Type

-

- Tankers, Bulkers & the Increased Need for Software Solutions Maritime Reporter, Dec 2015 #18

Tankers

IMO/adopted guidelines for the mandatory carriage of damage stability verification instruments (software, computers, etc.) onboard all (new and existing) tankers beginning in January 2016.

IMO

IMO has adopted guidelines and applicable IMO Code amendments for the mandatory carriage of damage stability verification instruments onboard new and existing tankers. Amendments to MARPOL Annex I, BCH Code, IBC Code, IGC Code and to the Survey Guidelines under HSSC to mandate the provision of a computer program capable of calculating the applicable damage stability requirements were agreed. The approval generally applies to the software, but may include hardware, for example, when the instrument receives input from sensors for the contents of tanks.

New tankers will need to comply on delivery and existing tankers will need to comply at the first scheduled renewal survey after January 1, 2016 (July 1, 2016 for Gas Carriers) but no later than January 1, 2021.

The Issue

All tank vessels on international voyages must meet the International Maritime Organization’s (IMO) requirements for damage stability. These regulations are contained in the MARPOL Convention for general purpose tankers, the IBC and BCH Codes for bulk chemical carriers, and the GC and IGC for gas carriers.

In 2005 several Port States, led primarily by the UK’s Maritime and Coast Guard Agency (MCA), recognized that many tank vessels had onboard documentation to demonstrate compliance with these damage stability requirements only when the ships were loaded in accordance with the ships standard loading conditions in the approved Stability Booklet or Loading Manual. However, during actual operations many tank ships are loaded to conditions which significantly differ from these standard loading conditions. A survey by the MCA indicated that “more than 50 percent of vessels are operating in conditions which are not in the approved Stability Information Booklet.”

In 2010 the Paris Memorandum on Port State Control carried out a Concentrated Inspection Campaign to verify correct damage stability on oil tankers, chemical tankers and gas carriers. The reasons for this Concentrated Inspection Campaign included that inspections showed tankers frequently sailing when not complying with damage stability requirements or had no means of assessing damage stability or were sailing in a loading condition not covered by the approved Stability Booklet or Loading Manual. The Concentrated Inspection Campaign Report stated; that a significant number of tankers during a “spot check” could not show compliance with stability requirements and thus may pose a risk to the environment. It is generally understood that since most tank vessels use computer programs to evaluate stability and strength for any loading condition, there no longer is a practical incentive to stay with the standard loading conditions.

Special Dispensation

The Flag Administration may give special dispensation from the provisions of a stability instrument in the following instances:

• tankers where stability is remotely verified by a means approved by the Administration;

• tankers on a dedicated service, with a limited number of permutations of loading such that all anticipated conditions have been approved;

• tankers which are loaded within an approved range of loading conditions; and

• existing tankers provided with approved limiting KG/GM curves covering all applicable intact and damage stability requirements.

The Administration should take into account the Guidelines for the approval of stability instruments(MSC.1/Circ.1229) when reviewing them.

Stability software should be approved, but hardware approval is not mandatory and can be covered by national standards.

Commentary on Compliance

Limiting the number of loading permutations or range of loading is not a practical operational restriction for many, if not most, tank ships. Practical reliance on gaining voyage specific approvals on a timely basis may also be a burden to both the operator as well as the national administration, and may limit operational flexibility.

Many ships are currently operating effectively and safely, using approved limiting KG/GM curves, covering all applicable intact and damage stability requirements. For this type of system the limiting KG (or required GM) curves vs. draft are pre-developed and pre-approved, and would typically be added to both the Stability Booklet and the loading computer. This would normally insure compliance with both the damage stability and intact stability requirements. However, in practice, these curves are complicated and expensive to produce, and also have other application and enforcement concerns as noted in MSC 82/18/3, “because of the need to consider all possible loading and damage combinations and any associated limiting provisions such as tank filling ratios. The resulting stability books may be complex and not easily applied by ships’ officers and Port State control inspectors”. For these reasons Herbert-ABS Software Solutions LLC (Herbert-ABS), generally does not recommend this approach.

