Arctic Technology

-

- Beyond the Tip of the Iceberg Tech: RDT&E's Annual Arctic Technology Evaluation Marine Technology, Sep 2020 #18

The Coast Guard Research and Development Center (RDC) teamed up with Coast Guard Cutter Campbell’s crew this summer to evaluate five technologies as part of the RDC’s annual Arctic Technology Evaluation. The Campbell crew conducted the evaluations during their two-month deployment supporting joint Arctic operations off Greenland’s western coast, returning to their Kittery, Maine, homeport on Sept. 29, 2020.

“Testing various technologies by cutter crews for operation in cold and Arctic environments provides highlights on what works and what may need improvement, and can help influence tactics, techniques and procedures,” said Brian Dolph, who heads the RDC’s Surface Branch. “This work directly contributes to two lines of effort in the Coast Guard Arctic Strategic Outlook: ‘Enhance Capability to Operate Effectively in a Dynamic Arctic’ and ‘Innovate and Adapt to Promote Resilience and Prosperity.’ ”

The RDC adjusted its testing approach because of the COVID-19 pandemic; typically, at least one RDC staff member would be onboard the cutter as the lead scientist during testing. The year the RDC relied on detailed user manuals and technical reports produced for training and remote connectivity with the Campbell during testing. Matthew Lees served as the RDC demonstration director while Lt. Mathew Lara, Campbell operations officer, assigned duties aboard the ship.

The technologies selected for evaluation:

- Insight Mini Thermal Monocular (MTM) and AN/PSQ-20 Monoculars (enhanced night vision devices) for improved law enforcement and ice detection.

- Handheld Glare Helios laser for stand-off hailing capabilities.

- FiFish Remotely Operated Vehicle for underwater inspections in cold weather.

- Long Range Acoustic Device 500X-RE for enhanced communication with vessels at longer distances.

- Iridium Certus Terminal, which helped provide internet access for the crew to maintain communications with Atlantic Area.

Amber Boguslawski utilizes the AN/PSQ-20 Monoculars (enhanced night vision devices) during a look-out watch on the bridge of the U.S. Coast Guard Cutter Campbell. U.S. Coast Guard photo by SN Kate Kilroy

Amber Boguslawski utilizes the AN/PSQ-20 Monoculars (enhanced night vision devices) during a look-out watch on the bridge of the U.S. Coast Guard Cutter Campbell. U.S. Coast Guard photo by SN Kate Kilroy- Monoculars

The AN/PSQ-20 fused monoculars were evaluated on their ability to determine ice edge and targets of interest during normal watch operations; the technology was successful, especially at night. This technology allowed crew members to sight an iceberg quickly and give accurate data on size and shape.

The MTM was integrated via adapter cable to broadcast to the Campbell’s displays to support law enforcement and flight operations. “These tools functioned well to identify land, shipping and icebergs at night, providing detailed images of objects. Highly recommend future use,” said Capt. Thomas Crane, Campbell commanding officer.

- Handheld Glare Helios

The Glare Helios laser was tested in both day and night operations using a manned over the horizon (OTH) boat. During daylight hours, crewmembers onboard the OTH small boat detected the laser up to 8,000 yards from Campbell. During night hours, the laser was even more effective and could been seen over the horizon (approximately nine nautical miles). The Arctic environment did not hinder the operational ability of the Glare Helios.

The OTH crew reported it was immediately apparent the laser was pointed at them and believed the laser would be a valuable part of a boarding kit, especially when pursuing non-compliant vessels.

- FiFish Remotely Operated Vehicle (ROV)

The Coast Guard recently authorized the use of low-cost ROVs to enhance the effectiveness of the fleet; this demonstration proved this technology is also viable in polar environments. The demonstration highlighted maintenance efficiencies by reducing the number of crew-hours and risk to personnel required to perform time-consuming dives and providing on-demand inspection of hulls and piers.

ENS Liam Middleton, LT Stephen Hills and ET1 Douglas Locklear run the FiFish Remotely Operated Vehicle (ROV) to inspect under the waterline of the CGC Campbell. U.S. Coast Guard photo by SN Kate Kilroy

ENS Liam Middleton, LT Stephen Hills and ET1 Douglas Locklear run the FiFish Remotely Operated Vehicle (ROV) to inspect under the waterline of the CGC Campbell. U.S. Coast Guard photo by SN Kate Kilroy- Long Range Acoustic Device (LRAD) 500X-RE

Underscoring the challenges faced during Arctic operations, weather conditions were generally not favorable for small boat operations, but the LRAD provided clear hailing and communication to small boats up to 500 yards away.

