Bollinger Builds

Bollinger Ramps Up for GOM Oil Sector and Builds for USCG

Lockport, La.-based Bollinger Shipyards, Inc. is humming with work from oil and gas companies and government agencies. Family-owned and operated, Bollinger has 10 shipyards -- nine in south Louisiana and one in Texas -- along with 28 drydocks and 3,000 employees in four administrative locations. Last month, we caught up with Ben Bordelon, Bollinger’s Executive Vice President of Repair, for his outlook on the firm and the Gulf of Mexico. Bordelon is the nephew of Boysie Bollinger, who has been at the helm as CEO since 1985.

“Roughly 50 percent of our business is new construction and 50 percent is repairs,” Bordelon explained. “Government new construction accounts for about 35 percent of our business, and commercial work related to oil and gas provides 50 percent.” Bollinger is the largest vessel-repair company operating along the GOM. The company designs and builds military patrol boats, ocean-going barges, offshore oil support vessels, liftboats, tug boats, rigs, inland push boats, barges and varied steel and aluminum products.

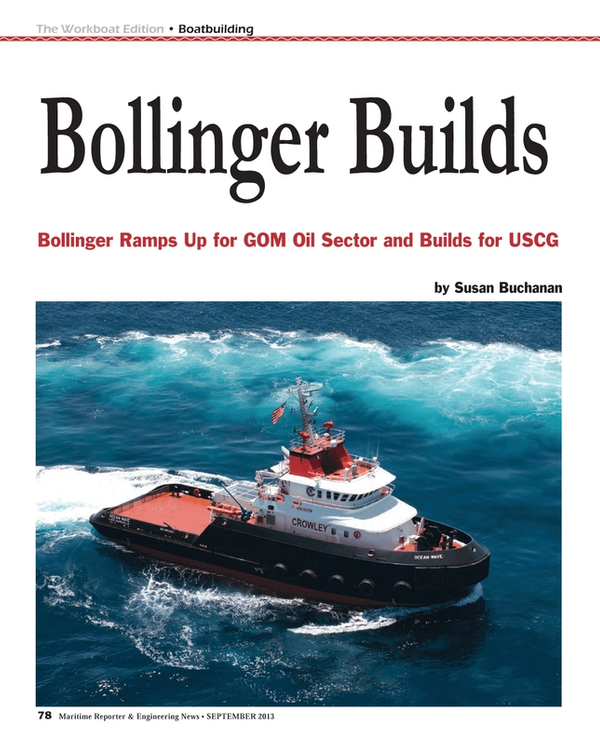

Bordelon said capacity is tight within the shipbuilding industry now. “Coast Guard projects are keeping us very busy in Lockport,” he said. “Our Morgan City facility recently delivered four ocean-class tugs for Crowley and a floodgate for Terrebone Parish. We’re currently building three sludge ships for New York City. We’re also building four 300’ class platform supply vessels.” Crowley Maritime Corp. is based in Jacksonville, Fla.

At Lockport, “we just delivered our seventh fast-response cutter, the Charles David Jr., to the Coast Guard,” Bordelon said. “We have a total of 18 FRCs to build, and expect future awards to add to that contract.”

As busy as its employees are, Bollinger will accept work that fits into it schedule. “We’re currently considering and reviewing additional opportunities,” Bordelon said.

Repeat Customers

As for Bollinger’s clients, “with 68 years in the business, we have a lot of great customers and a lot of repeat customers, going back to my grandfather,” Bordelon said. “They range from the USCG, one of our very best, to oil and gas companies, which are tops for us.”

“The needs of our customers range from deepwater jack-ups to offshore tank barges and inland water vessels,” he said. “Our broad customer base has been key to our success in this business over the years.”

Asked about the contribution of inland push boats and barges to earnings, Bordelon said inland waterways are a significant, mature segment of the company’s business from a customer and vendor standpoint. “They’re a vital part of our repair and propeller work,” he said. “We have a large customer base operating on the Mississippi River and the waterways, served by our machine and hydraulic shops and propeller services.”

Transportation on interstate waterways is crucial to the nation’s commerce, he noted. Bollinger’s shipyards and drydocks, located between New Orleans and Houston, have direct access to the Mississippi River, Intracoastal Waterway and the Gulf of Mexico.

Presence at Port Fourchon Grows

Bollinger has invested heavily in Louisiana’s Port Fourchon. “Fourchon was an emerging port 15 years ago,” Bordelon said. “Our facility there has expanded from a small, topside shipyard with 20 people 12 years ago.” Bollinger Fourchon is now a full-service repair operation, with 1,550 feet of bulkheaded waterfront, providing access for deep-draft vessels and an area for jack-up rigs that can do hull and leg repairs and extensions. “We currently have two drydocks in operation at Fourchon, working 24-7, with between 125 and 175 employees,” Bordelon said. “We’ve listened to our clients’ needs and are expanding. We’ve taken on an additional 47 acres of property in the port’s Northern Expansion area, and will add larger drydocks to our existing drydocks. We will accommodate bigger supply boats and IMR vessels. We’ll be able to drydock vessels up 11,000 tons.”

