Demanding Times for DSC Dredge

By Joseph Keefe

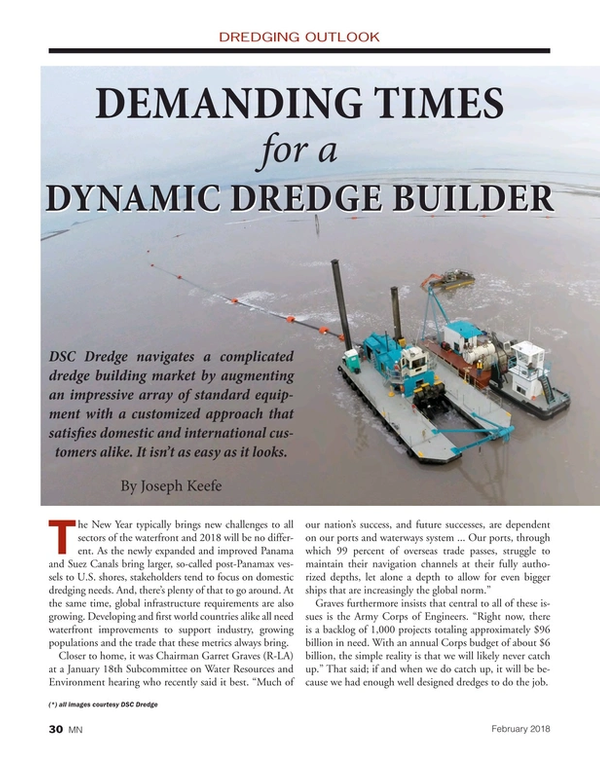

The dynamic dredge builder navigates a complicated dredge building market by augmenting an impressive array of standard equipment with a customized approach that satisfies domestic and international customers alike. It isn’t as easy as it looks.

The New Year typically brings new challenges to all sectors of the waterfront and 2018 will be no different. As the newly expanded and improved Panama and Suez Canals bring larger, so-called post-Panamax vessels to U.S. shores, stakeholders tend to focus on domestic dredging needs. And, there’s plenty of that to go around. At the same time, global infrastructure requirements are also growing. Developing and first world countries alike all need waterfront improvements to support industry, growing populations and the trade that these metrics always bring.

Closer to home, it was Chairman Garret Graves (R-La.) at a January 18 Subcommittee on Water Resources and Environment hearing who recently said it best. “Much of our nation’s success, and future successes, are dependent on our ports and waterways system ... Our ports, through which 99 percent of overseas trade passes, struggle to maintain their navigation channels at their fully authorized depths, let alone a depth to allow for even bigger ships that are increasingly the global norm.”

Graves furthermore insists that central to all of these issues is the Army Corps of Engineers. “Right now, there is a backlog of 1,000 projects totaling approximately $96 billion in need. With an annual Corps budget of about $6 billion, the simple reality is that we will likely never catch up.” That said, if and when we do catch up, it will be because we had enough well designed dredges to do the job.

Underpinning current events is the fundamental truth that the need for dredging will never go away, and the recapitalization of existing equipment in this demanding trade – here and across the big pond – is always an ongoing process. What’s unusual about that reality is that a U.S.-based builder can compete, and compete well on the international side of the equation. Bob Wetta, President and CEO of DSC Dredge, says that the key to that success is to keep his firm at the forefront of current events, as well as the latest dredging and engineering trends for the business. That’s easier said than done.

DSC Dredge: By the Numbers

With deep roots stretching all the way back to the 1950s, DSC Dredge is at its heart, a family business that has evolved over time into one the nation’s premier builders of dredging equipment. Over time, the firm’s success – built by a laser focus on customization and quality – led to growth. In 2010 the corporation consolidated its subsidiaries, and DSC Dredge, LLC (DSC), was born. The reorganization brought together Dredging Supply Company and dredge manufacturers W&S and Best Equipment to gain maximum efficiencies in the day-to-day operations and administration of all of the facilities.

DSC has three manufacturing operations in the U.S., and engineers customized dredging solutions to meet specific application needs. More importantly, the firm is active in both international and domestic markets. Bob Wetta explains the formula, saying, “The split over the past 5+ years has been approximately 50/50. The only time we saw a little downward slope in the international market was when oil prices started dropping in 2014. It started equalizing in 2016.”

Today, DSC has equipment deployed to as many as 40 countries. Where U.S. boatbuilders are often considered to be too expensive for foreign buyers, roughly half of the DSC output is still exported. “I believe reputation has played a big part in our international efforts. DSC stands behind our products,” says Wetta, adding, “We commission the equipment, train the end users and make return visits to make sure the equipment is functioning properly. Another thing DSC promotes that many other dredge manufactures do not is that we don’t privatize the maintenance parts on our equipment. We install other OEM equipment with their original tags so our clients have the opportunity to source components in their local markets.”

