DECK MACHINERY/ CARGO HANDLING EQUIPMENT

—A Review— Faster turnaround in port means increased profits for all vessel operators.

To meet that need, designers and manufacturers of cargo handling equipment and access and stowage systems continue to improve their products and to introduce new, more efficient cargo gear and deck machinery.

The editors of MR/EN asked the manufacturers of cargo-handling and other deck machinery and fittings to tell us about their product lines and their latest developments.

The review that follows is based upon the replies we had received at press time.

Literature describing all of the equipment featured in this review is available free of charge from the manufacturers.

FOR MORE INFORMATION If you wish to receive additional information and literature on any of the companies and products featured in this article, circle the ap- propriate number(s) on the Reader Service Card in the back of this issue. If you wish to receive information from all of the suppliers mentioned in this review, C i r c l e 1 1 o n Reader S e r v i c e Card AMHOIST Amhoist, American Hoist & Derrick Company of St. Paul, Minn., has announced the recent sale of a 3,000-ton-capacity revolving crane to Jardine Offshore Contractors, Inc. This order will add more than $9 million to Amhoist revenues during the next 18 months. The Model M-3000 crane will be totally designed by Amhoist, and is destined for mounting on what will be the world's largest combination pipe-lay and crane barge of monohull design.

Robert H. Nassau, president and CEO of the St. Paul Company, feels that this and other recent orders for offshore revolving cranes indicate a turning point in the demand for energy-related heavy equipment.

"We believe that as the search for oil moves into deeper and more remote waters, there should be even greater demand for large-scale, custom- engineered systems of this kind. We anticipate that the market will be entering an expansion phase again in 1986 or 1987, and that Amhoist will be participating in a number of multimillion-dollar projects in the years to come," he said.

The M-3000 crane will have a boom 315 feet long, and a revolving bearing base 78 feet in diameter.

Approximate dimensions of the barge, tentatively named Arran by Singapore-based Jardine Corporation, will be 540 feet long, 160 feet wide, and 34 feet deep. Also included in the Jardine order is a conventional American 165-ton-capacity crawler crane for use on the deck of the barge.

Amhoist designs and builds standard marine cranes in capacities from 30 to 3,000 tons, and bigger sizes can be custom-engineered for specific applications. Products range from huge barge- and shipmounted revolvers to the Sea Horse pedestral crane for materials handling on offshore oil rigs. Amhoist also manufactures American stiffleg derricks in many sizes and configurations for use on ships, barges, and platforms.

For more information, C i r c l e 12 o n Reader S e r v i c e Card APPLETON MARINE Appleton Machine Company's Marine Division in Appleton, Wise., designs and manufactures a wide range of marine cranes, winches, and deck machinery that meet the requirements of the U.S. Coast Guard and the major classification societies.

The elctro-hydraulic, self-contained winches have line pulls of up to 140,000 pounds at infinitely variable speeds. They can operate as automatic constant-tension units or can be switched to manual control as required. Both modes can be achieved at the winch or in a central control room. The winches provide greater flexibility in that both the line pull and line speed are variable from zero to maximum in any combination.

Appleton has also added hydrographic launch and recovery systems to its extensive product line, which includes offshore mooring and anchor windlasses, oceanographic winches, deck fittings, knuckleboom cranes, diving support winches, and mooring systems control consoles.

For further information, Circle 14 on Reader Service Card ASEA ASEA, Inc. of White Plains, N.Y., markets its Optitrim system that is designed to help plan cargo loading, fuel oil and fresh water bunkering, and the correct positioning of ballast in order to obtain maximum fuel savings. The company reports that this system will increase operating efficiency substantially, reduce costs, and pay for itself in less than a year.

The Optitrim indicates the most efficient mode of operation at every speed and load condition, showing basic optimum and actual figures. It can calculate cargo in each hold, in percent, volume, or weight. The unit provides optimum trim calculations when the estimated average speed is used as input. It then calculates the optimum trim for the mean draft and presents the optimum fuel savings in tons per day when the ship is retrimmed to its optimum.