The best practical solution is to fit onboard damage stability verification instruments on all tank vessels as required. A direct damage stability loading instrument provides a solution that will make it easy to demonstrate compliance with the damage stability requirements to the Port State authorities for any cargo or ballast distribution.

The Solution

The use of an approved computer program, to verify that the non-standard loading condition complies with the damage stability requirements, can be readily applied to new ship loading computers or implemented as an upgrade to existing loading computer programs.

Loading computer programs with this feature are generally referred to as “IACS Type 3 Loading Instruments” as specified in IACS URL 5 (applicable for new buildings since July 2005), which define Type 3 as “software calculating intact stability and damage stability by direct application of preprogrammed damage cases for each loading condition.”

Herbert-ABS’ CargoMaxTM loading computer with the Direct Damage Stability (DDS) module fully meets the requirements of IACS URL 5, Type 3, for any type of tank vessel. It demonstrates compliance with the damage stability requirements for any of the relevant regulations from IMO and national administration for any type of loading or ballast loading. It can also be used to demonstrate this compliance to Port State inspectors or vetting surveyors.

Pre-existing Onboard Software

Loading computer software previously approved for stability can be classified as one of three types as defined by IACS UR L5:

• Type 1 software calculates intact stability only through the use of an intact required Max GM/ KG curve.

• Type 2 software calculates intact stability and checks damage stability using a combined intact and damage stability required GM/Max KG curve.

• Type 3 software calculates intact stability and damage stability by direct application of preprogrammed damage cases for each loading condition (DDS). Determining which software type an existing CargoMaxTM falls under may not be clear through the existing approval documentation.

It is not always straight forward to determine the URL5 type. The first place to check is the software’s class approval letter. If the approval letter states that the approval is for ‘intact strength only’ then the software was not previously approved for stability and is not classified as a URL5 type software. While the loading program likely has either an intact only or intact/damage required GM curve, the stability portion of the program was not reviewed or approved by the classification society. If the approval letter mentions stability approval, then the software can be classified as one of the three types.

Most recent approvals mention the software type in the approval letter. However for software delivered prior to 2004 as well as for some more recent deliveries, the approval letters do not mention the type. If this is the case, the software type can be determined by review of the loading program and the vessel’s Trim and Stability booklet or Loading Manual. In the loading program documentation, an inspection of the Required GM curves and calculation options could reveal the type. If the option to ‘Calculate Direct Damage Required GMr’ is available, then this software has Direct Damage Stability calculations enabled (DDS) and is considered Type 3. If not, then the software likely utilizes either an intact only or intact/damage required GM (or max KG) curve. The name of the curve can sometimes be taken from the program by looking at the Trim and Stability summary. If the curve is labeled ‘Damage’ then this program is a Type 2. The type of Required GM curve used can usually be found in the ship’s Trim and Stability Booklet. If the Required GM curve is derived based on intact stability criteria only, the software is Type 1, but if the Required GM curve incorporates both intact and damaged stability, then the software is Type 2.

Bulkers

Damage Stability Requirements for Bulk Carriers

Introduction:

The great majority of bulk carriers are designed to the reduced B-60 freeboard, Type B freeboard, minus 60 percent of the distance to the Type A freeboard. With this reduced freeboard, the ICLL66 convention, Reg, 27, requires compliance with a fairly conservative damage stability standard only at the summer loadline draft. These regulations specify a 1-compartment damage, with the holds loaded at their 100 percent homogeneous load VCG, and a permeability of 0.90. This is usually considered by a ‘design only’ requirement and once the damage analysis for all 1-compartment damage is met for this design case, operationally, the ship is not required to meet any damage stability requirements.

There are two other interesting cases where other damage stability regulations apply:

Bulk Carriers with Type B Freeboards

Type B ships constructed before February 1992 were not required to meet any damage stability standards. However, all Type B ships constructed after February 1992 are required to meet the SOLAS Ch. II-1, Part B-1 probabilistic regulations, unless they are covered by other regulations (such as Reg. 27 of the ICLL).

New retroactive requirements for bulk carriers came into force as part of SOLAS Ch. XXI. Regulation 4 of this chapter covers the new damage stability requirements, which must be met for bulk carriers constructed after July 1999, flooding each individual cargo hold. This can be considered the damage stability equivalent of the S17 hold flooding structural requirements.

