Interview: Dr. Herbert Aly

Shipyard boss Dr. Herbert Aly discusses Blohm+Voss’ radical reorganization as well as the strategies to secure new orders.

When I started my nautical career at Blohm+Voss at the beginning of the early 1960s, one could see on the southside of the river Elbe nine independent operating shipyards. Today only one remains: Blohm+Voss. More than 100 years experience, technical know-how and modern production technology helps to ensure the international global competitiveness of the City of Hamburg as an important site for shipbuilding. The biggest shipyard of Hamburg is Blohm+Voss - an enterprise with more than 135 years of history. The company owns seven docks offering capacities for ships up to 320,000 dwt, including one of Europe’s largest dry docks, Blohm+Voss Dock Elbe 17, with a total length of 352m.

The site belongs to the cityscape like the St. Michael’s church, or the city lake Alster – their history dates back to the year 1877. In the 1920s the shipyard employed more than 10,000 employees – ranking it as the biggest employer in the Free and Hanseatic City of Hamburg. Well-known ships such as Europa, Bismark, Wilhelm Gustloff, Gorch Fock and Cap Arcona – and many others – have been launched here. The shipyard has, during its 135 years of history, experienced and survived many ”ups” and ”downs”. The last ”down” during the worldwide economical crisis in 2009/2010.

Can you please provide a short overview of your career and current position?

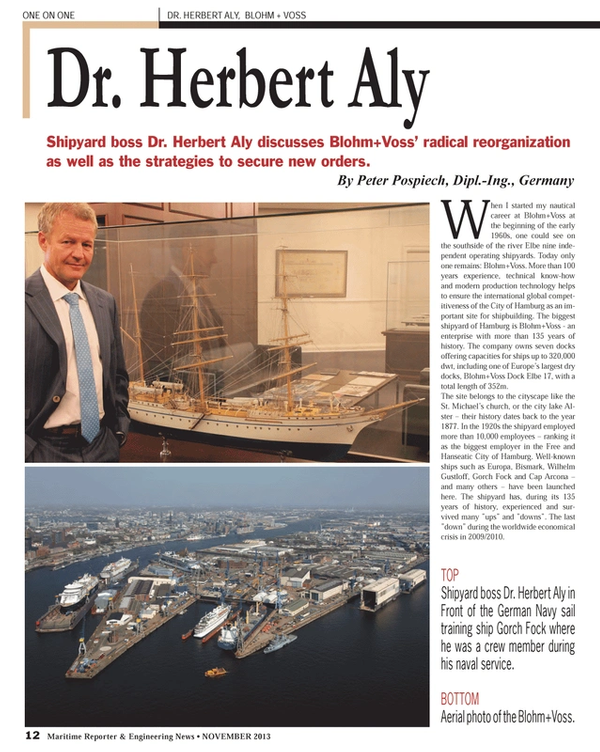

I was born in 1958 and grew up in the Harz region, in the city of Clausthal-Zellerfeld. After graduating from high school I spent 12 years in the German Navy, among others also on the sail training ship Gorch Fock. During this time I completed mechanical engineering studies. After termination of my service in the navy I worked at Blohm+Voss and was responsible for the power plant business. During this time I finished my doctorate on the topic of ”Hydrogen and Energy Economy.” From 1996 on I spent years in different German energy companies. In 2004, I came back to Blohm+Voss and was a member of the board of ThyssenKrupp Marine Systems AG until 2012, and since 2008 Chairman of the Board of Blohm+Voss Shipyards GmbH as well as Blohm+Voss Repair GmbH. After the sale of the civilian shipbuilding activities implemented by ThyssenKrupp Marine System in February 2012 I took over the presidency of both the enterprises, this also under the new ownership as a Managing Partner.

Blohm+Voss is well-known and regarded globally, having built many great ships over the years. What were the reasons for the radical reorganization of the shipyards structure in 2009?

Already before the world economic crisis and under the aegis of ThyssenKrupp Marine Systems, we started with the reorganization in 2008. During that period we realized that merchant ships could be produced at considerably more favorable conditions in Asia than by us – so we needed to direct our attention on special ships in those areas where Blohm+Voss has the knowledge. That were naval shipbuilding and yachts.

The company has a long tradition in the building of exclusive yachts: the very first luxury yacht for cruises were supplied by Blohm+Voss already in 1900 – it was the Prinzessin Victoria Luise. The high product quality is approved, for example the Savarona, built in 1931 and still in service. The requirements in yacht building are essentially different of this in naval shipbuilding. Yachts built by Blohm+Voss are so called “one-offs,” meaning they are built only one time, with a one-off expenditure in design and construction. In the segment of naval shipbuilding ship plans are worked out and the ships are build in small batches. This means, structures in naval shipbuilding are different for processing an order than in yacht building. In the yacht building we adapted our structures on the very specific characteristics and we can react flexibly and fast on a customer’s wishes. An additional difference can be seen in the building location. Naval ships are produced mainly in the principal’s country, whereby yacht customers pay to have their ships built in Germany by Blohm+Voss.

Furthermore, we see with yachts a growing market, which is for Blohm+Voss a suitable ”special ship” segment, where we have a brand which is recognized for quality, exclusivity and manufacturer character. Against this background, the newbuilding segmentation has been done in a naval and a civilian part to venture a comeback in the yacht business.

How does the today’s structure looks like?