In a given year, DSC averages between 130-150 employees. From 2010 through 2017, its average output was 20 major equipment projects annually, with actual output dictated by the size of the projects and man-hours required. Wetta explains, “Year to year, it can look a little different. For example, if we had two large custom dredges (say 24” dredges), then the output might only be 10 dredges that year. Conversely, if all of the dredges we smaller to mid-size we might deliver as many as 30.”

Today’s Dredge Markets

One might think that with all the focus on infrastructure here and the deepening operations underway to meet the post-Panamax tonnage, that the dredge market would be hot. According to DSC Dredge, it remains a mixed bag as we head into 2018. “From our manufacturing prospective, I would say the domestic market is picking up on the aggregate side of the market. Sand and gravel producers are investing in new operations and new equipment. I think the aggregate industry is showing confidence based on the current U.S.A. administration and their commitment to our infrastructure,” said Wetta. Offshore, he adds, the foreign market still has certain geographical regions that are strong while others are very soft. The soft markets are typically countries that depend on oil for the primary economy. That said, Wetta remains optimistic for the near term. “I do believe the demand is there for DSC to continue a 50/50 split for domestic to international sales ratio.”

Past success is no guarantee of future performance and that means that all stakeholders in this sector need to have a well planned and executed business plan. DSC, for example, has sales representation in several countries overseas. Focusing on the active markets while trying to establish formal and exclusive representation is how DSC stays ahead of the market. Wetta told Marine News in January, “We need a partner in for the long haul and one that is committed to DSC. In other areas, we may have project specific representatives that help through some of the barriers faced with exporting. DSC’s international sales office is based out of Baltimore. BWI offers good flight options for our Director of International Sales (Charles Sinunu) to make international trips as needed.”

Another part of the DSC philosophy involves the production of both standard dredge designs, as well as custom projects. “Our niche market is definitely custom designed dredges. DSC averages about three to four custom design projects a year and the balance is made up of standard designed equipment. But the revenue split on these is fairly equal,” said Wetta. In practice, the Greenbush, Mich. facility focuses on standard design dredges – the Badger and Wolverine Class dredges. The firm’s Poplarville, Miss. and Reserve, La. facilities both aim to have standard dredges in stock or at least at some point in the production queue. These southern DSC facilities focus on 8” through 18” dredges for speculative sale and include the well-known DSC Moray, Shark and Barracuda Class dredges.

Big Challenges, Innovative Solutions

It is one thing to talk about selling here and abroad, and quite another to execute the plan in practice. That’s because while foreign buyers are still using EPA Tier 3 engines, the U.S. markets now demand Tier 4 to meet regulations. As manufacturers gear up for production, the difference impacts both costs and logistics. For example, where a yard or builder might want to stock several units so as to be able to quickly respond to demand, that’s not always possible or practical when different markets demand different equipment.

Wetta acknowledges the issue, while laying out the DSC way of doing things. “This definitely does present some challenges but we have defined several products that have been repetitively sold in our export markets. I envision a mix on certain model dredges where we will stock both Tier 3 and tier 4 versions. Another thought is to have both engines sitting on our shop floor waiting for the buyer and have the ability to do a quick turnaround no matter where the final destination for the dredge will be. There is an added cost for the Tier 4 engines and that can vary from 130 percent to nearly 200 percent of the same engine in a Tier 3 configuration.”

Because today’s engines – at least on the domestic side – now need more after-treatment, dredge builders such as DSC have to redesign certain aspects of those hulls. “Obviously,” says Wetta, “this cost needs to be passed on. The cost to redesign a standard product is generally absorbed by DSC because the plan is to sell the standard design many times – let’s say we absorb the design cost by amortizing it over many units. Engineering and automation designs are generally factored into custom dredge designs so I don’t see a substantial change for our pricing metrics besides passing along the added material costs for the Tier 4 engines.”

In the end, however, ‘Tier’ configuration is not really a deciding factor for the dredge, but Tier 4 dredges may not be very useful in parts of the world that do not have clean, low sulphur fuel. Moreover, says Wetta, dredge requirements include differences such as dredging depth capability, production rate, pumping distance and the type of material to be dredged. “These differences are what allows DSC to offer custom designs to offer the most efficient dredge for the projects. The problem is typically the time it takes to design/build a custom dredge versus the client’s needs to have something immediately. Unfortunately, some companies can’t wait for a custom dredge to be built and they end up getting something that is over or under the requirements; in either case the wrong dredge and an inefficient option.”

