Corrosion Protection

-

- Texas Instruments Offers Platinum-Clad Anodes For Corrosion Protection —Literature Available Maritime Reporter, Dec 15, 1983 #7

Texas Instruments has developed a platinum-clad niobium material that has been demonstrated to provide excellent protection for steel structures exposed to corrosive conditions such as underwater (both sea and fresh water) or underground environments.

The material works in an impressed current protection system (ICP). It is available in three forms—mesh, wire, and probe— depending on application conditions.

The mesh material has been successfully demonstrated through years of use to protect underwater pier structures. The probe material is designed for protection of vessels containing or transporting water, as well as underwater structures. The wire material has been shown to successfully prevent corrosion of steel reinforcing bars in concrete structures.

Texas Instruments clad platinum anodes offer significant advantages.

The cladding process provides a coating that is uniformly thick, non-porous and has excellent bond integrity.

Experience has shown that the combination of platinum clad on niobium is well suited to impressed current protection applications.

In service, the platinum remains electrochemically active while the substrate forms an adhesive oxide film that is corrosion resistant. The anodes are said to have higher current-carrying capacity and longer life than designs using other anode materials.

Texas Instruments produces platinum-clad anode materials using a solid phase, cold-bonding process. The material is clad at a heavy gauge and subsequently cold rolled to a finished thickness. The composite structure has a uniform, non-porous platinum surface that interfaces directly with the niobium substrate. Because the metals are joined at the atomic level without adhesives, solder or brazing alloy, they are void-free and cannot be separated.

For further information and free literature, Write 20 on Reader Service Card

-

- American Iron And Steel Institute Publishes Text On Corrosion Protection Maritime Reporter, Nov 1981 #99

American Iron and Steel Institute, Washington, D.C., recently published a new text, "Handbook of Corrosion Protection for Steel Pile Structures in Marine Environments." Authored by corrosion engineers and steel pile specialists, the 260-page book provides an indepth study of the problems and remedies

-

- Booklet Available From Kaiser Chemicals On Corrosion Protection Maritime Reporter, Feb 1980 #39

provide improved cathodic protection for offshore oil structures and vessels is the subject of a booklet available from Kaiser Chemicals. It offers corrosion engineers guidance on anode selection and essential factors in the design of a more efficient cathodic protection system, and includes a detailed

-

- ASNE Long Beach-Greater Los Angeles Section Discusses Corrosion Protection And Control Maritime Reporter, Dec 15, 1978 #30

be done in accordance with approved procedures by qualified personnel. The metal spray is generally applied to about 3 to 4 mils thickness for corrosion protection, while the ceramic spray, which is known commercially by the trade name SermeTel, is generally applied about 1 mil thick to nonporous surfaces

-

- Gold Eagle Targets Corrosion Protection Marine News, Jan 2014 #56

360° Protection Ethanol Treatment and Fuel Stabilizer. Designed to combat the corrosive properties of ethanol-blended fuels, STA-BIL 360° delivers corrosion protection above and below the fuel line. STA-BIL 360° releases a vapor inside the fuel system that coats metal parts. Offering 360 corrosion protection

-

- Haraco Services Now Part of Miihlhan Group Maritime Reporter, Oct 2002 #51

Haraco Services Pte Ltd, a Singapore based Corrosion Protection Contractor formed in 1986, has been recently acquired by the Miihlhan Group, a worldwide operating Surface Protection Specialist, based in Germany. Haraco established its name as a reputable contractor, providing Tank Internal Coating

-

- Coating Selection Delivers Fleet Uniformity – Even After Touchups Marine News, Apr 2018 #48

– the hull and the pilot house. Following this construction method, compared to building the vessel as one complete unit, offers advantages for corrosion protection. Vessels built in one piece often have difficult-to-reach areas that applicators may miss or not coat sufficiently, which increase the potential

-

- Marine coatings & corrosion control Maritime Reporter, Aug 1981 #40

any such problems and provide the shipper with a coating that will allow carriage of a wide cargo range. The importance of providing adequate corrosion protection for the often neglected area of ballast tank linings has long been realized at Camrex. As such, several coating types have been developed

-

- Lockheed Expands Houston Office To Provide More Offshore Services Maritime Reporter, Apr 1983 #101

. Services include field engineering support, design engineering support, assembly and repair of oil-spill cleanup equipment, and offshore corrosion protection equipment, the company announced recently. As a result, the facility has moved its Houston office to 1400 North Belt East, Suite 160. The new

-

- Marine coatings & corrosion control Maritime Reporter, May 1985 #36

its Apexior® line of protective coatings to the maritime industry for more than 70 years. Two grades of the Apexior coating offer long-lasting corrosion protection for metal exposed to fresh or salt water over a wide range of temperatures. Apexior Number 1® is a heatresistant coating for metal surfaces imme

-

- Marine coatings & corrosion control Maritime Reporter, May 1984 #26

Apexior" line of protective coatings to the maritime industry for more than 70 years. Two grades of the Apexior coating offer long lasting corrosion protection for metal exposed to fresh or salt water over a wide range of temperatures. Apexior Number 1® is a heat-resistant coating for metal surfaces im