- Iridium Certus Terminal

One of the biggest challenges for polar operations is effective communication. The Iridium Certus Terminal was used in this evaluation to provide a communication method every day, allowing for the easy transmission of multimedia messages and even the establishment of phone communications within the contiguous United States for the crew. “We tested this frequently throughout the patrol to analyze and document the operational suitability. Integrated into the shipboard telephone system, it provided clear communications for command and crew to make operational and emergency calls. It also proved to be highly effective as a back-up internet option when our high latitude operations challenged other technology,” Crane said.

Final results from these five technology evaluations are due at the end of the year.

Campbell also deployed 13 scientific research buoys ranging from the eastern shore of Nova Scotia to the Davis Strait. Daily images of icebergs were provided to the International Ice Patrol to validate and improve satellite reconnaissance. This effort allowed for real-time tracking and iceberg avoidance. “Varied scales of the operation area were readily available and provided over weekends, holidays and after work hours. This well-received, detailed, exceptional support greatly assisted in our operational planning and was critical to mission success,” Crane said.

Campbell’s crew also contributed to joint search and rescue exercises with the French and Royal Danish navies, facilitated key diplomatic engagements, and supported National Oceanic Atmospheric Administration and International Ice Patrol iceberg research during the 11,500-mile deployment. Campbell became the first 270-foot medium endurance cutter to earn the Arctic Service Medal.“This effort strengthens international partnerships and provides a foundation for standard operations in the rapidly developing Arctic maritime environment,” said Vice Adm. Steven Poulin, commander U.S. Coast Guard Atlantic Area. “As interest and maritime traffic in the area increase, the importance of the U.S. Coast Guard’s interoperability with allied partners becomes more critical to ensuring we protect national and shared security interests. Exercising our unique blend of polar operational capability, regulatory authority, and international leadership across the full spectrum of maritime governance is vital to the future of the Arctic.”

About the Author: Ms. Karin Messenger is the Environment and Waterways and Arctic Domain Lead for the Coast Guard Headquarters Office of Research, Development, Test & Evaluation and Innovation.

ENS Jordan Solseth runs a test for the Long Range Acoustic Device (LRAD) 500. U.S. Coast Guard photo by SN Kate Kilroy

ENS Jordan Solseth runs a test for the Long Range Acoustic Device (LRAD) 500. U.S. Coast Guard photo by SN Kate Kilroy -

- S e m i n a r M a r k s O p e n i ng O f W a r t s i l a O f f i c e In V a n c o u v e r , B.C., C a n a da Maritime Reporter, Apr 15, 1984 #36

To mark the opening of a branch office in Vancouver, British Columbia, Wartsila, Finland's leading company in Arctic technology, held a one-day seminar of scientists and experts from Canada and the United States at the Hyatt Regency Hotel in Vancouver. Wartsila Arctic Inc. (WAI) invited some 80

-

- Finnish Shipbuilding and Arctic Operations Maritime Reporter, Jun 2013 #54

of ship, both regarding icebreaking as well as oil spill combating technology. The design of the vessel is based on the ARC100 concept which Aker Arctic Technology has developed for Arctech Helsinki Shipyard. It features a patented oblique design with asymmetric hull and three azimuthing propulsors, which

-

- KMY To Consult on Icebreaker Maritime Reporter, Mar 2002 #8

Kvaerner Masa Marine (KMM) and Masa-Yards Arctic Technology Center (MARC), both part of the Kvaerner Masa-Yards Group, were recently awarded a contract to provide ice breaking consulting services and model testing for the USCG Great Lakes Icebreaker currently being designed by Marinette Marine Corporatio

-

- KMY Helps Breaks the Ice in Russia Maritime Reporter, Nov 2003 #97

be fitted with two azimuthing rudder propellers. These ships are based on the "double-acting" concept for icebreakers, which was developed by the Arctic Technology Center (MARC), part of Kvaerner Masa-Yards Inc. In this concept the vessel meets the most difficult ice conditions moving with the ship's

