Inland Waterways: US Making Progress on Infrastructure

The United States’ vast network of navigable inland rivers is vital to the nation’s economy, serving as an aquatic superhighway for the efficient shipment of critical commodities like agricultural goods, energy products, building materials and industrial chemicals to destinations within the U.S. and to deepwater ports for export. The Waterways Council, Inc. (WCI), which advocates for a modern, efficient and well-maintained inland waterways, often describes the network as “the backbone of the transportation logistics system”.

But much of the waterways’ critical infrastructure—including locks and dams that are vital to maintaining navigable rivers and enabling the efficient flow of commerce—are in desperate need of maintenance and repair, or in many cases, flat-out upgrade. So WCI engages with industry and policymakers to help secure the funding that will move these waterways projects along, and ultimately improve the efficiency of the system at great benefit to the nation.

Breaking ground

In August, the U.S. Army Corps of Engineers Pittsburgh District held a groundbreaking ceremony at the Montgomery Locks and Dam facility to kick off the Upper Ohio Navigation Project, part of the National Economic Development (NED) plan for improving the Emsworth, Dashields and Montgomery locks and dams with new expanded lock chambers. At each of the three sites, the auxiliary lock chambers, currently 56 feet wide by 360 feet long, will be replaced with new 110- by 600-foot lock chambers that will serve as the new main.

The fully-funded, total project cost for all three new chambers is $2.1 billion, which would be cost-shared jointly by the General Fund (65%) and the Inland Waterways Trust Fund (35%) (2021 Cost Level). Congress authorized the Upper Ohio Navigation Project in the Water Infrastructure Improvements for the Nation (WIIN) Act of 2016 (P.L. 114-322). A big boost came via the Bipartisan Infrastructure Investment Bill of 2021, which included $857 million for Montgomery construction and $77 million for Emsworth.

The BIL funded the district for about half of the required Montgomery cost up front, shortening the Corps’ construction timeline significantly. Design work for Montgomery’s new lock chamber is underway, and the first preparatory construction contract for Montgomery lock was awarded in 2020. The Corps said additional preparatory contracts are planned, and that it anticipates awarding the contract for new lock chamber construction in 2024.

“It’s taken over a decade of dedicated effort from an interdisciplinary team to get us here today,” said Colonel Nicholas Melin, who recently took over as USACE Pittsburgh District commander. “This team has developed and delivered a solid plan that we are now ready to execute.”

The Corps’ plan includes removing the auxiliary chamber to expand the lock size, which will cut into the gated dam currently on the river. The new lock at Montgomery will require about 400,000 cubic yards of concrete, or 1.6 billion pounds. Steve Fritz, the Mega Project program manager for the Pittsburgh District, said a batch plant will soon be brought on site, allowing concrete to be mixed and poured in place in a more efficient manner. The plant will produce nine different concrete mixes used in various types of construction, such as underwater, structural and mass concrete, among others, Fritz said. An onsite laboratory will sample and test the concrete to ensure quality.

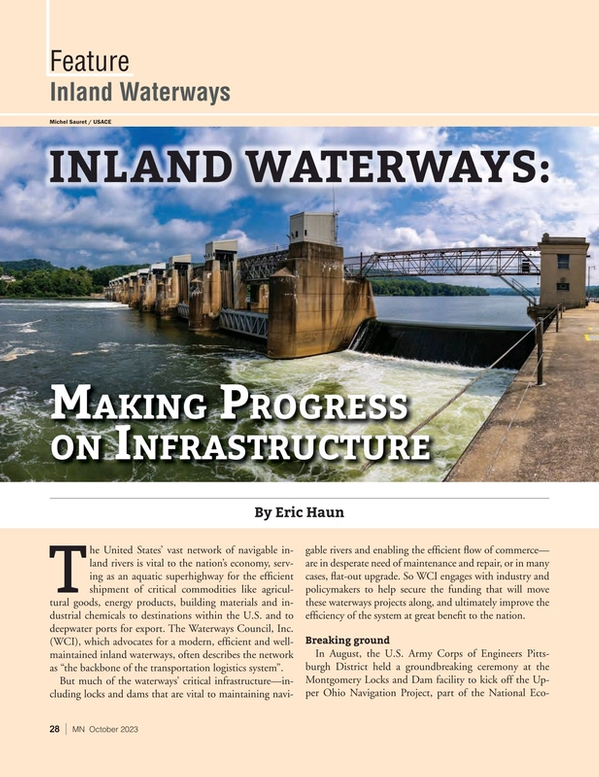

Montgomery Locks and Dam on upper Ohio River (Photo: Michel Sauret / USACE)

Montgomery Locks and Dam on upper Ohio River (Photo: Michel Sauret / USACE)

According to the Corps, the groundbreaking “sets the stage for updating the Ohio River’s oldest navigation system”. Emsworth, Dashields and Montgomery—the first three locks and dams on the Ohio River downstream of the Point of Pittsburgh—were each constructed prior to 1936 and have the oldest and smallest lock chambers on the Ohio River.

