering News page: 22

)

February 2025 - Maritime Reporter and Engineering News page: 22of electrostatic Ariana Psomas, Global Segment Di- traditional antifouling coatings. “An application of marine fouling coatings, rector New Build & Dry Dock, PPG. exciting addition to sustainability is a process that in practical application SIGMAGLIDE, is a fouling release that both SIGMAGLIDE and

-

)

February 2025 - Maritime Reporter and Engineering News page: 21

)

February 2025 - Maritime Reporter and Engineering News page: 21for fouling control available on the market from the main coating’s suppliers, all making per- formance claims. “Sa? nah attends around 200 – 250 dry docks per year on be- half of the owner as project managers, and therefore we have an in-depth reference point of fouling coating performance. A particular

-

)

November 2024 - Marine News page: 33

)

November 2024 - Marine News page: 33reliable lift fan system, as well as an activated damper system. We can now replace the skirts with the boat in the water. We don’t need to go into a dry dock to do this type of work.” There is a high degree of automation. “These vessels are more or less like ? y by wire on water,” he said. “I say that

-

)

October 2024 - Marine News page: 34

)

October 2024 - Marine News page: 34, in Mobile, is a full- service ship repair facility serving both commercial and government customers. The yard features a 787- by 164-foot ? oating dry-dock, DD Alabama— one of the largest in the U.S.—and ? ve pier locations to accommodate vessels up to 1,000 feet in length. All photos courtesy

-

)

October 2024 - Marine News page: 11

)

October 2024 - Marine News page: 11its operations since opening in 2019? Will you please give an overview of its current facilities, equipment and capabilities? ESR started out with a dry dock, its dockmaster and a handful of folks and borrowed equipment from sister company, Nichols Brothers. As we close in on ? ve years of operations

-

)

September 2024 - Marine Technology Reporter page: 22

)

September 2024 - Marine Technology Reporter page: 22of repairing ships and boats of nearly every shape and and underwater hull. The Pisces had a 100% blast on the size. The shipyard is massive, with three dry docks and one freeboard and spot on the underwater hull,” said Braddock. ? oating dock to handle a volume of work. The shipyard also The Pisces was

-

)

August 2024 - Marine News page: 20

)

August 2024 - Marine News page: 20with Tier 1 yards for rapid repairs and builds. We have put global in? uence, the United States must project strength forward a grant application for a dry dock that would cre- and security in the maritime domain,” said Senator Rubio. ate enormous economic growth for our area and relieve a “Congress must

-

)

August 2024 - Marine News page: 8

)

August 2024 - Marine News page: 8By the Numbers 2024 MARAD Small Shipyard Grants The U.S. Department of Transportation’s Maritime Admin- Florida region. It will receive $997,678 for its Dry-Dock istration (MARAD) announced $8.75 million in grant awards Strengthening Project of the A.W. HENDRY drydock to to 15 small shipyards in 12 states

-

)

February 2024 - Maritime Reporter and Engineering News page: 31

)

February 2024 - Maritime Reporter and Engineering News page: 31it was the overriding bearing material migrating through the lubrication system. theme at Sea Asia.” Rudder, propeller and shaft needed to be removed in dry dock However, insurer Gard remains concerned about EAL fail- before the required repairs could be completed. ure, and company analysts voiced them in

-

)

November 2023 - Maritime Reporter and Engineering News page: 80

)

November 2023 - Maritime Reporter and Engineering News page: 80. . . . . . . . . . . . . . . . . .www.clickbond.com/MR19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(775) 885-8000 41 . . . . .Crandall Dry Dock Engineers, Inc. . . . . . . . . . . . . . . . . . . . . . . .www.crandalldrydock.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-

)

November 2023 - Maritime Reporter and Engineering News page: 41

)

November 2023 - Maritime Reporter and Engineering News page: 41Crandall Dry Dock Engineers, Inc. CRANDALL is happy to announce it is back in DRY DOCK ENGINEERS, INC. business and ready to serve you again! Established 1854 Crandall had been on hiatus since 2021, due to the illness and loss of former owner, P. Brian Dui y. Now under the leadership of Brian’s daughter

-

)

June 2023 - Marine News page: 28

)

June 2023 - Marine News page: 28conception of the Swift Ships LCU 1700 Swift Ships known as LAW, and are in the process of ? nal require- contract for a news auxiliary ? oating dry dock medium ments approval of the Capabilities Development Docu- (AFDM) for the Navy. To replace the Navy’s oceangoing ment (CDD). The Concept Studies

-

)

August 2023 - Maritime Reporter and Engineering News page: 48

)

