Where Failure is Not an Option

Naval vessels cannot afford to lose critical systems following an impact. Brian Stanton, North America Engineering Lead at Parker Hannifin's Gas Turbine Division, talks about the extensive testing required for inlet filtration systems used on these ships.

Inlet filtration used for critical ship systems, such as on the propulsion gas turbines, must pass rigorous testing prior to installation. These tests include a range of vibration and shock tests that simulate ship operation and test the working of the system in the event of an impact or explosion.

Vibration testing

Navies have standards for vibration testing. In the U.S., for example, MIL-STD-167-1A details requirements for US Navy vessels to ensure equipment remains reliable with vibration from the engines, propellers, and other onboard systems. It details a testing range of 4-33 Hz, although a specific vessel may only require a smaller range.

Testing begins with an exploratory phase whereby equipment is fixed to a vibration table and testing at each frequency for a brief, 15 second interval. This helps establish that there are no obvious problems before more in-depth testing commences. At lower frequency ranges, the test table uses higher amplitudes, and at higher frequencies, lower amplitudes.

The table is then adjusted to run each frequency for a period of five minutes. Based on readings from accelerometers, the endurance test frequency or frequencies will be established. If the accelerometers show no suspect areas across different amplitudes, the highest range is selected and run for an extended test period of two hours. If there are two ranges that appear to cause vulnerability, each is run for one hour. If more ranges require extended testing, they run for 40 minutes each. After two hours (or longer if more ranges require investigation), the engineer can confirm whether the equipment has any issues that require remedial work. If this is the case, testing will need to be repeated. Hopefully, the shorter tests at the beginning of the test cycle will help to ensure any suspect areas are identified and corrected before the longer testing cycles.

Shock testing

On successful completion of vibration testing, equipment is prepared for shock testing. These tests, which in the U.S. are covered by the MIL-DTL-901E standard, are designed to ensure ships will remain in operation even after an explosive impact.

Testing is broken into three ranges: light, medium and heavyweight. Smaller tests use a hammer with adjustable height and weight. The equipment is fastened to a plate, which is struck by the hammer to simulate small shocks. The orientation of the test table is varied according to the class of equipment and how it will be mounted onboard, with hammer strikes at three different heights at up to three orientations.

Medium shock testing uses a bigger hammer with more height options. The hammer height is adjusted according to the overall payload required and size of the equipment. Again, different impact orientations are tested.

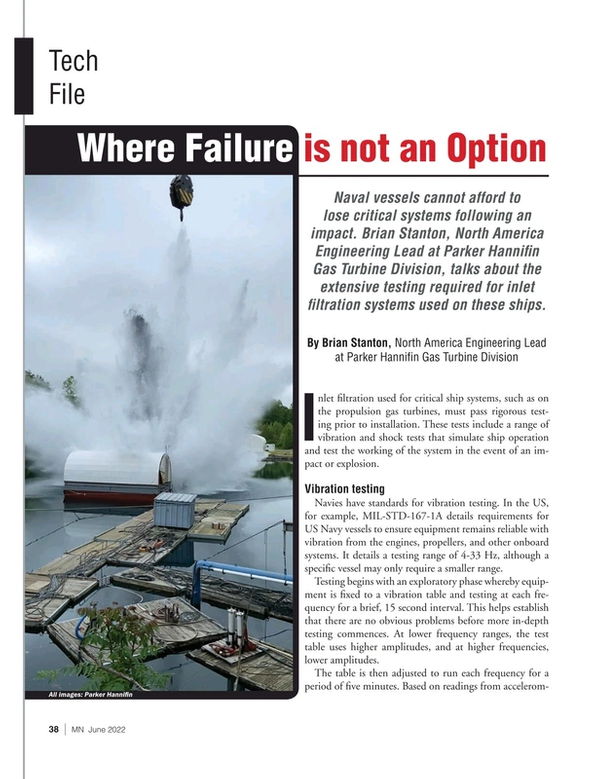

More payload is needed for heavyweight testing. The equipment is rigidly mounted on a baseplate or loading arm on a floating barge, with orientation depending on where it will be fitted to the ship, whether that be on the hull, deck, or an internal section. An explosive device is used to simulate impact and is sited at relevant distance away from the barge. The depth in the water is also varied according to the size of the charge, with greater depths used for higher charges.

Blasts are set to impact across and in line with the ship. The in-line explosive is set furthest away and is generally the last test to be carried out as it is the least destructive and the easiest to pass, enabling modification to be made if required from earlier tests to avoid having to carry out the complete test suite again if problems arise. Lateral explosive tests are set to get progressively nearer the barge.

Summary

Vibration and shock testing is vital for inlet filtration systems as these are essential to ensure reliable operation and the ability for the ship to get back to a safe place where damage can be repaired following an explosion or event. Parker filtration systems are used by various navies throughout the world with the surety that they will continue to operate and keep the vessel operational when in combat.

Understanding and designing systems to withstand shocks and vibrations are fundamental to the supply of onboard systems. Testing is complicated, with many different aspects covered to ensure it reflects the diversity of potential issues in real-world operation.

Parker has the in-house expertise to support naval applications and its equipment has a proven track record for performance and reliability in the harsh conditions vessels may be exposed to.

Read Where Failure is Not an Option in Pdf, Flash or Html5 edition of June 2022 Marine News

Other stories from June 2022 issue

Content

- Interview: Johan Inden, Volvo Penta page: 12

- How to Choose Propulsion Systems for Patrol Craft page: 18

- Updates, Developments and Advances in Combat and Patrol Craft page: 22

- Maritime Communications: Easier, Faster, Cheaper page: 28

- SAFE Boats: Keeping ’Em Coming page: 34

- IMTRA: Growth from Within page: 36

- Where Failure is Not an Option page: 38