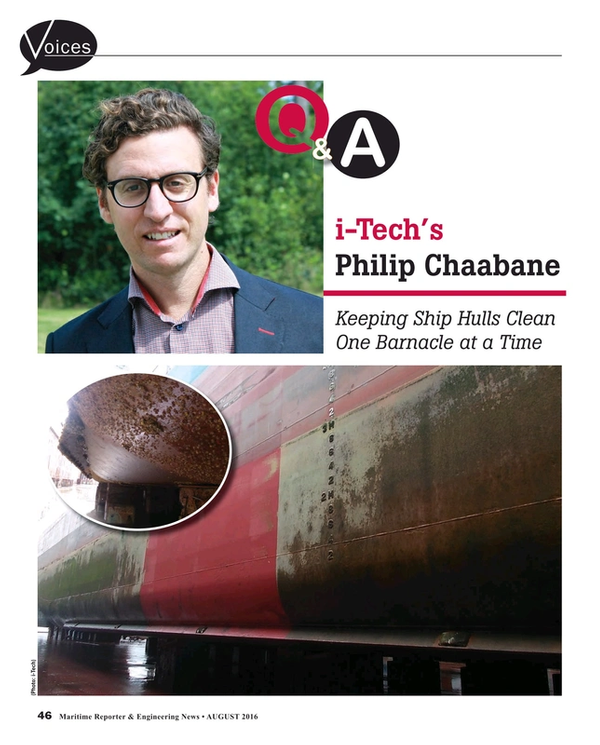

Keeping Hulls Clean One Barnacle at a Time

i-Tech's CEO Philip Chaabane is intent on keeping hulls clean, one barnacle at a time.

Please provide a brief personal/professional background, with insight on how you’ve come to occupy the CEO seat at I-Tech.

I have a Swedish and French MSc in Engineering and have spent some six years in the aerospace industry working for Volvo Aero (today GKN) with jet engine components within product development as well as production and supply chain in general. Robust long term business plans and rigid big corporate structures were in 2009 shifted to a start-up company in the fuel cell industry (Powercell AB) with very few bits and pieces in place for the thrill of exploring new territory. Among a lot of other duties, I practiced the customer development process which really caught my interest. This was the basis also for joining I-Tech who was searching for this kind of skills to take the next steps in commercializing the project. In addition, I had had no exposure to the shipping or coating industry before and was exited to, besides the aviation and trucking industry, get a chance to learn this truly global industry. When the owners decided to refocus from regulatory research focus to market and industrial focus I got the chance to assume the position as CEO in late 2013. Since then we have been fortunate to develop the heritage into strong commercial growth and we now spend most of our time around sales and supply chain matters.

For our readers not familiar with I-Tech, please provide the “50,000 ft.” overview of your company and its offering to the maritime market.

I-Tech is a bio-tech company relying on unique discoveries within the combined domains of pharmacology, marine-biology and chemistry. The result is a patent solution to a problem mankind has tried to solve in all kind of ways since seaborne trade started, namely a robust and sustainable prevention of barnacle settlement on marine structures and vessel hulls. Although sharp improvements have been made within the industry, the way I-Tech addresses the problem generates ways to rethink the traditional concepts of antifoulings using high enough loadings to create a lethal level (towards marine organisms) of concentration at the surface.

I-Techs product Selektope does it differently. It uses not more material than what is absolutely necessary to create a repellant mode of action and it is highly specific minimizing potential effects on other organisms.

Selektope: Self-described as a ‘breakthrough’ in marine anti-fouling technology. Please briefly describe what exactly Selektope is.

Selektope is an organic compound designed for use as an antifouling agent against barnacles. It is compatible with the major antifouling coating systems and has earned regulatory approvals on all key markets for ship repairs and new building. Incorporated in paints, Selektope delivers unrivalled performance towards animal fouling including enhanced static performance. It is flexible enough to allow for many different combinations with alternative substances and it is powerful enough to fully replace cuprous oxide. Both types of formulations are on the market already. Taking full use of Selektope, it significantly reduces the biocidal loadings in paints reducing the emissions to sea. To find suitable compounds to combat marine biofouling is a huge challenge, even more so to find a compound with a suitable efficacy spectra as well as a regulatory and technical compatibility. This is why only three compounds are available to the global industry and why Selektope is a breakthrough technology as it is the first ever relying on a repellant mode of action.