August 2023 - Maritime Reporter and Engineering News page: 48will be located at Khalifa Port and encompass a 45,000 sq. m. shipyard and repair facility, 350m quay wall for vessel a? oat repair, and a ? oating dry dock for vessel maintenance and refurbishment. The ? oating dry dock is expected to commence op- erations in July of 2023, while the shipyard has already

-

)

August 2023 - Marine News page: 30

)

August 2023 - Marine News page: 30industry can now be serviced right here in the Port of New (MMSC) and Constellation Class Frigates can be out? tted York & New Jersey at Bayonne Dry Dock,” Rooney said. to near completion and tested inside climate-controlled fa- “Everything from emergency support and law enforce- cilities before being

-

)

August 2023 - Marine News page: 29

)

August 2023 - Marine News page: 29more projects and improved ef? ciency. the demands of vessel schedules. We hope to shorten the Southern California-based Marine Group Boat Works, dry dock time frame for them.” which performs a mix of yacht, commercial and govern- In addition, the Stevens Towing Shipyard facility will ment vessel repair

-

)

April 2023 - Marine News page: 14

)

April 2023 - Marine News page: 14should happen now. merce. They got it done. We’re not done with Subchapter M. There are going to Do you think it’s even possible for the industry be dry dock and internal structural exams, COI renewals to comply given the supply chain challenges, every

-

)

February 2023 - Marine News page: 34

)

February 2023 - Marine News page: 34gines replaced with Tier 3 compliant power from EMD, in Crowther catamaran design, for Patriot Offshore Maritime 2020, with work performed at Caddell Dry Dock in Stat- Services LLC – a new entrant to the wind sector. Vine- en Island, N.Y. Ultimately, the three-vessel ? eet will need yard Wind, which the

-

)

January 2023 - Maritime Reporter and Engineering News page: 33

)

January 2023 - Maritime Reporter and Engineering News page: 33Naval, Norfolk Naval, Puget Sound, and com/wp-content/ Pearl Harbor: and they’re initiating all these efforts to build uploads/2022/06/2018- new dry docks,” said Shah. DOCKMASTER- While graving drydocks have a much longer life span, with MANUAL-NEW- units built in the 1920s and after still active,

-

)

January 2023 - Maritime Reporter and Engineering News page: 32

)

January 2023 - Maritime Reporter and Engineering News page: 32SHIP REPAIR HEGER DRY DOCK GETS TO WORK ON AFDM FOR U.S. NAVY Born in 1998 and celebrating its 25th anniversary in 2023, Heger Dry Dock holds a unique position as one of the few engineering ? rms in the world dedicated to the design and lifecycle engineering of drydocks, primarily ? oating dry docks.

-

)

January 2023 - Maritime Reporter and Engineering News page: 31

)

January 2023 - Maritime Reporter and Engineering News page: 31Assemblyman William B. Sampson IV (NJ District 31); Kevin O’Toole, Chairman, Port Authority NY/NY; Msgr. David Cassato; Mike Cranston, President Bayonne Dry Dock & Repair; Clare Cranston, widow of Detective Christopher Cranston; Bethann Rooney, Director, Port Authority NY/NJ, Msgr. Jamie Gigantiello, FDNY

-

)

January 2023 - Maritime Reporter and Engineering News page: 30

)

January 2023 - Maritime Reporter and Engineering News page: 30in the All images courtesy Eric Haun U.S. Northeast, opening up a new stream of sales for the Bayonne, N.J. re? t and repair yard. BAYONNE DRY DOCK CHRISTENS NEW MOBILE BOAT HOIST New boat lift adds capacity and honors a fallen hero By Eric Haun ayonne Dry Dock & Repair Corp held a chris- someone

-

)

January 2023 - Maritime Reporter and Engineering News page: 29

)

January 2023 - Maritime Reporter and Engineering News page: 29facilities around the Gulf coast and notably the UAE, there are two other large facilities of note. Re- cent expansion at the recently rebranded Asyad Dry Dock in Duqm, Oman, has pitched the yard high on the region’s list of key players. Previously Oman Dry- dock Company, the shiprepairer’s new name

-

)

January 2023 - Maritime Reporter and Engineering News page: 25

)

January 2023 - Maritime Reporter and Engineering News page: 25SHIP REPAIR MIDDLE EAST Asyad Dry Dock in Duqm, Oman, was previously Oman Drydock Company. Its new name re? ects its ownership by Oman shipping and logistics group, Asyad. Image courtesy ASRY n the 45 years since the Arab Shipbuilding & Repair Willem Moelker is Sales & Marketing Director at Sharjah- Yard