The operator can shift cargo from one hold to another and immediately read off the differences in fuel savings by doing so. Every factor that affects the trim is taken into consideration.

For further information and a free color brochure, Circle 15 on Reader Service Card BEEBE Beebe International, Inc. of Seattle recently introduced its S-Core spark- and corrosion-resistant line of manual chain hoists and trolleys.

This product line is said to provide maximum protection in corrosive or explosive atmospheres—hazards that are commonly found in marine environments and applications.

Two types of S-Core hoists are available, one with an exclusive copper plating process applied to the hooks and trolley wheels, and another utilizing solid bronze components in the same areas. The load chain is nickel-diffused, greatly adding to the life and spark-resistance of the overall unit.

Beebe has developed these special hoists well beyond the traditionally available capacities, and can now offer hoists from '/, to 15 tons as standard and up to 50 tons on special order.

Beebe also offers a series of highcapacity chain hoists that represent an important advance in the airpowered hoist field. These hoists range in capacities from 10 to 50 tons, and are powered by radialpiston air motors that provide increased reliability and longer life.

Primary applications for this hoist include blowout preventer handling systems for the drilling industry and individual hook mount units for the shipbuilding and ship repair industries.

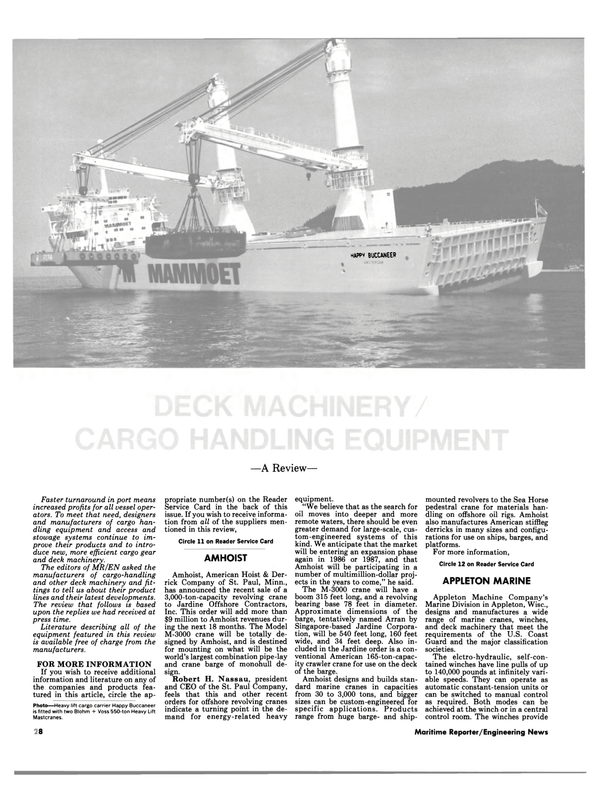

For further information on Beebe products, Circle 16 on Reader Service Card BLOHM + VOSS What is said to be the most powerful heavy lift ship in the world, the Happy Buccaneer, was delivered recently by the Innoshima yard of Hitachi Zosen Corporation in Japan.

Built for Mammoet Transport (Nedlloyd) of the Netherlands, the vessel is equipped with two Heavy Lift Mastcranes (HLM), a new development of Blohm + Voss of Hamburg, West Germany. Each crane has a lifting capacity of 550 tons, and operated in tandem they can lift loads of 1,100 tons at an outreach of 35 meters (about 115 feet).

Unlike conventional cranes, the derrick of the HLM type slews around a fixed mast. Because of this design, the mast diameter as well as the diameter of the slewing bearing can be relatively small, thereby reducing the deck space required.

The HLM's design and its arrangement at the starboard side of the ship makes it possible to provide a continuous and very wide hatch opening for bulky heavy lifts. At sea the derricks will be lashed in a nearly vertical position, permitting the carriage of bulky deck cargoes.