Interesting indeed. How, specifically, does It work?

Selektope is designed to stimulate the octopamine receptor of barnacles triggering a swimming behavior forcing them to leave the surface. By having Selektope available at the surface of a coating any barnacle larvae will be unable to settle at that surface due to the kicking behavior. The effect is reversible and the larvae regains its normal properties. This pharmacological mode of action is effective at nano-molar concentrations (meaning around 300 times lower than traditional technology).

As it is an ingredient in marine coatings, we’re assuming that you are working direct with coatings manufacturers to have this element added. Specifically update our readers on where they can find Selektope today?

Selektope is offered to all coating manufacturers and several are well progressed in their development and final verification work. In the forefront is Chugoku Marine Paints (CMP) who has three products on market (two regionally in Japan (Sea Premier Plus-series), one aiming for the Korean newbuilding market (SeaFloNeo S Premium). There is also a beta-version of a very promising antifouling product (Premium AF-S) from CMP for the global ocean going (dry docking and newbuilding) market being tested on full scale. We are facing very interesting years ahead of us although we hoped things would move a lot quicker in this industry.

Have you run into resistance? If so, can you classify the reasons a company may not want to add Selektope to their product …and discuss how your team has worked to overcome these objections?

A high priority for us is to work as close as possible with the various development teams to quickly understand the eventual issues and support the efforts in overcoming these matters. They are different for each customer but one example is the handling procedures in the factory environment where we have several solutions available to assure all HSE aspects are met and exceeded. Like some other compounds in the industry, the handling has to be carefully controlled and thanks to the very small quantities (a few kg per 1,000 liter of paint) the handling matter can be addressed in unique ways.

Ultimately, what are the benefits of having Selektope for the coatings manufacturers?

- It gives more power to meet the increasing fouling pressure (more trade in high risk fouling waters, more un-predictable trade with longer idling periods as a result and regulatory demands on limiting risks for transporting aquatic invasive species).

- It leaves room for differentiation as various types of formulation combinations are available.

- It reduces foot print to the marine environment as it reduces the biocidal loadings considerably.

And what are the advantages to the shipowner?

- It can improve the static performance making coatings more flexible and better adapted to the operational pre-requisites and consequently saves a great deal of fuel and reduced need for scrubbing.

- It allows for overall high performing coating systems with sharply reduced levels of active ingredients

- It contributes to reduce the risk of transporting aquatic species which is under great pressure among leading countries and IMO.

When we have this interview again in five years, what do you believe your company will look like?

I am fully convinced that Selektope in five years is part of a number of very well appreciated antifouling products frequently used by also the most demanding owners. As a company, I hope we have been able to manage a large industrial ramp up with our partners yet remaining very close to our customers and to the industries various stake holders. For the bottom line, I do hope we achieve a strong financial position enabling a well-deserved return on investment to all those who have supported us financially.

Read Keeping Hulls Clean One Barnacle at a Time in Pdf, Flash or Html5 edition of August 2016 Maritime Reporter

Other stories from August 2016 issue

Content

- Artificial Stupidity page: 14

- The Economics of Ship Breaking & Scrapping page: 18

- The Past, Present & Future of the ‘Noon Report’ page: 22

- The European Network of National Maritime Clusters page: 24

- Growing Up Metric page: 32

- Keeping Hulls Clean One Barnacle at a Time page: 46

- Astican & Astander Continue to Invest page: 60

- German Shipbuilders Strong in a Weak World Market page: 64

- DPS & Closing the Door on Unnecessary Risk page: 74

- Lifetime Assessment for Deepwater Moorings page: 78

- Green Ships & Compliance page: 80

- Better Turbocharger Performance, Proven Tech page: 94

- Five Minutes with Paul Switzer page: 106