UPC Foam Filled Fenders: The Ultimate Protector

Special Advertising Section Just as today's maritime industry is currently experiencing technological advances, the equipment that will be used to produce and adhere to these changes must follow the same beat — specifically in the arena of fendering systems. Bellflower, Calif.-based Urethane Products Corp. (UPC) has developed a proven system for today's stringent and demanding marine environments.

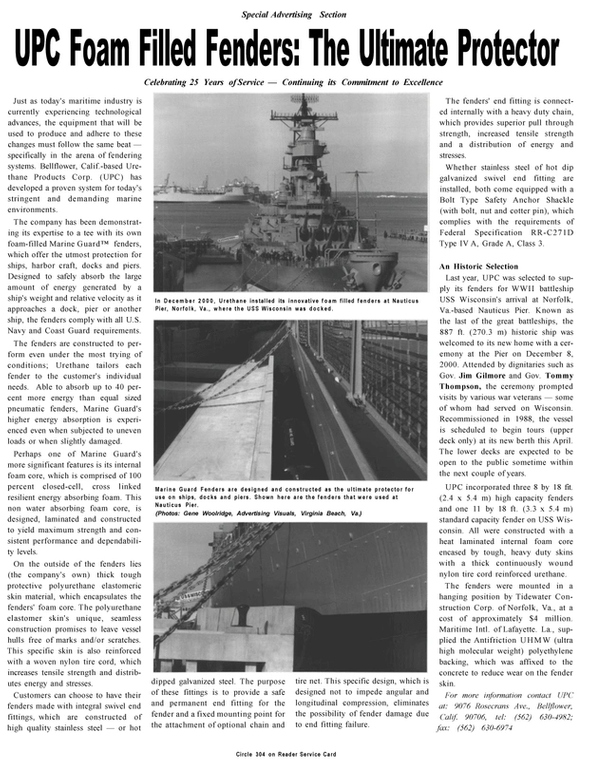

The company has been demonstrating its expertise to a tee with its own foam-filled Marine Guard™ fenders, which offer the utmost protection for ships, harbor craft, docks and piers.

Designed to safely absorb the large amount of energy generated by a ship's weight and relative velocity as it approaches a dock, pier or another ship, the fenders comply with all U.S.

Navy and Coast Guard requirements.

The fenders are constructed to perform even under the most trying of conditions; Urethane tailors each fender to the customer's individual needs. Able to absorb up to 40 percent more energy than equal sized pneumatic fenders, Marine Guard's higher energy absorption is experienced even when subjected to uneven loads or when slightly damaged.

Perhaps one of Marine Guard's more significant features is its internal foam core, which is comprised of 100 percent closed-cell, cross linked resilient energy absorbing foam. This non water absorbing foam core, is designed, laminated and constructed to yield maximum strength and consistent performance and dependability levels.

On the outside of the fenders lies (the company's own) thick tough protective polyurethane elastomeric skin material, which encapsulates the fenders' foam core. The polyurethane elastomer skin's unique, seamless construction promises to leave vessel hulls free of marks and/or scratches.

This specific skin is also reinforced with a woven nylon tire cord, which increases tensile strength and distributes energy and stresses.

Customers can choose to have their fenders made with integral swivel end fittings, which are constructed of high quality stainless steel — or hot dipped galvanized steel. The purpose of these fittings is to provide a safe and permanent end fitting for the fender and a fixed mounting point for the attachment of optional chain and tire net. This specific design, which is designed not to impede angular and longitudinal compression, eliminates the possibility of fender damage due to end fitting failure.

The fenders' end fitting is connected internally with a heavy duty chain, which provides superior pull through strength, increased tensile strength and a distribution of energy and stresses.

Whether stainless steel of hot dip galvanized swivel end fitting are installed, both come equipped with a Bolt Type Safety Anchor Shackle (with bolt, nut and cotter pin), which complies with the requirements of Federal Specification RR-C271D Type IV A, Grade A, Class 3.

