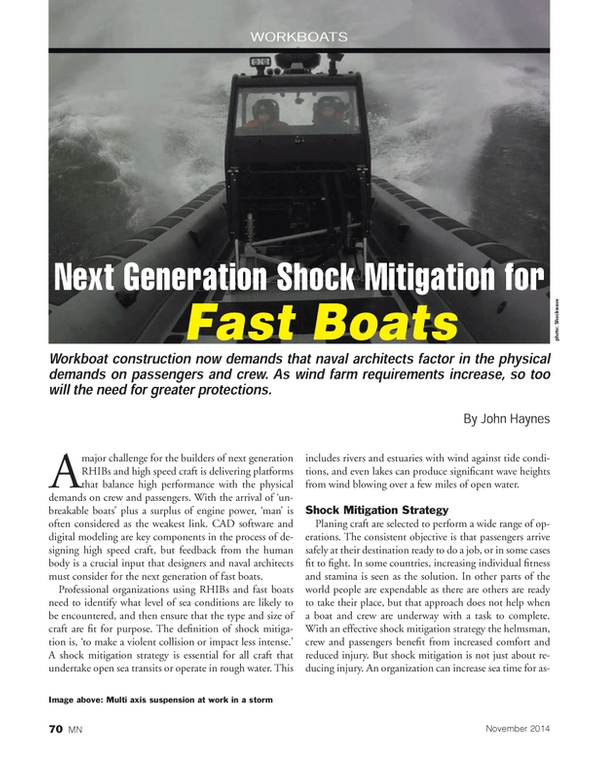

Next Generation Shock Mitigation for Fast Boats

Workboat construction now demands that naval architects factor in the physical demands on passengers and crew. As wind farm requirements increase, so too will the need for greater protections.

A major challenge for the builders of next generation RHIBs and high speed craft is delivering platforms that balance high performance with the physical demands on crew and passengers. With the arrival of ‘unbreakable boats’ plus a surplus of engine power, ‘man’ is often considered as the weakest link. CAD software and digital modeling are key components in the process of designing high speed craft, but feedback from the human body is a crucial input that designers and naval architects must consider for the next generation of fast boats.

Professional organizations using RHIBs and fast boats need to identify what level of sea conditions are likely to be encountered, and then ensure that the type and size of craft are fit for purpose. The definition of shock mitigation is, ‘to make a violent collision or impact less intense.’ A shock mitigation strategy is essential for all craft that undertake open sea transits or operate in rough water. This includes rivers and estuaries with wind against tide conditions, and even lakes can produce significant wave heights from wind blowing over a few miles of open water.

Shock Mitigation Strategy

Planing craft are selected to perform a wide range of operations. The consistent objective is that passengers arrive safely at their destination ready to do a job, or in some cases fit to fight. In some countries, increasing individual fitness and stamina is seen as the solution. In other parts of the world people are expendable as there are others are ready to take their place, but that approach does not help when a boat and crew are underway with a task to complete. With an effective shock mitigation strategy the helmsman, crew and passengers benefit from increased comfort and reduced injury. But shock mitigation is not just about reducing injury. An organization can increase sea time for assets, cover greater distances at higher speeds, improve crew performance and extend operational effectiveness.

It is important to learn from other sectors that have made progress with shock mitigation, but myths need to be dispelled. From motion analysis metrics on land, sea and aircraft, it is clear that not all vehicle impacts are simply lesser or greater G forces. A major difference between automobiles and boats is the suspension system managing vibration between road wheels and the chassis. Trucks take this a stage further and have suspended cabs, so the seat is mainly for comfort. An agricultural or mining vehicle driving over rough terrain experiences different loads to a boat at planing speed on rough water. In recent years, the development of MRAP (Mine Resistant Ambush Protected) military vehicles has accelerated research into reducing the effects of mine blast. However, a vehicle seat that mitigates the shock from a mine blast is unlikely to mitigate the repeated slamming effect from high speed wave impacts.

Aviation has researched shock mitigation and the effect of various impacts. Helicopter seating is designed to protect the crew from hard landings and a crashworthy seat is part of the overall crumple zone. Ejector seats have saved the lives of many pilots and navigators as they exit from fixed wing aircraft. However, ejection is a single event based on a consistent input force, usually initiated by the seat occupant, and compared to loss of life, some level of injury may be acceptable. Large wave slams at sea are not usually isolated events, they can be of random magnitude and from multiple directions. In rough sea transits, the boat suspension seat has a fraction of a second to return from a ‘hit’ to mitigate a ‘double hit’ or the next pattern of multiple impacts.