-

- North Sea Corrosion Conference Papers Now Available In Book Form Maritime Reporter, Jan 15, 1980 #36

Performance Coating of the Offshore Industry"; D. Bayliss and F.G. Dunkley, BIE, A n t i - C o r r o s i on Ltd., "Some Aspects of Offshore Corrosion Protection"; G. Bailey, M.Sc., Ph.D., CChem., MRIC, Corrosion and Protection Centre Industrial Services, The University of Manchester Institute of

-

)

March 2024 - Marine Technology Reporter page: 35

)

March 2024 - Marine Technology Reporter page: 35Figure 1 A self-righting vehicle design with buoyancy high and weight low, WHOI’s SeaBED AUV captures the attention of a pair of curious Antarctic penguins as it is deployed from the British research vessel James Clark Ross. Vehicle designers allowed for temperature reduction of battery capacity. Recharge

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19About the Author vey with the pipe tracker is not required, resulting in signi? - Svenn Magen Wigen is a Cathodic Protection and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design

-

)

March 2024 - Marine Technology Reporter page: 18

)

March 2024 - Marine Technology Reporter page: 18as for an cient and thorough assessment of maritime structures’ protec- exposed pipeline. It integrates with active pipe trackers (e.g., tion against corrosion than possible with stab surveys or dual TSS440) as the signals from the tracker do not affect the sen- cell ? eld gradient surveys. sor readings

-

)

March 2024 - Marine Technology Reporter page: 17

)

March 2024 - Marine Technology Reporter page: 17the data these work- estimate due to poor visibility, the presence of marine growth streams demand can have implications across the board, from and/or corrosion products, or due to the anode being buried in reducing the risk of spill events on pipelines to saving time seabed sediments or under rock dump

-

)

March 2024 - Marine Technology Reporter page: 16

)

March 2024 - Marine Technology Reporter page: 16need for frequent repairs and used to safeguard underwater pipelines and struc- replacements, which also aligns well with sustainable opera- tures from corrosion, is relatively straightforward. tional practices in the offshore industry. However, in order to Made of alloys like aluminum, Zinc and is some

-

)

March 2024 - Marine Technology Reporter page: 6

)

March 2024 - Marine Technology Reporter page: 6, a research and strategic advisory focusing on autonomous undersea Lundquist Wigen systems. Wigen Svenn Magen Wigen is a Cathodic Protection and corrosion control expert having worked across engineering, design, modelling, project management, inspection, sales, marketing and management in the sector

-

)

April 2024 - Maritime Reporter and Engineering News page: 39

)

April 2024 - Maritime Reporter and Engineering News page: 39Tech Files Latest Products, Systems and Ship Designs “Wall Climbing Robot” Danish Pilot calls gets ClassNK Nod LEGO Model "A tribute build to a work life at sea" Image courtesy MOL, Sumitomo Heavy Industries lassNK granted its Innovation Endorse- Image courtesy Espen Andersen/DanPilot ment for

-

)

April 2024 - Marine News page: 39

)

April 2024 - Marine News page: 39but also cy) of the total construction timeline. coating before launch are critical for solidi? es a shipbuilder’s competitive both aesthetics and corrosion protec- edge in the dynamic maritime con- 2. Module assembly and painting: A tion. Ef? ciently managing this stage struction industry. strategic

-

)

April 2024 - Marine News page: 38

)

April 2024 - Marine News page: 38, integrated 3. Small parts approach. This intricate process, essential for achieving 4. Painting of erection joints at the module level top-tier corrosion control, is methodically segmented into 5. Final paint and ship’s completion. ? ve crucial stages: Each stage is crucial in its own right but

-

)

April 2024 - Marine News page: 34

)

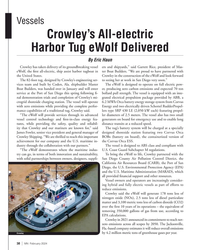

April 2024 - Marine News page: 34Feature Electric Tugs All images courtesy Eric Haun The eWolf’s power integrates into eWolf features a 6.2 MWh Orca ABB’s DC grid architecture, which battery energy storage system distributes to all the consumers from Corvus Energy. throughout the vessel. 12 to 16 inches. If you’ve got 14 inches and

-

)

April 2024 - Marine News page: 24

)

April 2024 - Marine News page: 24Feature Navigation cables, 9 miles of cables connecting substations and up to blurred, undependable information for vessel crews. two export transmission cables with “associated secondary In the fairways Notice, the USCG references the NAS cable protection” (text is from the permit) within a 42-mile-

-

)

February 2024 - Maritime Reporter and Engineering News page: 17

)

February 2024 - Maritime Reporter and Engineering News page: 17METHANOL STORAGE provals from other classi? cation societies are ongoing, said Lilp, – including accommodation.” although he acknowledges that journey from AiP to full class ap- As of September 2023, methanol had been speci? ed for 216 proval is substantive. In an area where the regulations underlying