Also at Fourchon, “we’re expanding and/or adding to our machine shop services, fabrication building, warehousing, propeller repairs, hydraulic services, offices and armature services,” he said. “We’re making a significant investment to better serve our clients. Our new area is in the engineering/bidding phase and will be in full service in 18 months and possibly sooner.”

Port Fourchon is the nation’s busiest oil and gas support terminal.

Offshore GOM Looks Promising

Bordelon is optimistic about the GOM’s oil and gas sector. “We’re seeing lot of positive indications now,” he said. “Our facilities are supplying a widely diverse customer base. We see some legs, some sustainability, with major investments in deep water and shallow plays and also in oil-and-gas drilling on the land side. It all fits together, offshore and land. It’s an exciting time.”

Asked whether Gulf offshore drilling will return to pre-Macondo levels soon, Bordelon said yes. “It’s happening now with deepwater and jack-up activity,” he said. Bollinger expects to supply more vessels to the GOM’s deep than shallow waters this decade, he also said.

As for the GOM’s post-Macondo bureaucracy, Bordelon said rule making after the federal drilling moratorium ended in October 2010 was sometimes difficult to understand. “But we’ve seen more clarity on regulations and the explanations about them recently. We know the new environmental rules that we have to follow. We now know where we’re headed.”

Cutter Contract with USCG Could Grow

Bordelon said Bollinger has been fortunate not to have been affected by federal budget cuts. “But it’s something we’re monitoring closely,” he said. “The cutters we’ve built have been a successful program. We’ve delivered on schedule, the Coast Guard has been very happy with the vessels and we think our contract will be expanded.” The USCG desperately needs more patrol vessels, he said.

When asked about the status of a federal, patrol boat lengthening suit against Bollinger, Bordelon couldn’t comment since it’s ongoing litigation. The suit, filed in July 2011, charges that Bollinger, under a Coast Guard contract to increase the length of eight patrol boats, delivered vessels that were unseaworthy. The hull on the first-delivered, restructured vessel buckled.

Building on Recent History

Bordelon was asked about management changes within Bollinger. “We haven’t really had any major leadership changes recently,” he said. In addition to President, CEO and Chairman of the Board Boysie Bollinger, the management team includes Christopher Bollinger, Executive Vice President of New Construction; Ben Bordelon; and Andrew J. St. Germain, Chief Financial Officer and Treasurer.

Founder Donald Bollinger retired in 1989 and passed away in 2001. The company considered going public in 1997 but decided against it when GOM oil exploration slowed for awhile. Shortly after his father’s death, Boysie made an ambitious acquisition, paying $80 million in cash for five ship and offshore-platform repair yards from Friede Goldman. After that, Bollinger swelled into one of the largest ship repairers in the nation.

Future Plans

What is Bollinger investing in today for its tomorrow? “The easy answer is in brick, mortar and drydock facilities,” Bordelon said. “But a huge component of our future is understanding the prospective needs of our clients.”

“And our workforce, as our most important resource, is an ongoing investment,” he said. “We’re focused on recruiting, training and developing staff. We’re working with colleges, vo-tech schools, high schools and trade organizations to attract good employees.” The company is hiring at all levels and from around the nation. “Safety, a major part of our training, is a critical investment,” he also said.

Bordelon said labor is tight in coastal Louisiana because of offshore oil and land drilling and workers having headed off to shale plays. “But lots of opportunities exist for people who want to learn a marine trade,” he said. “And we believe our employees have benefited from our internal growth and our multi-facility operations. During our 68 years, our people have allowed us to stand out among our competitors.”

(As published in the September 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)

Read Bollinger Builds in Pdf, Flash or Html5 edition of September 2013 Maritime Reporter

Other stories from September 2013 issue

Content

- Shale Oil Is it a Threat to Future Deepwater Development? page: 12

- ZF Marine Propulsion Systems page: 14

- Interview: MAN Diesel & Turbo Head of R&D, Søren H. Jensen, page: 18

- Efforts continue to improve the Modeling of Thrusters page: 24

- GPS Spoofing and the Potential Perils to Ships at Sea page: 26

- Mitigation of Shock & Vibration on Fast Boats page: 30

- LNG Capital Expenditure page: 34

- Safety in Numbers page: 38

- Poland’s Maritime U. page: 40

- Back to School page: 48

- Pick Me Up page: 52

- Liebherr Wins Significant Ship Crane Order page: 54

- BAE Yards Busy with PSV Newbuilds, Ship Repairs page: 58

- The Ties that Bind page: 60

- Floating Production Systems: A Big Opportunity for Shipyards page: 62

- Kirby Corp. CEO Joe Pyne is "No Ordinary Joe" page: 68

- Bollinger Builds page: 78

- Conrad Shipyard: Strength in Diversity page: 82

- SCANIA Powers Ahead in Workboat Market page: 84

- MAN Diesel & Turbo and the Tier-III Age page: 86

- Offshore Service Vessels page: 94

- W&O Expands Repertoire page: 98

- Tech Profile: Colfax CM-1000 page: 102

- A “Look Under the Hood” page: 106

- Beier Radio page: 108

- Carnival to Develop New Emission Reduction Tech page: 110

- Fire Protection for LNG-fueled Ships page: 118

- A Shipyard First Bug-O System’s Heavy-Duty MDS and Hardcoat Anodized Rail page: 120