It should be noted that ships meeting ICLL Reg. 27, the B-60 freeboard ships, are exempt from the new Reg. 4 requirements, so this essentially only applies to the minority of bulk carriers with only Type B freeboards.

The Reg. 4 requirements were originally considered to be a ‘design only’ requirement, in order to fulfill the obligation of producing a design study to demonstrate compliance with Reg. 4, which included damage of each individual cargo hold (at a permeability at 0.90), at the loadline draft, at a GM of 0.40m, and a range of trims. This was not recommended by class and they commented as follows:

“Separate design calculations in accordance with SOLAS Reg. XII/4 are not recommended as it may introduce trim limits not defined by the designer/shipyard. Please note that the underlying principle is that the loading computer software shall reflect the required onboard documentation.

In compliance with classification society recommendations, the “Bulk Carrier DDS” was put to use, which includes a direct damage stability simple run through damage cases for each bulk cargo hold to verify compliance with Reg. 4 damage stability, thereby meeting the ICLL Reg. 27 stability standard. This procedure has been implemented in CargoMaxTM and when required done simultaneously with the S17 hold flooded strength calculations.

Bulk Carriers with Type B-60 Freeboards and Deckloads

Since bulk carriers with deckloads can have a VCG even higher than the conservative 100 percent full homogeneous CG required by ICLL Reg. 27, these damage requirements are considered to be inadequate and need to be supplemented by the SOLAS B-1 probabilistic requirements, see IACS LL65.

The B-1 probabilistic requirements are generally considered less conservative than the Reg. 27 deterministic requirements. Nonetheless, attention needs to be paid to provision 4 of IACS LL65, which states:

“The KG used for demonstrating compliance with the criteria in 3a (the ICLL Reg. 27 calculations) shall be the same as that used for the criteria in 3b (probabilistic B-1 calculations) at the subdivision loadline.”

This means that even if the B-1 calculations with a higher VCG (lower Req. GM) are met, the relatively conservative VCG (high GM) from the Reg. 27 calculations at the deep waterline must still be used. In essence this stipulates that since ships cannot have cargo with a VCG higher than the homogeneous cargo hold, they are prevented from having any significant deckload at the deep waterline. Depending on the Partial Draft Req. GM to meet the B-1 damage requirements, ships can get progressively more deckload at lighter and lighter drafts.

Class has conceded that the Reg. 27 calculations might be easily met for some ships, and the ship in question could meet the ICLL damage stability criteria with a cargo VCG even higher than the homogeneous fully loaded holds. In this case class states:

“Redoing the ICLL Reg. 27 calculation with a lower GM (higher VCG) than required by the standard initial condition in order to use this lower GM for the subdivision draft GM in the probabilistic calculations is an acceptable solution.”

The Author

Hendrik Bruhns, Naval Architect, President of Herbert-ABS Software Solutions LLC. Previously he headed the Stability Department of Germanischer Lloyd and has participated in and chaired numerous Committees at IMO.

e: [email protected](As published in the December 2015 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)

-

- The Strong and Silent Type Marine News, Jul 2017 #34

Mapping and shaping the growth of marine hybrid means many things to different stakeholders. The journey leads us all to the same place. If you follow the advancements in automotive design, the term or tag “hybrid” has come to define the alternative energy movement on our roads and highways. HEV autos

-

- Energy Storage - Now Relevant for Any Vessel Type Marine News, Nov 2018 #76

vessels have crossed the oceans using some kind of energy safely stored on board. Be it Coal, Diesel, Gasoline or Natural Gas, and regardless of energy type, safe storage onboard has been vital for safety and completion of the planned trip. On the other hand, active use of batteries in propulsion systems

-

- Great Ships 2018: World’s Largest MOSS Type LNG Carrier Maritime Reporter, Dec 2018 #31

Pacific Breeze, a 182,000 cu. m. capacity LNG carrier, is the world’s largest MOSS type LNG carrier ever constructed, built at Kawasaki Heavy Industries, Ltd., Japan (KHI). This capacity was achieved by extending the equatorial ring section of No. 3 and 4 cargo tanks by 1.6m in height from the conventio