Digging deeper into the Tier 4 quandary, dredges today are using SCR to achieve tier 4 compliance with aftermarket cooling. The Selective Catalytic Reduction system used to achieve Tier IV places a heavier cooling load on both the jacket water and after-cooler sections of the engine radiator. The jacket water heat rejection in these engines increased significantly, which dictated a larger radiator core and different fan selection. DSC, for example, had to shift from a stacked radiator core (auxiliary cooling cores on top of jacket water and after-cooler cores) to separate units in different locations. The end result actually allowed for better air flow though the dredge engine room, less radiator fan noise, and less pre-heat demand on the engine cooler.

Industry Firsts: Tier 4 Arrives

The U.S. Environmental Protection Agency (EPA) Tier 4 Final emissions standards went into effect for dredges last year. Engines ranging from 2,682 to 4,962 hp (2,000-3,700 kW) were first affected by the standards. But by October 2017, all new engines with a maximum power of 804 hp (600 kW) and greater must meet U.S. EPA Tier 4 Final emission standards. As all of that was happening, DSC and Caterpillar/Michigan CAT collaborated to install the first Tier 4 Final engine in a DSC Shark dredge – the C32 Tier 4 Final 1,125 hp.

This project was put together for a mineral producer working in the Great Salt Lake. The engine was installed in a custom 18” DSC Shark Class dredge. Wetta told Marine News, “While the Tier 4 requirement was not in effect at the time we manufactured the dredge, the client opted for this option. We have dredges with Tier 4 engines in production but they are for speculative sale. We do have several quoted at this time, as well.”

In this case, the C32 Tier 4 Final engine is a 32-liter 12-cylinder V-engine with horsepower ranges from 1,000 hp to 1,125 hp. The C32 has industry-leading torque of 4,056 foot-pounds at 1,200 rpm. Caterpillar was able to achieve the Tier 4 Final regulations in the C32 with the use of the Caterpillar NOx Reduction System and dual maintenance-free diesel oxidation catalysts (DOC).

More than Manufacturing: Outreach

Bob Wetta knows that running a good business probably isn’t enough in today’s rapidly changing waterfront. Beyond the day-to-day grind of delivering quality at home and overseas, outreach is also very much on his mind. As a past Board Member and past President/Board Chairman of the Western Dredging Association (WEDA), a non-profit technical professional organization devoted to the exchange of knowledge in fields related to dredging, navigation, marine engineering and construction, Wetta keeps DSC abreast of industry trends, politics and technology.

Along the way, he and DSC have done a lot of good. As the 2014 recipient of the WEDA’s ‘Dredger of the Year’ award, Wetta was recognized as the individual who provided outstanding benefit to the WEDA organization and to the dredging industry. Indeed, one of WEDA’s objectives is to recognize individuals and organizations for outstanding engineering and operational achievement. At the same time, Wetta remains dedicated to WEDA’s core goal of facilitating “the exchange of knowledge” between all stakeholders, as well as ensuring that the talent to get the job done remains on the dredging side of the equation.

“I believe one of the biggest challenges is educating our industry,” he explained, adding quickly, “I see too many companies purchasing equipment based on availability versus the best suited and efficient option. Another challenge is the competition in the skilled labor workforce. Our dredge builders (welders, fitters, hydraulic/mechanic technicians, electrical technicians, field service technicians) have the same crafts used by many other industries and we are all competing for the same resources.”

More than 500 dredges after DSC’s inception, the firm continues to balance a standard and proven array of dredges with the flexibility of custom design, when required. It’s a formula that allows Wetta to successfully market his products to more than 40 countries. And, while the business climate may change from year to year, that’s a business philosophy Bob Wetta is unlikely stray very far from. Hence, the next time you pass safely over shallow and restricted waters in North America and beyond, there’s a good chance that DSC Dredge had a hand in making that possible. That’s not likely to change, either.

(As published in the February 2018 edition of Marine News)

Read Demanding Times for DSC Dredge in Pdf, Flash or Html5 edition of February 2018 Marine News

Other stories from February 2018 issue

Content

- Interview: William P. Doyle - CEO, Dredging Contractors of America page: 14

- Op/Ed: AIWA - A National Asset Worth Funding page: 18

- What Does the Jones Act Mean for Offshore Wind? page: 20

- Managing the Big Risks of Marine Construction page: 22

- All Operators Should Follow These Lubrication Steps page: 25

- Op/Ed: Safeguarding Our Marine Transportation System page: 28

- Demanding Times for DSC Dredge page: 30

- Enhancing Historic Lake Michigan Docking Facilities page: 41

- Virtual Aid to Navigation: Here Now, Here to Stay page: 45

- Marine News Boat of the Month: February 2018 page: 48

- Ports of Indiana: Building on Success page: 236