-

- Finland: A Hot-Bed of ICEBREAKER Technology Maritime Reporter, Aug 2018 #62

certainly hope that these legal changes will not go through, because we would not be able to operate in the Russian Arctic then.”Put to the TestAker Arctic Technology Inc. runs an ice model basin in Helsinki, Finland. The government-owned Finnish Industry Investment acquired the majority of the shareholding

-

- Wartsila To Provide Power On Unique Icebreaking Tankers Maritime Reporter, Nov 2000 #90

ice each year. They are thus being built to Ice Super class and will follow a revolutionary Double Acting Tanker (DAT) concept developed by the Arctic Technology Center of Kvaerner Masa-Yards in Helsinki. In the DAT concept, the ship is designed for running astern as an icebreaker, and ahead in open

-

- Passage to the High North – When Spray Matters Maritime Reporter, Aug 2015 #18

sea. There is unfortunately scarce validation material available, although what we have matches satisfactorily. Results were published at the Arctic Technology Conference in Copenhagen in March 2014, thereby inviting the industry and other interested parties to provide further validation material. The

-

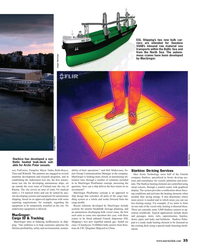

- Maritime Tech Trends Digital Maritime Reporter, Jul 2018 #32

natural gas- fueled ice class 1A handysize 25,600dwt bulk carriers from Sinotrans & CSC Qingshan Shipyard in China. Starkice: De-icing ServicesAker Arctic Technology owns half of the Finnish company Starkice, specialized in Arctic de-icing systems and consultancy for vessels, platforms and terminals. The Starkice

-

- Arctic Research Explores the ‘Roomba’ Approach Marine News, Oct 2017 #36

solicited companies,” Bennett explained, “with the request to get an operational skimming system with thrusters to Alaska by mid-July for the 2017 Arctic Technology Evaluations, but no entity was able to fulfill the deadline request.” Subsequently, Coast Guard personal contacted the Aqua-Guard team in

-

- 'Roomba' in the Arctic Marine Technology, Oct 2017 #40

solicited companies,” Bennett explained, “with the request to get an operational skimming system with thrusters to Alaska by mid-July for the 2017 Arctic Technology Evaluations, but no entity was able to fulfill the deadline request.” Subsequently, Coast Guard personal contacted the Aqua-Guard team in

-

- Canadian Shipbuilding And Offshore And Arctic Prospects Maritime Reporter, Jun 1983 #56

skilled workforce, special metals and components, and a very high level of quality control. So far the advanced ships at the leading edge of Arctic technology have been built in Canada. We believe we have an important lead in this area and we are looking to maintain it. The big threat at the moment

-

)

November 2023 - Maritime Reporter and Engineering News page: 46

)

November 2023 - Maritime Reporter and Engineering News page: 46Technology, an engineering company specializing in icebreakers. “We hold the position as the world leader in this segment.” From left: Aker Arctic Technology managing director, Reko-Antti Suojanen, with director of sales and marketing, Arto Uuskallio. FUTURE DEMANDS AND OPPORTUNITIES gen, and Aker

-

)

November 2023 - Maritime Reporter and Engineering News page: 45

)

November 2023 - Maritime Reporter and Engineering News page: 45world’s “Developing, designing and building icebreaking vessels is very strong in Finland,” said Reko-Antti Suojanen, managing director at Aker Arctic Technology, an engineering company icebreakers, and specializing in icebreakers. “We hold the position as the world leader in this segment.” Suojanen

-

)

June 2021 - Maritime Reporter and Engineering News page: 27

)

June 2021 - Maritime Reporter and Engineering News page: 27USCG ARCTIC TECHNOLOGY EVALUATION tive communication. The Iridium Certus commander U.S. Coast Guard Atlantic shared security interests. Exercising our Terminal was used in this evaluation to Area. “As interest and maritime traf? c unique blend of polar operational capa- provide a communication method

-

)

June 2021 - Maritime Reporter and Engineering News page: 26

)

June 2021 - Maritime Reporter and Engineering News page: 26USCG ARCTIC TECHNOLOGY EVALUATION boat operations, but the LRAD provided clear hailing and Handheld Glare Helios communication to small boats up to 500 yards away. The Glare Helios laser was tested in both day and night op- erations using a manned over the horizon (OTH) boat. During Iridium Certus

-

)