-

)

February 2024 - Maritime Reporter and Engineering News page: 16

)

February 2024 - Maritime Reporter and Engineering News page: 16injected polymer also creates oxygen-free condi- ton, it takes 2.4 times more methanol to generate the equiva- tions behind the steel plates to prevent corrosion. lent energy as HFO. The SPS sandwich panel system can be used in lieu of coffer- Conventionally, tanks storing low ? ashpoint fuels on board

-

)

February 2024 - Marine News page: 38

)

February 2024 - Marine News page: 38Vessels Crowley’s All-electric Harbor Tug eWolf Delivered By Eric Haun Crowley has taken delivery of its groundbreaking vessel ers and shipyards,” said Garrett Rice, president of Mas- eWolf, the ? rst all-electric, ship assist harbor tugboat in ter Boat Builders. “We are proud to have partnered with the

-

)

February 2024 - Marine News page: 26

)

February 2024 - Marine News page: 26Feature Passenger Vessel Safety ume is even more eye-opening. The trade association In- ect seeking to signi? cantly reduce the risk of ? res on board terferry, which represents ferry operators and businesses ro-ro (roll on–roll off) ships. Corrigan said that Interferry’s worldwide, calculates that

-

)

February 2024 - Marine News page: 19

)

February 2024 - Marine News page: 19ment, work processes and technology progress, and it can if you start the new year out by listening to your workforce be hard to keep up with the latest changes. In 2024, keep and implementing necessary changes to work practices an eye out for updates to existing standards and implement based on their

-

)

February 2024 - Marine News page: 8

)

February 2024 - Marine News page: 8By the Numbers © Dragon Claws / Adobe Stock Rebuilding the Foundations of US Offshore Wind By Philip Lewis, Director of Research, Intelatus Global Partners As we enter a New Year, the memories of the shocks to with a potential of 3.3-6.3 GW in Delaware and Chesa- the foundations to the U.S. offshore wind

-

)

January 2024 - Marine Technology Reporter page: 52

)

January 2024 - Marine Technology Reporter page: 52? re safety of SLIC Technology. Images courtesy Engineered tion to the electronics chassis and circuit boards. Fluids Inc. Elimination of component corrosion. Immersed in a dielec- tric ? uid, corrosion cannot occur. Electronics Cooling Moisture displacement. Condensation in humid environ- Electronics

-

)

January 2024 - Maritime Reporter and Engineering News page: 21

)

January 2024 - Maritime Reporter and Engineering News page: 21, “Salt can work its way in anywhere,” said Hanning. “The and I’m proud the coatings play a vital role.” coating puts us in a winning position against corrosion.” Applicators sprayed the two coats over an SSPC-SP 10 Figure 7. The M/V Mark W. Barker – blast to the tanks. After a one-year survey, no signs

-

)

January 2024 - Maritime Reporter and Engineering News page: 20

)

January 2024 - Maritime Reporter and Engineering News page: 20of the cargo holds. A versatile two-compo- tunnel’s ? oors and walls, showcasing its versatility and effec- nent, modi? ed epoxy coating, it combats corrosion and excels tiveness in addressing the boat’s speci? c challenges. in both saltwater and freshwater environments. The coating also “Cargoes are

-

)

January 2024 - Maritime Reporter and Engineering News page: 19

)

January 2024 - Maritime Reporter and Engineering News page: 19delivers exceptional performance the hull, with an average dry ? lm thickness (DFT) of 18 mils per and protection with its high zinc content, offering corrosion www.marinelink.com 19 MR #1 (18-33).indd 19 1/8/2024 11:09:49 A

-

)

November 2023 - Marine Technology Reporter page: 21

)

November 2023 - Marine Technology Reporter page: 21The REPMUS Exercise 2023 took place between September 11- 29, 2023 at the Portuguese Navy’s Operational Experimentation Center in Tróia and Sesimbra Navy facilities. The NATO Maritime Geospatial, Meteorological and Oceanographic Centre of Excel- lence directly supports the Portuguese Navy during this

-

)

November 2023 - Marine Technology Reporter page: 20

)

November 2023 - Marine Technology Reporter page: 20EYE ON THE NAVY NATO GAINS EXPERIENCE WITH UNMANNED SYSTEMS All photos courtesy NATO By Edward Lundquist allies and partners have taken Messenger is in its second year. Both are conducted at the Navy advantage of recent demon- Operational Experimentation Centre in Tróia, one of two Por- NATO strations

-

)

December 2023 - Maritime Reporter and Engineering News page: 38

)

December 2023 - Maritime Reporter and Engineering News page: 38G REAT of BERLIN EXPRESS HIPS S 2023 Photo courtesy Hapag-LLoyd BERLIN EXPRESS SERI DAMAI Hapag-Lloyd welcomed Berlin Express into its ? eet, the MISC welcomed two of its latest new generation of Lique- ? rst ship of its new Hamburg Express class and the ? rst of a ? ed Natural Gas (LNG) carriers