An Historic Selection Last year, UPC was selected to supply its fenders for WWII battleship USS Wisconsin's arrival at Norfolk, Va.-based Nauticus Pier. Known as the last of the great battleships, the 887 ft. (270.3 m) historic ship was welcomed to its new home with a ceremony at the Pier on December 8, 2000. Attended by dignitaries such as Gov. Jim Gilmore and Gov. Tommy Thompson, the ceremony prompted visits by various war veterans — some of whom had served on Wisconsin.

Recommissioned in 1988, the vessel is scheduled to begin tours (upper deck only) at its new berth this April.

The lower decks are expected to be open to the public sometime within the next couple of years.

UPC incorporated three 8 by 18 fit.

(2.4 x 5.4 m) high capacity fenders and one 11 by 18 ft. (3.3 x 5.4 m) standard capacity fender on USS Wisconsin.

All were constructed with a heat laminated internal foam core encased by tough, heavy duty skins with a thick continuously wound nylon tire cord reinforced urethane.

The fenders were mounted in a hanging position by Tidewater Construction Corp. of Norfolk, Va., at a cost of approximately $4 million.

Maritime Intl. of Lafayette. La., supplied the Antifriction UHMW (ultra high molecular weight) polyethylene backing, which was affixed to the concrete to reduce wear on the fender skin.

For more information contact UPC at: 9076 Rosecrans Ave., Bellflower, Calif. 90706, tel: (562) 630-4982; fax: (562) 630-6974

Read UPC Foam Filled Fenders: The Ultimate Protector in Pdf, Flash or Html5 edition of March 2001 Maritime Reporter

Other stories from March 2001 issue

Content

- Diesel renaissance in Italy page: 8

- Dolphin Finds A Home page: 9

- (Fuel) Cells of Endeavor page: 10

- Maritime Transportation Is On Senate Subcommittee Agenda page: 11

- Aluminum Crewboat Built by Dubai Drydocks page: 12

- H o r i z o n Delivers Z - D r i v e Tug page: 14

- High Speed Ferry Set For Block Island page: 15

- Abu Dhabi Granted $ 5 0 M Naval Contract page: 15

- B2B for International Trade and Transport page: 16

- Seven Seas Voyager Will Boast Dolphin Podded Propellers page: 18

- Siemens To Supply Fuel Cell Technology page: 19

- IZAR: Hoisting More Than a New Image page: 20

- FORAN V50 Coming Soon page: 23

- Saving the Castor: Critical Issues Must Be Addressed page: 26

- Craft Bearing: On Solid Ground With Split Bearing Solution page: 28

- UMC Opens New Underwater Repair Facility in Portland, U.K. page: 29

- Bollinger Offers N e w Pitch To Ship Repair page: 30

- Titan Is Challenged In Persian Gulf page: 31

- Repair Pipe Leaks FAST W i t h STOP IT page: 32

- Suez Canal Authority O r d e r s Syncrolift page: 32

- Flender Werft Launches Floating Drydock page: 33

- Norshipco, MSC A n d M a e r s k Celebrate Renaming Of MV page: 34

- ASRY Grabs Hold Of UL/VLCC Market page: 35

- UPC Foam Filled Fenders: The Ultimate Protector page: 36

- Atlantic Dry Dock Takes On Tug And Gaming Market page: 37

- H y d r e x Team Performs U n d e r w a t e r W o r k O n S a i p em page: 38

- Raytheon Marine Purchased By Management Buyout Group page: 39

- GE Marine Starts Engineering For Eighth LHD page: 39

- U.S. Tank Barge Market Report page: 41

- Double Trouble? Double Trouble? page: 43

- Scottish Company To Revolutionize Coating Inspection page: 45

- Leading a Sea of Change page: 46

- The Practical Lifeboatman page: 48

- ICS Launches Video Conferencing Breakthrough page: 51

- Using Computer Based Training for STCW Basic Training page: 51

- Furuno Offers N e w GMDSS page: 52

- Austal USA Secures Candies Vessel Duo page: 54

- Samsung Delivers Excellence page: 58