A core component of fast boat training should be specialist knowledge to educate coxswains and crews to understand the forces that affect a planing craft, particularly when operating in waves. For planing craft there are three conditions to consider – displacement speed, getting on or off plane, and planing speed. When loitering or at slow speed in waves a craft follows the waters surface, the human response is unlikely to be injury but could be motion sickness. An issue with operating at ‘hump-speed’ is that the helmsman has poor visibility over the bow, which can reduce awareness of sea conditions.

Understanding & Quantifying the Forces

To develop the next generation of shock mitigation solutions for fast boats operating in waves it is important to understand the forces that the hull is experiencing as it passes through or over moving and uneven water surfaces. Disturbances could be caused by storms hundreds of miles away generating groundswell, local windblown waves or the wake of other vessels. From an understanding of wave events scientists and engineers can analyze the exposure chain of hull, deck, seat and finally the human body of boat occupants.

Scientists are starting to quantify wave slams and describe how differently a planing craft re-enters the water in various sea states and wave patterns. In simple terms, a fast RHIB or high speed craft can land bow first, stern first, flat on the keel, or on one side of the hull. The process can be filmed and replayed at slow speed or analyzed with data recorders in different sea states. When crews come off the water after a hard transit, the subjective statement of ‘that was a hard ride’ can now be quantified. Two coxswains on identical boats running side by side at the same speed can have vibration measured on each craft for later analysis. Used correctly, this approach is a powerful training tool where video and metrics can show ‘what good looks like.’

Monitoring the effects of vibration and impact on the hull or critical pieces of equipment is relatively simple, as data loggers can be attached to FRP, aluminum or plastic in various ways. Land-based industry has been doing this for years on factory and moving machinery, then developing shock mitigation methods to damp or eliminate vibration by tuning the dampers. Measuring the forces on the deck or on a seat base will produce data, but a topic of major debate in recent years has been how to gather vibration data from the crew and passengers. The lower back is the area with highest incidence of injury, however fixing accelerometers to a flexible human body is difficult. Seat pads and kidney belts are common methods that provide reasonable contact for data loggers. The consistent objective is valid and reliable measurement for the assessment of RS (Repetitive Shock) and WBV (Whole Body Vibration).

As the cost of data loggers has come down various organizations around the world have started to gather and store vast amounts of vibration data. Analyzing the data and deciding which metrics are relevant is a challenge. A simple Red Amber Green (RAG) index showing traffic lights on the console is an indicator to show crews that vibration exposure is increasing. However, setting the vibration thresholds for color change may vary depending on which measuring method is used.

Seating Solutions Evolve

As the fast boat sector has evolved over the past decade, the diversity of potential seating solutions has grown with it. RIB and high speed craft seats need to provide a good ergonomic position for the different requirements of helmsman, crew and passengers. Comfort is important so seating design needs to allow space for occupants PPE and personal floatation devices. Some organizations require webbing and body armor to be worn and weapons to be carried. This may require an adjustable seat with built in personal storage for equipment.

For the past thirty years typical seating for RHIBs and fast craft has been jockey (straddle) or leaning post with foam cushioning. Due to higher operational speeds many organizations are now using or considering suspension seating. The objective of a suspension seat is to separate the helmsman and crew from the worst effects of vibration and impact. Suspension seating may have feet on or off the deck. A jockey suspension seat is where a percentage of the occupant’s weight is spread between backside on the seat and feet on the deck. Typical stroke or travel of the suspension is 6” (150mm) to prevent bottoming out. The next generation of seats have the option to adjust for height and weight which allows for a broad size range of occupants. This adjustment has to be supported with clear instructions and onboard briefing as a badly adjusted seat can be an issue.

A conventional suspension seat with feet on footrests carries all of the occupant’s weight. Suspension travel for semi-displacement craft seating starts around 4” (100mm). For extreme fast craft, the travel can be over 8” (200mm). It is becoming increasingly relevant to either select the correct seat for the boat or tune the seat to the boat. In rough conditions the seat is the only part of the boat that humans can travel on so increasingly workstations will be attached to the seat.

The European wind farm sector is driving higher levels of safety for crews and technicians being transported on planing craft. Crash testing for individual seats and deck fixings is relevant for craft operating in close proximity to wind turbines and other vessels. Improved ergonomics and adjustments are required for these seats as passengers are expected to travel further offshore in higher sea states for longer periods. Varying body position during a long journey is important on any mode of transport. When the seat occupant is asleep the whole body needs to be suspended to enable the suspension to do the work. Research is considering whether a recumbent or reclining position is more comfortable and gives better spine protection when conscious bracing is not possible.