For handling light cargo and for rigging the hook on the slings for heavy lifts, a trolley is arranged at one side of the derrick. Its capacity is 25 tons, and it can operate in all topping angles of the derrick.

For additional information on the HLM units, Circle 17 on Reader Service Card BRADEN WINCH Braden Winch Company of Broken Arrow, Okla., is now marketing its second generation of planetary hoists. Designated the CH Series, they have capacities from 15,000 to 23,000 pounds and are offered with four motor options—three singlespeed motors and the Braden twospeed motor. The motors have improved starting efficiencies to 84 percent, and the two-speed unit can be shifted on the fly.

The following features have been incorporated in CH Series: lower minimum motor speeds—200 rpm for the single-speed motors and 150 rpm for the two-speed motor; antifriction bearings throughout, which improve the hoists' starting efficiency (less motor) to 93 percent; longer life; longer duty cycle; smoother spooling; reduced noise level; improved brake valve stability; improved brake clutch assembly; and faster line speeds.

The accessibility of motor bolts, brake discs, wire rope anchor, and fill, level, and drain plugs makes the CH Series hoists easier to service and maintain. Maximum interchangeability of parts results in lower parts inventory to service all hoists in the series.

For more information on Braden hoists, Circle 18 on Reader Service Card JERED BROWN BROS.

Jered Brown Brothers is a major supplier of deck machinery and other marine equipment worldwide.

Products include anchor windlasses and capstans, non-magnetic minesweeper deck machinery, cranes, steering gears, elevator systems, main thrust bearings, and line shaft bearings. Jered equipment is specified on FFG 7, CG 47, LSD 41, LHD 1, MCM 1, T-AO 187, T-5, and CVN Class vessels and many other commercial ships.

In addition to providing equipment on new ship construction, Jered provides spare parts and maintenance on deck machinery in service. Jered has engineering drawings and parts for equipment manufactured by American Engineering, C.H. Wheeler, Baldwin-Lima-Hamilton, and Jered Industries.

For additional information, Circle 3 1 on Reader Service Card CATERPILLAR Caterpillar has introduced the V925 lift truck designed to meet the needs of the worldwide containerhandling industry. The V925 has 75,000 pounds of capacity when equipped with a container-handling spreader for moving and stacking fully loaded 20- to 40-foot containers at dockside, rail yards, and transfer terminals. It is the largest in the Caterpillar Lift Truck product line.

Among the V925's special features is the oil disc brake system.

The multiple disc design provides significantly more braking surface than standard shoe-type or dry caliper disc brakes. The result is excellent response and extended brake life, up to 15,000 hours under continuous operation. Dual 21:00 by 35 drive tires and single 18:00 by 33 steer tires, the largest offered in the industry for this size class, provide a large contact area and low ground pressure for long life.

The V925's Cat planetary power shift transmission—currently used in large Cat wheel loaders—has four speeds forward and reverse for the varying conditions required in container handling. The transmission can be shifted at speeds up to 5 mph without potential damage or shortened life. Another feature is an integral steer axle/counterweight. The entire rear section oscillates about the main frame, providing low rear profile for superior visibility and lateral stability.

The V925 cab, with pilot-operated hydraulic controls, provides for operator comfort and high performance under full work demands and extended shifts. The cab is center- mounted for optimum visability front, rear, and sides.

For further information on Cat lift trucks, Circle 19 on Reader Service Card CLYDE Clyde of Duluth, Minn., a unit of AMCA International Corporation, has redesigned its popular line of medium-capacity winches, the frame 4 through frame 8 series, achieving greatly improved performance ratings in anchor/mooring services.

This winch series spools wire in %- through 1 Vi -inch diameter and exceeds first layer stall pulls in excess of 50,000 pounds. The winches may be powered by diesel or gasoline engines, or electric or electrohydraulic motors. They are available as single-drum units, or as two-, three-, or four-drum units in waterfall configurations. For effective corrosion resistance, the winches are prime coated with inorganic zinc paint, with a finish coat of marine epoxy enamel.