June 2021 - Maritime Reporter and Engineering News page: 25

)

June 2021 - Maritime Reporter and Engineering News page: 25USCG ARCTIC TECHNOLOGY EVALUATION U.S. Coast Guard Cutter Campbell deploys their Over the Horizon (OTH) Small Boat during operations with the Royal Danish Navy near the Jacobshavn Glacier in West Greenland on September 06, 2020. as the RDC demonstration director while Lt. Mathew Lara, Campbell operations

-

)

June 2021 - Maritime Reporter and Engineering News page: 24

)

June 2021 - Maritime Reporter and Engineering News page: 24USCG ARCTIC TECHNOLOGY EVALUATION Beyond the Tip of the Iceberg Tech: GMS RDT&E’s Annual Arctic Technology Evaluation U.S. Coast Guard photos by SN Kate Kilroy By Karin Messenger he Coast Guard Research and Development Center Kittery, Maine, homeport on Sept. 29, 2020. (RDC) teamed up with Coast Guard

-

)

November 2020 - Marine Technology Reporter page: 22

)

November 2020 - Marine Technology Reporter page: 22USCG Arctic Technology Evaluation MONOCULARS of the Glare Helios. The AN/PSQ-20 fused monoculars were evaluated on their The OTH crew reported it was immediately apparent the la- ability to determine ice edge and targets of interest during ser was pointed at them and believed the laser would be a

-

)

November 2020 - Marine Technology Reporter page: 20

)

November 2020 - Marine Technology Reporter page: 20USCG Arctic Technology Evaluation he Coast Guard Research and Development ity with the Campbell during testing. Matthew Lees served Center (RDC) teamed up with Coast Guard as the RDC demonstration director while Lt. Mathew Lara, Cutter Campbell’s crew this summer to evaluate Campbell operations of?

-

)

November 2020 - Marine Technology Reporter page: 18

)

November 2020 - Marine Technology Reporter page: 18USCG Arctic Technology Evaluation Beyond the Tip of the Iceberg Tech: RDT&E’s Annual Arctic Technology Evaluation By Karin Messenger U.S. Coast Guard Cutter Campbell underway during their Arctic deployment off Greenland’s western coast. 18 November/December 2020 MTR #9 (18-33).indd 18 11/3/2020

-

)

August 2018 - Maritime Reporter and Engineering News page: 65

)

August 2018 - Maritime Reporter and Engineering News page: 65.” Ac- Put to the Test ing of 16.8%. The main services of the ing Facility in Turku, which arranges the cording to Lainio, Finland is the only Aker Arctic Technology Inc. runs an company include designing ice going training in their ship bridge simulators. nation in the world capable of providing ice model

-

)

August 2018 - Maritime Reporter and Engineering News page: 64

)

August 2018 - Maritime Reporter and Engineering News page: 64ment and design support including hull of renewing its icebreaker ? eet, provid- Rendering of China’s next Polar icebreaker. Picture: Aker Arctic Technology 64 Maritime Reporter & Engineering News • AUGUST 2018 MR #8 (58-65).indd 64 MR #8 (58-65).indd 64 8/6/2018 11:36:42 AM8/6/2018 11:36:42 A

-

)

July 2018 - Maritime Reporter and Engineering News page: 35

)

July 2018 - Maritime Reporter and Engineering News page: 35, Se- Starkice: De-icing Services Tieto and Wärtsilä. The partners are engaged in several nior Group Communications Manager at the company. Aker Arctic Technology owns half of the Finnish maritime development and research programs, and in MacGregor is looking more closely at maximizing uti- company Starkice

-

)

February 2018 - Maritime Reporter and Engineering News page: 80

)

February 2018 - Maritime Reporter and Engineering News page: 80. . . . . . . . . . .46 21 32 50 00 57Herbert-ABS Software Solutions, LLC . .www.herbert-abs.com . . . . . . . . . . . . . . . .(510) 814-9065 41Aker Arctic Technology, Inc. . . . . . . . . .www.akerarctic.fi . . . . . . . . . . . . . . . .+358 10 3236 300 57Incat Crowther . . . . . . . . . . . . . . . . .