-

- Hyde Marine’s IMO Type Approved Hyde GUARDIAN Gold BWT Marine News, Mar 2014 #55

Hyde’s GUARDIAN Gold Ballast Water Treatment System offers the smallest footprint for easy installation and combines auto-backflushing filtration with reliable UV disinfection technology in a chemical free process. UV treatment is unaffected by salinity or temperature, without producing hazardous byproducts

-

- Trojan Marinex BWT System Earns IMO Type Approval Maritime Reporter, Apr 2014 #106

Trojan Technologies announced that the Trojan Marinex Ballast Water Treatment (BWT) product suite has obtained IMO Type Approval from DNV on behalf of the Norwegian Maritime Directorate. “We are the largest UV company in the world, and are committed to providing pioneering water treatment technologies that

-

- Victaulic Vic-Press System Receives Five New Type Approvals Maritime Reporter, Aug 2014 #119

Victaulic received type approvals from American Bureau of Shipping (ABS), Bureau Veritas (BV), Det Norske Veritas (DNV), Korean Register and Lloyd’s Register for Vic-Press, a flame-free press system for joining small-diameter stainless steel pipe. Shipbuilders can take advantage of Vic-Press as a quick

-

- Nera F 5 5 Terminal Gets Inmarsat Type Approval Maritime Reporter, Sep 2003 #44

Inmarsat granted full type approval to the new Nera F55 maritime communication terminal. Tailored for small to medium-sized vessels, the product completes Nera's family of Inmarsat Fleet communication solutions. "The terminal is authorized for use and is available in all markets where Inmarsat

-

- Versatile Pacific Delivers Canadian Coast Guard Type '500' Search And Rescue Cutters Maritime Reporter, Nov 1991 #121

Versatile Pacific Shipyards Inc., Victoria division, recently delivered two new Type "500" SAR cutters to the Canadian Coast Guard. The vessels—CCGS Gordon Reid and John Jacobson—bear the names of two noted British Columbia native Indians, both of whom had strong ties to the maritime community.

-

- Red Fox Announces New Type Marine Sanitation Device Maritime Reporter, Mar 1978 #29

The Red Fox Type II Marine S a n i t a t i o n Device features a unique, pressurized clarifier chamber which keeps liquid in a motionless state. Sludge settling rate is not affected by vessel pitch or roll. Efficient flow-through system eliminates periodic sludge dumping. Effluent discharge consistent

-

- NSF Certifies Demco Aeration Type Packaged Sewage Treatment Maritime Reporter, Apr 15, 1977 #52

A line of extended aeration type packaged sewage treatment plants manufactured by Demco Incorporated has been certified by the National Sanitation Foundation (NSF) for onshore and offshore use. Demco offers the plants in 18 sizes ranging in capacity from 325 to 12,500 gallons of sewage daily (from

-

- M/S Yulius Fuchik, First Of Two Valmet-Built Lykes SEABEE-Type Barge Carriers For USSR Maritime Reporter, Dec 1978 #7

The first Lykes SEABEE-type barge carrier for the Soviet Union, the M/S Yulius Fuchik, was delivered in Helsinki on October 20 by the builder Valmet Oy of Finland. Yalmet had previously contacted Lykes Bros. Steamship Company in Europe and received license rights to build two SEABEE- type vessels

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42for battery packs and thrusters for crewed and uncrewed subsea vehicles that re- quire high amperage power transfer. Select sizes are already being DNV type-approved for 6km rated crewed submers- ibles. BIRNS Meridians are compact, and feature several pin con? gurations, with more in design for release

-

)

March 2024 - Marine Technology Reporter page: 38

)

March 2024 - Marine Technology Reporter page: 38en- from West Mountain Radio (https://www.westmountainra- ergy densities, self-discharge rate of up to 30%/month, and dio.com/). The CBA V can test any type or size of battery, any display some memory effects. Their max discharge rate is 5C. chemistry or number of cells, up to 57 volts, and up to 200

-

)

March 2024 - Marine Technology Reporter page: 37

)