The available free literature on Clyde frame 4 through frame 8 winches includes data on wire rope sizes, drum dimensions, spooling capacities, drum clutch and brake specifications, as well as dimensional drawings and typical performance data for anchor/mooring service.

These Clyde winches are available throughout the U.S. from Hydraulic Power Systems, Inc. of Kansas City, Mo. In addition, HPS handles Clyde barge movers and car pullers, and offers full service in every phase of the business—sales, rentals, parts, and service.

For further information and literature, Circle 20 on Reader Service Card CONMACO Amcon air-controlled hoists are an exclusive with Conmaco, Inc. of Kansas City, Kan. The flagship of the line is the Amcon 6250, which handles up to 12,000 feet of 3-inch wire rope.

Also new to the 7-hoist Amcon lineup is the Amcon 150. This versatile hoist will handle wire rope up to 1-inch and delivers up to 35,000 pounds of line pull. It has proved itself to be well-suited for anchorhandling applications on small vessels and supply boats, or for mooring small barges on inland waterways.

Conmaco also recently introduced a line of deck-mounted fairleaders, each with the rugged construction to withstand the breaking strength of indicated wire rope. Bearings in the barrel and sheaves are engineered for long life and dependability, even under rapid or severe changes of lead.

New to the Amcon line of winches is the 20C hydraulic winch with a line pull of up to 40,000 pounds (1- inch wire rope) and spooling capacity of 1,434 feet. An important feature of this winch is that each drum is fitted with a friction clutch allowing the drums to "free wheel" independently.

In addition to a full line of aircontrolled winches, fairleads, deck guide sheaves, and chain handling equipment, Conmaco also offers rental, sales, and service on hydraulic continuous pull machines with CPL as high as 1.5 million pounds.

For further information, Circle 2 1 on Reader Service Card CROSBY GROUP A 180-page, full-color catalog is available from The Crosby Group, a Division of Amhoist, which is comprised of Laughlin®, Lebus®, McKissick, National, and Western.

The companies manufacture every conceivable kind of fittings and accessories for deck machinery, cargo handling and other applications, including forged fittings, hooks, blocks, sheaves, pulleys, load binders, chain, etc. The catalog describes all of the products of all divisions in full detail with photos, detailed drawings, all measurements, and full specification charts.

McKissick products, a division of the Crosby Group in Tulsa, Okla., now has new roll forged sheaves available in the most complete range of sizes from 12 through 72 inches. The sheaves are an ideal choice for original equipment in self-unloading systems and as replacements.

McKissick sheaves are forged from controlled quality 1035 carbon steel which provides excellent welding and flame hardening characteristics.

All incoming steel is tested by chemical and spectrograph^ methods to insure consistently high quality.

Steel sheaves have excellent flexibility when choosing bearings and also provide better cold weather properties than nylon sheaves.

Crosby links and rings are manufactured in a complete line of sizes and types for almost any application, with working load limits from 1,600 to 232,500 pounds.

Lebus products include lever and ratchet type load binders, grab hooks and tail chains, snatch blocks, and hook latch kits. McKissick specializes in custom designed blocks to any specification, oil field blocks, crane and hook blocks, overhaul balls, swivel hooks, and snatch blocks, as well as many other products.

Western manufacturers sheaves and sleeves, wood and steel blocks, and cargo blocks and fittings, just part of its extensive product line. National's product line includes steel swaging sleeves, duplex sleeves, swage buttons and furrules, as well as swaging presses in capacities from 500 to 3,000 tons.

For a copy of the Crosby catalog, Circle 22 on Reader Service Card EMMI-PUSNES Pusnes was founded in 1875 as a shipyard and started deck machinery production in 1890.

Today, Pusnes is one of the few companies in the world concentrating on the development and manufacture of all types of deck machinery for mooring systems used on a broad range of floating equipment.