The Way Forward

Linking the man or woman to the task is becoming a requirement for many military and Special Forces organizations. As seat and suspension systems evolve more responsive controls and work station layouts with improved ergonomics are part of human factors design. Helmsmen already have joystick steering and throttle controls built into the armrest of their seat. Navigators can only work effectively at high speeds if their GPS and radar screens are moving in unison with their hands and eyes. Communications, situational awareness and weapons technicians benefit from control panels attached to their seats. Gunners operating at high speeds require specialist suspension seats attached to weapons.

In recent years, there have been significant developments in the fast boat sector. Major steps forward in technology by seat manufacturers may mean that ‘man’ is not always the weakest link on fast boats. Boat speed on flat water is governed by the power limit but speed in waves may be governed by the structural design limit. Professional fast boat coxswains generally operate to a level known as tolerable discomfort, then the pain threshold is reached and they are likely to slow down. But as innovative suspension systems have de-coupled the man from the boat the new challenge is to build hull, components and equipment that are able to survive the extreme ride severity that occupants can now tolerate.

To support procurement decisions the next generation of fast craft hulls and shock mitigation solutions need to be compared. Full scale sea keeping trials in high sea-states are costly, weather dependent and will vary between craft. Wave conditions are rarely consistent over sea areas or over time. It is also hard to justify taking people to the point of injury as part of testing. To address this, an International Standards Organization (ISO) Technical Committee Working Group was established in December 2013 to develop standard procedures for ‘Laboratory evaluation of marine seat shock isolation.’ Preliminary drop testing has been performed in the UK and Canada in to demonstrate seat mitigation characteristics in the lab before installation on boats for on water testing.

Overall, the fast boat sector now has a better understanding of the problems associated with high speed transits. Commercial, energy, emergency, government and military organizations all need to recognize that a shock mitigation strategy needs to be incorporated into design, training, planning and operations. Other technical shock mitigation solutions include innovative hull forms to improve ride quality, hull appendages to control angle of attack in waves and cushioned decks for crew and passengers to stand on. Even with all this technology, important factors for individual mission success and long term capability all depend on how an organization takes care of passengers and the skill of the coxswain to drive according to the sea conditions.

John Haynes is an Associate Fellow of The Nautical Institute, Yachtmaster Ocean and Advanced Powerboat Instructor. Subject matter expertise includes high speed craft consultancy, product development and specialist training. He is Managing Director of Shock Mitigation and founder of the RIB & High Speed Craft Directory that brings together specialist boats and equipment for the sub IMO / sub 24 meter professional sector. www.ribandhsc.com

(As published in the November 2014 edition of Marine News - http://magazines.marinelink.com/Magazines/MaritimeNews)

Read Next Generation Shock Mitigation for Fast Boats in Pdf, Flash or Html5 edition of November 2014 Marine News

Other stories from November 2014 issue

Content

- Insights: Morton S. Bouchard III page: 12

- Energy’s Promising Future Threatened page: 20

- How Difficult is it to Obtain a Jones Act Waiver? page: 24

- Shipbuilding Regulations: Cents and Sensibility page: 28

- Night Moves on America's Waterways page: 32

- Choosing the Best Financing Proposal page: 36

- WRRDA: Clearing the Channel for P3 Projects page: 40

- Marine Noise Emissions: Is it Your Next Regulatory and Environmental Hurdle? page: 52

- An Open Arctic and its Impact on Oil Drilling page: 58

- Experience Counts in the Arctic page: 66

- Next Generation Shock Mitigation for Fast Boats page: 70

- Future LNG Exports to Impact Traffic, Tug Requirements page: 76

- USCG Credentialing and Mariner Medical Evaluations page: 82

- Marine Lubricants Engineer Solves Problems page: 86

- Proper Applications for Specialty Lubricants page: 90

- Fugitive Emissions: The New Regulatory Elephant in the Room page: 94

- Making a Conscious Change: Seaspan Marine’s Conversion to EALs page: 100

- Safeguarding GPS When Global Positioning Doesn’t Work page: 104

- Fort Ripley: Multi-Missioned & Fully Capable page: 107

- PalmScope Video Inspection System page: 120

- New Hydraulic Lifts from J D Neuhaus page: 120

- BRP to Install Evinrude E-TEC Engines page: 120

- Introducing the All-new MJP Hybrid page: 120

- Tier 4 Final Gensets from Cummins page: 120