Of course, replacing old infrastructure with new has its obvious benefits, but the new larger lock chamber will also boost efficiency by allowing operators to pass through with larger tows. “The upgrades we are making at Montgomery Locks and Dam are just the first of three major investments to modernize the upper Ohio River navigation system,” Fritz said. “We are building larger, newer, better locks that will provide a resilient navigation system in the Pittsburgh region for the next 100 years.”

Desperate need & vital importance

The auxiliary lock at Montgomery has reached the end of its operational lifespan and is experiencing structural aging, according to Chris Dening, the project manager for the construction of the Upper Ohio project. “Many of the walls have significant cracking along and across their lengths. We have observed leaking within the lock walls during operation, which confirmed the seriousness of the situation,” he said.

The Upper Ohio navigation system sees 15 to 20 million tons of materials pass through its river chambers annually, according to the USACE. If one of the lock walls at Montgomery failed, it would impact operations for several months, leaving shippers scrambling to find new ways to reroute shipments. A one-year closure at Montgomery Locks and Dam would cost the U.S. economy nearly $180 million, the Corps said.

Dening said the Pittsburgh District is working to avoid sudden failures through more frequent engineer inspections and noted that contingency plans have been developed for potential emergencies. “Those contingency efforts are costly, which is why we need to recapitalize the lock with a new construction,” he added.

Maty Hettel, vice president of government affairs at American Commercial Barge Line (ACBL) and a member of the Inland Waterways Users Board, said the barging industry ranks Montgomery among priority river infrastructure projects. “The way our capital investment strategy is put together, we rate these projects on risk of failure and value to the nation, and certainly this one’s got a big risk of failure with that center wall subject to possible failures. If we lose that center wall, needless to say, we can lose this whole pool, which would shut down navigation,” he said.

Hettel noted that it’s crucial the project be funded to completion and that the Corps be able to stay on schedule to finish the job on time, referencing other projects such as the Olmsted and Kentucky Lock projects that have been drawn out over several decades. “The timeframe to build these projects has got to stay shortened; as they used to say, move it to the left as much as they can. We understand it takes a long time . . . but we don’t need to fall in that scenario with these other projects. Hopefully we have the labor, and the Corps can finish this in 10 years as they plan.”

Peter Stephaich, chairman and CEO at Campbell Transportation Company, Inc., said his company is probably the largest user of the Upper Ohio system and that the completed upgrades would improve reliability significantly.

“We won’t have to suffer all the delays; this lock [Montgomery] has been closed to required maintenance many times,” Stephaich said. “Earlier this year, we were waiting 10 days with fully crewed boats on either side to try to get through here, which is extremely disruptive and extremely expensive. We don’t get paid for that time. It has cost our company directly millions per year having to deal with these delays.”

“We look forward to the day that we have not just a groundbreaking, but a ribbon cutting when we’ll be able to achieve the full benefits of this system,” Stephaich said.

Mary Ann Bucci, executive director at the Port of Pittsburgh, described the locks as the river gateway for commerce moving in and out of the city. “If any of these locks, starting with the Montgomery, should shut down, we would lose the entire pool for the entire district, and commerce wouldn’t move; that would be detrimental. And for all the freight that’s moving through these locks and dams, there’s trucks that aren’t on the road. It’s lesser emissions, it’s a safer mode of transportation, and it gets all the cargo delivered to where it needs to be. So, improving this infrastructure is very important.”

Austin Davis, the Lieutenant Governor of Pennsylvania; Col. Nicholas Melin, the commander of the U.S. Army Corp of Engineers Pittsburgh; U.S. Sen. Bob Casey of Pennsylvania; Jaime A. Pinkham, the Principal Deputy Assistant Secretary of the Army for Civil Works; Mitch Landrieu, Senior Advisor to the President and White House for Infrastructure; Mary Ann Bucci, the executive director of the Port of Pittsburgh Commission; and Mark Gentile, the president of Trumbull Corps; participate in a groundbreaking ceremony at Montgomery Locks and Dam in Monaca, Pennsylvania, Aug. 11, 2023. (Photo: Michel Sauret / USACE)

Austin Davis, the Lieutenant Governor of Pennsylvania; Col. Nicholas Melin, the commander of the U.S. Army Corp of Engineers Pittsburgh; U.S. Sen. Bob Casey of Pennsylvania; Jaime A. Pinkham, the Principal Deputy Assistant Secretary of the Army for Civil Works; Mitch Landrieu, Senior Advisor to the President and White House for Infrastructure; Mary Ann Bucci, the executive director of the Port of Pittsburgh Commission; and Mark Gentile, the president of Trumbull Corps; participate in a groundbreaking ceremony at Montgomery Locks and Dam in Monaca, Pennsylvania, Aug. 11, 2023. (Photo: Michel Sauret / USACE)

Read Inland Waterways: US Making Progress on Infrastructure in Pdf, Flash or Html5 edition of October 2023 Marine News

Other stories from October 2023 issue

Content

- Insights: Blaine Dempke, CEO, Markey page: 10

- The Headwinds of US Offshore Wind Development page: 15

- Diverse Resources in Desperate Times page: 20

- Making Hydrogen Work: Demo Project in San Francisco Port page: 22

- Inland Waterways: US Making Progress on Infrastructure page: 28

- Offshore Wind: Support Vessel Bottlenecks Loom in the US page: 32