When you board a 540,000-dwt ULCC you will find Pusnes steam deck machinery. Looking closer at the windlass on any of these large tankers you will notice up to 1,000- hp disc brakes used to drop the anchors under finger tip control.

Visit a semisubmersible on a drilling station and you will find Pusnes mooring systems for chain, chainwire combo, or all-wire and moored in depths up to 3,500 feet. Systems for greater depths and hostile environments are under development today.

Pusnes also manufactures mooring equipment for smaller coastal ships, barges, tugboats, off-shore supply boats, pipe-laying barges, and similar vessels.

Minimum crew and safety are Pusnes trademarks. The unique roto-bollard for mooring rope handling is a typical innovation.

Mooring systems for chain, cable, and rope employ steam, electric, or hydraulic drives. The equipment can be local or remotely controlled and, when necessary, the mooring forces constantly monitored.

Pusnes is part of "SUBTECH" Norway, a firm developing complete diving systems which employ diving bells, underwater vehicles, bell winch systems, divers gas recovery systems, external life support systems, and the "Hyperbaric" saturated divers lifeboat. Concern for offshore personnel resulted in the development of "Pudes," the controlled extendable protected gangway for dry evacuation.

Pusnes has a joint venture company in Japan, Nippon-Pusnes, and both are represented in the U.S. by EMMI Corporation, of Flemington, N.J.

For further information, Circle 23 on Reader Service Card GEARMATIC Gearmatic Company of New Westminister, B.C., Canada, a division of Paccar of Canada, Ltd., has pioneered many new features in hydraulic winch design such as planetary gearing, totally enclosed construction, automatic breaking, sin- gle lever control, mechanical twospeed, and free fall.

Every Gearmatic hydraulic winch and hydraulic drive is virtually custom- built to meet specific performance needs, based on proven modular designs and assembled at the factory from a wide selection of optional features. Representatives of the range of offerings is Gearmatic's model 54 three-speed hydraulic planetary hoist. The model 54 provides speed and flexibility in operation without sacrificing the qualities of simplicity, dependability, and long-life that are hallmarks of Gearmatic.

The model 54 features line pulls up to 56,000 pounds, line speeds of up to 474 fpm, a three-speed power shift, gear changes that can be made under load and with the cable drum in motion, built-in automatic safety brake, and the complete drive train totally enclosed, sealed, and running in oil. Options include various cable drum sizes, hydraulic motors, gear ratios, and Gearmatic's freefall capability.

The model 54 is a result of Gearmatic engineers sophisticated testing both in the lab and in the field that proves out new designs, refines production models, and develops new applications for many industries— including fishing, off-shore exploration, oil and gas pipeline, marine, and dock installations.

Gearmatic hydraulic winches and drives are sold and serviced throughout the U.S., Canada, and worldwide through a network of distributors convenient to maritime centers. They offer technical assistance, service, and parts.

For additional information, Circle 25 on Reader Service Card FMC A 22-page full-color guide describing Link-Belt's crane and excavator line is being offered by FMC of Bannockburn, 111.

The guide discusses FMC's crane operations, engineering and research programs, and the manufacturing and testing programs for structures and components. Within each of eight categories of Link-Belt cranes, such as pedestal mounted hydraulic offshore cranes, is a model number and specifications. The specifications include capacity stated in tons and metric tons; capacity at 50-foot radius; maximum crane boom; main drum line pull/ line speed for three speeds; and overall length, width, and working weight.

FMC has added a 33-ton (29.93 mt) capacity API-65 to its Seahawk series of Link-Belt® hydraulic offshore cranes. The lightweight 25,000-pound API-65 is specially designed to perform all the material, equipment, and personnel lifting required on offshore oil production platforms and drilling rigs, and meets API-2C (1982) specifications.

The API-65 features pin-connected components that permit fast modular erection and easy maintenance.

The heaviest component weighs just 7,200 pounds. The compact design features a 7-foot 7-inch tailswing with onboard engine and cab, and an overall height of 14 feet 7 inches reducible to 8 feet.