After the takeover of the civilian ship building activities by Star Capital Partners as the new owner, basically we have two divisions: newbuild and repair. Blohm+Voss Shipyards GmbH for the complete new building activities and the Blohm+Voss Repair GmbH for repair and modification. Both divisions support each other. The shipyards core business is on the one hand the modification and repair of ships and offshore units as well as the building of premium-segment yachts. At new buildings Blohm+Voss works as a subcontractor for ThyssenKrupp Marine Systems during the next years, among others, on frigate orders for the German Navy.

Which strategies promise success against yards in the Far East?

At Blohm+Voss we will, and this is very essential, concentrate on megayachts. Here we have, as mentioned before, a long tradition. Certainly, we have to anticipate that somewhere in the future also luxury yachts will be built in China (as indicators already suggest). Fortunately customers in this segment still have a substantial brand consciousness. The customer wants to have an upmarket quality product out of Germany – and this is what we offer. Still we have here a technology and brand advantage. That means for us we have to assert ourselve on this particular market with highest quality and excellence.

How is your current order situation?

We have one megayacht in production which is in the outfitting phase. We are shortly to receive an order for another luxury yacht. Furthermore we are working on different yacht projects which are coming into near decision with the customers. With the repair situation we can be absolutely satisfied – our capacity in this regard is being fully utilized. Of course, we cannot look into the future and beg reassured, particularly as the repair sector is too volatile.

If you could make two wishes for Blohm+Voss, what would it be?

First unlimited financial guarantees for our business, because it is for the time being, one of the big problems for the whole branch to receive financing or, as in our case, even refund guarantees for down-payments from banks. Others, such as insurance companies, have to fill the gap. And on the other hand a more steady capacity utilization, in other words: it would be a big challenge for us, if two yacht orders came into the house exactly at the same time which should be processed totally in parallel.

A final private question: how and where does Dr. Herbert Aly relax?

Dr. Aly points towards a large photo on the wall in his office and smiles: ”Look at this, this is my passion. Unfortunately I sail this beautiful schooner very seldom – at least I could make it to sail it 10 days in this year. On top of this, I own a catamaran and dragon on the Alster – if it can be leisurely I use the dragon but with stronger wind I take the cat. But as mentioned: unfortunately I do not have enough time to practice this beautiful sport.

Read Interview: Dr. Herbert Aly in Pdf, Flash or Html5 edition of November 2013 Maritime Reporter

Other stories from November 2013 issue

Content

- Interview: Dr. Herbert Aly page: 12

- Knowledge is Power page: 16

- ReFRESCO: Understanding & Designing Energy Saving Devices page: 18

- Nontank VRP Regs page: 20

- The Magic Ingredients of a Healthy Safety Culture page: 24

- e-Compliance: Revolutionizing the Efficiency of Compliance for Maritime Regs page: 28

- Pull the Handle Down... page: 30

- Return of the Electric Boat page: 38

- Fast Ferry Gets a New Power Package page: 42

- Cat tackles Tier 3 and Tier 4; Completes Berg Deal page: 44

- Konrad, Cummins Propulsion Package Partnership page: 46

- Scania 13L Inline; 16L V8 for EPA Tier 3 page: 48

- The Switch: New Drive Train Tech page: 48

- John Deere Tier 3 Engine Line Up page: 49

- GE Power Conversion page: 49

- EPA’s Vessel General Permit (VGP) & You page: 50

- Are PAGS the Answer? page: 51

- Don’t Forget: Seawater is a Free EAL page: 51

- Lukoil: Cylinder Oil to Reduce Wear, Consumption page: 52

- Agip Rebrands as Eni Powers Ahead in North America page: 52

- Floating Production Systems: Market Update page: 54

- Offshore Brazil: The Libra Field & Brazil’s Pre-Salt Policy page: 56

- On Ballast Water, Time is Running Out page: 60

- Standardization for Safer Shipping of e-Navigation & Training page: 62

- Apprenticeship Training & Academic Degree: The Pathway to Success page: 64

- The Drawing Board: Innovative OSV Design from the Ground up page: 68

- Product Tanker Hijackings page: 72

- The Trinidad & Tobago Maritime Sector page: 74

- Seatorque Boost for Brazil’s Biggest Superyacht page: 76

- Raytheon Anschütz Launches New Gyro Compass page: 85

- Emsys Upgraded to Measure Mass Emissions Rates page: 85

- Thuraya SatSleeve Transforms iPhone into Satellite Phone page: 85

- Kongsberg Debuts New Drilling Rig and Ship Simulator page: 85

- Martek: “BNWAS Password Protection is Essential” page: 85

- Northrop Grumman Radars for USN page: 85

- Imtech Debuts SeaPilot 76 page: 85

- FORAN in Indonesia page: 85

- Raymarine Autopilot page: 86

- Computer Gaming & Maritime Training page: 86

- Jeppesen Updates VVOS Software page: 86

- Harris CapRock & Carnival Sign Contract page: 86

- Carlisle & Finch SmartVIEW Technology page: 86

- Thomas Gunn Unveils New Digital Chart Management System page: 86

- CM-1000 Series: Smart Fluid Handling Tech page: 87

- Paperless Navigation page: 87

- TNKC Fleet & BASS Software page: 87

- Cobham Touchscreen Navtex page: 87

- GE Dynamic Positioning System page: 87

- Ecospeed Fuel Savings Calculator page: 87

- Boatracs’ BTConnect AIS page: 87

- New Brakes from Wichita Clutch page: 88

- Home Study Programs page: 88

- New PowerShark Tool Eats through Biofouling page: 88

- VIKING Expands Training page: 88

- SUPREME Athmos Zero-Pollution Seal page: 88

- New Inertia-Engaged Turbine Air Starter page: 88