-

)

October 2016 - Marine Technology Reporter page: 42

)

October 2016 - Marine Technology Reporter page: 42on this data, we can develop criteria for various ice scenarios. If I’m working on a design, there is nothing better than full-scale data. At the Arctic Technology Conference here in St. John’s in October, I am presenting a paper, “Estimation of Ice Loads Using Mechanics of Ice Failure in Compression”

-

)

January 2016 - Marine Technology Reporter page: 57

)

January 2016 - Marine Technology Reporter page: 57the ? rst delivery scheduled for gy’ award announced during the annual the ? eld of subsea excavation.” the ? rst quarter of 2016. They have been Arctic Technology Conference last year. Porteous will be targeting new op- purchased by three of the largest multi- Fugro was honored for its development portunities

-

)

October 2015 - Maritime Reporter and Engineering News page: 69

)

October 2015 - Maritime Reporter and Engineering News page: 69between Deltamarin and the Johannesburg educational ployees. In April, Brendan Keavney nounced the addition of naval architect Ltd. and Aker Arctic Technology Inc. institution in Surwold are expand- joined SMSLLC as the new Business Zachary Gilfus and mechanical engineer Apart from being ice strengthened

-

)

July 2015 - Maritime Reporter and Engineering News page: 49

)

July 2015 - Maritime Reporter and Engineering News page: 49new ef? cient loading and un- Managing Director Allied eParts Aker Arctic Acquires Canada’s Akac loading con? gurations possible without Aker Arctic Technology Inc has acquired decreasing passenger and cargo capacity, full ownership of Canadian based com- the designer noted. The air conditioning pany

-

)

August 2014 - Marine News page: 3rd Cover

)

August 2014 - Marine News page: 3rd CoverClose: Dec 12 Tug Boat Technology Market: Training & Education Technical: Arctic / Cold Weather Operations Product: Winches, Ropes & Cranes Arctic Technology Conference Feb. 10-12 – Houston, TX PVA/Maritrends Jan. 18-21, Houston, REGIONAL FOCUS: Gulf Coast FEBRUARY Ad Close: Jan 15 MARCH Ad

-

)

April 2014 - Maritime Reporter and Engineering News page: 46

)

April 2014 - Maritime Reporter and Engineering News page: 46the already broken ice edge down.?Aker Arctic?s model basin was used to experiment with multiple designs and OFFSHORE OIL & GAS ANNUAL © Aker Arctic Technology Inc. Aker Arctic is working with Finnish naval architects Mobimar on a trimaran icebreaker, which is actually a single hull ship with two side

-

)

April 2014 - Maritime Reporter and Engineering News page: 2

)

April 2014 - Maritime Reporter and Engineering News page: 2an interesting interview with Rear Admiral Matt Klunder, the U.S. Navy Chief of Naval Research. By Edward Lundquist IN THIS EDITION143844663256Aker Arctic Technology MR #4 (1-9).indd 2MR #4 (1-9).indd 24/8/2014 11:07:17 AM4/8/2014 11:07:17 A

-

)

February 15, 1983 - Maritime Reporter and Engineering News page: 35

)

February 15, 1983 - Maritime Reporter and Engineering News page: 351-41983 The major international conference and exhibition on every aspect of Offshore and Marine Technology. Conference themes include: • Arctic Technology • Underwater Technology and Diving • Ocean Environment • Ocean Engineering and Ship Handling For further details and conference programme

-

)

June 1983 - Maritime Reporter and Engineering News page: 58

)

June 1983 - Maritime Reporter and Engineering News page: 58workforce, special metals and components, and a very high lev- el of quality control. So far the advanced ships at the leading edge of Arctic technology have been built in Canada. We believe we have an important lead in this area and we are looking to main- tain it. The big threat at the

-

)

June 1983 - Maritime Reporter and Engineering News page: 56

)

June 1983 - Maritime Reporter and Engineering News page: 56workforce, special metals and components, and a very high lev- el of quality control. So far the advanced ships at the leading edge of Arctic technology have been built in Canada. We believe we have an important lead in this area and we are looking to main- tain it. The big threat at the

-

)

April 15, 1984 - Maritime Reporter and Engineering News page: 34

)

April 15, 1984 - Maritime Reporter and Engineering News page: 34In Vancouver, B.C., Canada To mark the opening of a branch office in Vancouver, British Co- lumbia, Wartsila, Finland's lead- ing company in Arctic technology, held a one-day seminar of scien- tists and experts from Canada and the United States at the Hyatt Re- gency Hotel in Vancouver. Wart- sila