A maximum API rating of 34,200 pounds is achieved with a 50-foot boom at 30-degree radius, best in its class. Superior load handling speed is provided by a matched engine, 3- section pump and winch combination that develops 300-450-fpm maximum line speed with 12,600- pounds maximum line pull on main or auxiliary drums. A horsepower limiter prevents engine stalling due to excessive loads.

For a copy of the guide and further information, Circle 24 on Reader Service Card HAGGLUNDS The low-speed, high-torque camring motor first introduced by AB Hagglunds & Soner of Sweden more than 25 years ago has had considerable impact on marine and industrial drive applications. This is because it closely meets several important requirements such as high starting torque, easy speed regulation, inherent overload protection, suitability for direct drive thus eliminating gears, compactness, low weight-to-torque ratio, and the ability to withstand the worst marine and industrial environments with little or no maintenance.

Besides winch drives of many kinds, these advantages are of course very attractive in deck cranes. A major commitment to hydraulic deck cranes is one of the features of the current U.S. Navy program to strengthen the Rapid Deployment Force (RDF) of the Military Sealift Command. Hagglund hydraulic cranes are being installed on all 21 of the sophisticated RO/ RO-LO/LO vessels in the RDF program— a total of 99 units.

The RDF program comprises 13 Maritime Prepositioning Ships (MPS) and eight Fast Logistic Ships (T-AKR), the latter being the 33- knot SL-7 containerships purchased by the Navy from Sea-Land in 1982 and being converted by Avondale Shipyards, National Steel and Shipbuilding, and Pennsylvania Shipbuilding.

Four of the eight former SL-7s have already been delivered to the Navy. Each of the T-AKRs have one twin 35-ton crane and one twin 50-ton crane.

Of the Maritime Prepositioning Ships, the five being converted by Bethlehem Steel for Maersk Line will each have one twin 36-ton crane and two twin 30-ton cranes, the three being converted by NASSCO for Waterman Line will have one twin 50-ton crane and one twin 35- ton crane per ship, and the five new buildings for General Dynamics under construction at its Quincy yard will each have two twin 39-ton cranes and one single 39-ton crane.

These Hagglund cranes will be capable of combination operation to handle loads up to 100 tons under a single coordinated control. The requirement to be able to work cargo safely under open-sea conditions was a special feature of these contracts.

Deliveries of these cranes are reported to be proceeding to the full satisfaction of the shipyards involved.

For additional information, C i r c l e 2 6 o n Reader S e r v i c e C a rd HIAB HIAB Cranes & Loaders, Inc. of York Pa., offers five models of its well-known hydraulic deck cranes.

Features and capabilities of HIAB Sea Cranes include ease of operation, light weight, maneuverability, load control and precision placement, compactness, low operating height, horizontal outreach and load carrying capacity, and corrosion resistant construction.

Trim and compact in design, they do not require guide ropes, cables or hand-operated winches to handle.

They take up little space and can be mounted anywhere on a boat deck.

HIAB cranes are easily operated by one man using positive, direct hydraulic controls. The crane's movements are fast and smooth due to the high-pressure hydraulic system.

On smaller boats, the lightweight feature permits a bigger cargo payload.

The cranes have a flexible elbow between the main boom and outer boom, and a telescoping extension boom. (The cranes rotate up to 410 degrees on some models.) These features provide exceptional maneuverability and the capability for lifting heavy loads close in or at maximum horizontal reaches. Outer booms provide a firm, rigid support for the cargo hook. In conjunction with the flexible elbow, this provides steady load control and the ability to precisely spot the load.

The cranes fold down into a compact configuration with a low center of gravity that will not affect vessel stability and provides more cargo space on the deck.

HIAB hydraulic cranes are specifically manufactured for maritime use. Protection against sea and salt corrosion is ensured by the extensive use of galvanized components, waterproof fittings, nickel chromeplated boom cylinders, and special marine coatings.