March 2024 - Marine Technology Reporter page: 37Mountain Radio CBA V, can be done to replicate this experiment yourself. (See Figure 7.) ? Gel cell Sealed Lead-Acid (SLA) batteries substitute a gel-type electrolyte for the liquid in basically a wet-cell lead acid battery. This permits it to be used in any position. They Photo Science, Vol 162, #3849

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30sediment disturbance, it has a Greg Stone, Chief Ocean Scientist. ? nes rejection system. Research conducted by Nauru Ocean Resources, a subsid- This type of technology was ? rst tested successfully in the iary of The Metals Company, found that organisms continue 1970s by major Western corporations

-

)

March 2024 - Marine Technology Reporter page: 23

)

March 2024 - Marine Technology Reporter page: 23vent and mineral deposits form.” IN THE What’s All the Comm-ocean? The HT-HH eruption added to the unknowns about submarine vol- AFTERMATH canoes. This type, a stratovolcano, is very common and not believed to generate an eruption of such magnitude. “Why was the eruption blast so powerful,” asked Mackay

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design, modelling, structure is the large amount of accurate information obtained project management, inspection, over a

-

)

March 2024 - Marine Technology Reporter page: 13

)

March 2024 - Marine Technology Reporter page: 13use of Slocum Gliders grew, Manager at TWR. A familiar with the popular- so did demand for increased capabil- The Slocum Sentinel Glider scales ity this type of platform has seen over ity: longer missions, more sensors – the standard Slocum Glider through an the past two decades, growing from especially

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11. But this will be neither quick nor easy given the volume of mine-like ob- jects scattered across the bottom of the Black Sea, and an unknown number and type of sea mines laid (and yet to be laid) by both Ukrainian and Russian forces. Modern MCM technologies and related CONOPS will ? nally come into their

-

)

April 2024 - Maritime Reporter and Engineering News page: 43

)

April 2024 - Maritime Reporter and Engineering News page: 43part of the shipping, and to the vetting of the sys- ery objective, given the diversity of ship IMO’s review of its formulation of the tems in service.” types, ship ages, routes and services.” CII, or as EU standards evolve to sup- What is also already known is that all port FuelEU maritime requirements

-

)

April 2024 - Maritime Reporter and Engineering News page: 25

)

April 2024 - Maritime Reporter and Engineering News page: 25. Correct. MSC has responsibilities and authorities that who know steam plants. I can say that we’re expending a lot span the entire Navy. I’m a “type commander,” responsible of resources to allow our older ships to continue to perform. for the “man, train and equip” function that generates forc- es

-

)

April 2024 - Maritime Reporter and Engineering News page: 14

)

April 2024 - Maritime Reporter and Engineering News page: 14, marine engineers, and ship Statistical Energy Analysis (SEA) or Finite Element Analysis builders. This speci? cation must be appropriate for the type (FEA). The most accurate are those that can account for all and function of the vessel. The limits should be achievable the machinery transmitting

-

)

April 2024 - Maritime Reporter and Engineering News page: 10

)

April 2024 - Maritime Reporter and Engineering News page: 10Phased Roll-out Core questions are mandatory for every inspection, irre- The roll-out of SIRE 2.0, which entered its third phase in spective of the vessel type, operations, or any speci? c voyage January with trial inspections available to all program users, details. These questions cover essential aspects

-

)

April 2024 - Marine News page: 43

)

April 2024 - Marine News page: 43at ABB Marine & new safety features are unlocked: Risk Ports based in Finland. 2. In-Mar Solutions: Visualizer and AI Avoidance Route. Wynn Marine Type C NavNet TZtouchXL also supports & Type D, HeavyDuty 5. TRACE-M250 tools like AIS and autopilot, along with EH Group said its EH Fuel Cell

-

)

April 2024 - Marine News page: 39

)

April 2024 - Marine News page: 39ef? ciency gains and reduce challenges posed by each shipyard and process. This stage poses critical ques- the need for rework, showcasing the vessel type. Contrary to popular expe- tions: Should the steel be processed in- importance of thoughtful process- rience and opinion, modern solutions house with

-

)

April 2024 - Marine News page: 38

)