For further information, C i r c l e 2 7 o n Reader S e r v i c e Card HYDE PRODUCTS Hyde Products, Inc. is a leading supplier of ship deck machinery and steering gears, serving the marine industry since 1865. Originally founded as the Hyde Windlass Company in Bath, Maine, today the company is headquartered in Cleveland.

Equipment manufactured includes steering gears, steering systems, vertical and horizontal anchor windlasses, constant-tension mooring winches, cargo winches, specialpurpose winches, capstans, mooring chocks, vacuum and compressor systems, and oil/water separators.

While Hyde has a standard product line, custom-designed machinery is its specialty.

During the past three years, Hyde has delivered a series of steering systems and windlasses to the South Korean Navy. The contract was for the design and manufacture of steering systems, rudder angle indicating systems, and vertical anchor windlasses for Navy corvettes (KCX) and frigates (KFX) being built in South Korea. The anchor windlasses are single wildcat vertical types powered by multispeed electric motors through triple reduction gearing. These units feature a low above-deck profile, with the speed reducer, motor, brake, clutch, and controls below deck, protected from the environment.

The corvette steering gears are of the basic two-cylinder link type, but the power and control units are a significant departure from the conventional steering system. Through the innovative application of modern electronic and fluid power technology, many of the traditional intricate and cumbersome mechanical components have been eliminated.

The net result has been a significant reduction in cost and weight, without the sacrifice of operational performance or reliability.

Hyde recently received orders for the first of two new classes of vessels to be built in Korea. The company will build an anti-magnetic anchor windlass for a Mine Hunting Craft (MHC) and the steering gear, anchor windlass, and capstan for a Police Corvette. These two new contracts bring the total of Koreanbuilt vessels supplied with Hyde equipment to 19. Negotiations are currently under way for additional KCX vessels to be delivered in 1985.

For additional information, C i r c l e 2 8 on Reader Service Card A.C. HOYLE The A.C. Hoyle Company of Iron Mountain, Mich., has been a major supplier of deck machinery to the marine industry for nearly a quarter of a century. The company offers a complete line of deck equipment including anchor windlasses, constant- tension mooring winches, mooring winches, topping and vang winches, towing winches, fairleads, chocks, and bitts to both the naval and commercial marine markets.

Though equipment can be built to numerous standard designs, Hoyle specializes in custom building to customer specifications. Company personnel are available to assist customers from preliminary design states through final design, installation, and testing. Major considerations are given to providing the best equipment available to meet the customer's requirements and at affordable and competitive prices.

Winches, windlasses, capstans, and cranes are available with allelectric, electro-hydraulic, hydraulic, static dc, or diesel drives. All deck equipment, including fittings, are available in conventional steel construction as well as stainlesssteel and aluminum.

For additional information, C i r c l e 2 9 on Reader Service Card INTERCON Intercontinental Engineering- Manufacturing Corporation (INTERCON) of Kansas City, Mo., has recently added to its existing product line of large towing and mooring winches a series of smaller waterfall configuration mooring winches.

The new series of winches are intended for the requirements of barge and supply vessel mooring needs in the construction and oil field markets. Power source options include diesel, hydraulic, and electric— all designed specifically for the offshore environment. The winch series will handle mooring lines ranging from IVs inch diameter thru 1% inch diameter. The units are available for lease or immediate purchase.

For further information, C i r c l e 3 0 on Reader Service Card KOCKS CRANE/ SALZGITTER GROUP Having established itself as a designer and constructor of container cranes for seaports, the Kocks Crane and Marine Company (KCM) of Pittsburgh, Pa., has concluded an agreement with one of the Salzgitter Group of companies for supplying all of its bulk materials handling products for the U.S. market. The new venture will be identified as Salzgitter-Kocks Bulk Systems and will operate as a division of KCM.

Market areas being looked at are seaports, inland terminals, utilities, and general bulk commodities terminals including cement and grain industries. The company's diverse product line includes every conceivable material handling and storage system . . . pneumatics, belt conveyors, mining, ship loading/unloading, indoor storage, and stacking and reclaiming.