April 2024 - Marine News page: 38? tting areas underscores the necessity of a bespoke approach for maximizing ef? ciency in their respective blast and paint processes. Navigating ship types and their unique challenges The complexity within shipyards is magni? ed by the variety of vessels under construction, whether tankers or surface

-

)

April 2024 - Marine News page: 33

)

April 2024 - Marine News page: 33ABB, a 6.2 MWh Orca battery energy storage system from Corvus Energy, two 2,100 kW RAMME motors, and two electrically driven Schottel Rud- derPropellers type SRP 430 LE azimuthing thrusters, fea- turing propeller diameters of 2.5 meters. The vessel also has From left: Chairman Frank Urtasun, Board of two

-

)

April 2024 - Marine News page: 27

)

April 2024 - Marine News page: 27Shipbuilding Group is building Two 2024 announcements from Eastern Shipbuilding the ? rst four Offshore Patrol Cutters provide a window into the types of commercial projects for the U.S. Coast Guard. that sophisticated yards can take on. It announced a deal with a ? nancial owner (which acquired

-

)

April 2024 - Marine News page: 22

)

April 2024 - Marine News page: 22(OREI) on the Outer Continental Shelf (OCS).” This 69- areas” – would con? rm a central mission: maintaining and page document details degrees and types of risk for different securing safe navigable waters for vessels transiting waters vessels and vessel combinations. Towing at sea, for example,

-

)

February 2024 - Maritime Reporter and Engineering News page: 43

)

February 2024 - Maritime Reporter and Engineering News page: 43six recommendations that may affect this. Currently, reports on also affects the Coast Guard’s ability to the Coast Guard, among other things, these types of issues are expected to be retain personnel. For example, in April obtain, share, and monitor several released in 2024 and 2025. 2023 GAO found

-

)

February 2024 - Maritime Reporter and Engineering News page: 42

)

February 2024 - Maritime Reporter and Engineering News page: 42of February 2022, the Coast Guard cast workforce needs for certain ves- and retain the personnel necessary to had not used its workforce determina- sel types (cruise ships) but not others conduct its diverse array of mission re- tion process to assess 55 percent of its (freight vessels). The Coast Guard

-

)

February 2024 - Maritime Reporter and Engineering News page: 40

)

February 2024 - Maritime Reporter and Engineering News page: 40hit the water. Ultimately, like any other business, cost is a top-agenda “We want to make sure that we develop a design that's go- driver. Regardless of type, fuel prices will ? uctuate by supply ing to work and that's going to be safe,” said Brindley. “The and demand as well as geopolitical factors. But

-

![MR Feb-24#39 volumes. It’s about segrega-

X type] on ammonia at its Research](https://images.marinelink.com/images/magazines/w200h250c/MaritimeReporter-202402-page41.png) )

February 2024 - Maritime Reporter and Engineering News page: 39

)

February 2024 - Maritime Reporter and Engineering News page: 39, how you pull your pipes between ? rst running of a test engine [MAN B&W two-stroke 4T50ME- compartments and the larger tank volumes. It’s about segrega- X type] on ammonia at its Research Center Copenhagen (RCC). tion because of the toxicity.” While the accomplishment is real, challenges remain, as Safety

-

)

February 2024 - Maritime Reporter and Engineering News page: 15

)

February 2024 - Maritime Reporter and Engineering News page: 15idle or loiter times outside of port that would otherwise be lost time for the ship. The economic viability of hull cleaning differs from most other types of ship maintenance, as there is a direct return on the cost of the cleaning recognized through fuel savings. Bio? lms and microfouling increase

-

)

February 2024 - Marine News page: 38

)

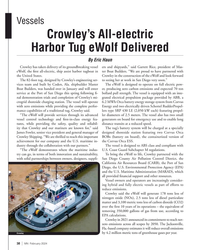

February 2024 - Marine News page: 38while providing the complete perfor- Energy and two electrically driven Schottel RudderPropel- mance capabilities of a traditional tug, Crowley said. lers type SRP 430 LE (2,050 kW each) featuring propel- “The eWolf will provide services through its advanced ler diameters of 2.5 meters. The vessel also has