Other equipment available from Salzgitter-Kocks includes a complete line of bulk handling equipment including stackers, stackerreclaimers, scraper reclaimers, clamshell, pneumatic, continuous ship and barge unloaders, buckets, grabs, and coal blending systems.

The company has expertise in the handling and processing of lignite, coal, potash, cement, alumina, silica, phosphate, and other commodities.

Design, supply, and construction is available for equipment and facilities.

For additional information, Circle 32 on Reader Service Card LAKE SHORE Among the noteworthy applications of deck cranes from Lake Shore, Inc., Iron Mountain, Mich., were the cranes installed on the Moore McCormack Lines ship conversion performed by American Ship Building, Tampa, Fla., and Lorain, Ohio Divisions. These cranes, rated at 40 metric tons at 65.5 feet radius, are all-electric, utilizing solid state SCR-controlled General Electric D.C. drives. They have both wide boom tips and tagline winches to reduce load pendulation and were manufactured in Iron Mountain under license from Clarke Chapman Marine—U.K. The first shipset of three cranes was designed and delivered in less than 12 months.

In addition, Lake Shore designs and manufactures a full line of deck machinery, including mooring, cargo, hose, topping, anchor handling, and traction winches; anchor windlasses, life-boat davits; and cranes for cargo handling, hose and stores handling for ocean, Great Lakes, offshore or Navy applications.

Types of drive systems supplied include hydraulic, electro-hydraulic, diesel, static D.C., wound roto A.C., and variable frequency A.C.

Lake Shore specializes in custom designed machinery to meet customer specifications.

For additional information, Circle 33 on Reader Service Card MacGREGOR-NAVIRE INTERNATIONAL Formed following the acquisition of MacGregor Internationl by Kone Oy, of Finland, which already owned Navire Cargo Gear International, this new company is a major force in the area of cargo access equipment and systems.

Both partners have developed numerous designs of specialized equipment including, in the area of deck machinery, all manner of hatch covers.

The range of covers designed vary from units for the largest bulk, OBO, and ore/oil carriers down to the smallest inland waterway vessel.

Recent innovations for folding covers on medium sized vessels have included the self-engaging auto cleat and the gravity cover. The selfengaging auto cleat system uses angular interlocks, or wedges, on the cover side/coaming and at the cross joints to form the cleats. It has been incorporated in the "Direct Pull," "Foldtite," and "Foldlink" cover designs.

The recent entry into service of Atlantic Container Line's containerroll- on/roll-off (CONRO) vessel Atlantic Companion also marked the introduction of the first full outfit of MacGregor-Navire's StackCell weatherdeck cell guide system. The new ship was built by Kockums for the account of Transatlantic AB, one of the three Swedish partners in the ACL consortium.

MacGregor-Navire lists the advantages of the new StackCell system as follows: • Increased number of fully loaded containers that can be loaded in one stack.

• Wide flexibility in container stowing distribution.

• No loose lashing, twist locks, or joining cones required.

• Elimination of any manual lashing.

• Risk of accidents minimized.

• No need for checking or retightening of lashing during sea voyage.

• Quicker placing or "spotting" of containers.

• Handling operations can start without any preparation or unlashing work.

•No waiting for intermediate lashing or work after completion.

• Easy and safe access to reefer containers.

These considerable advantages have been achieved after much preliminary design work and prototype testing carried out by the efforts and expertise of ACL, TransConsultants, and MacGregor-Navire.

The most obvious vessel that would gain maximum advantage from weatherdeck cell guides is the fully cellular containership. Other applications envisaged by MacGregor- Navire include the feeder ship, the bulk/container carrier, the open bulk carrier, and the whole spectrum of CONRO, RO/RO, and RO LO designs.

For further information on the StackCell system.

Circle 34 on Reader Service Card MARATHON LETOURNEAU Marathon LeTourneau Company introduced a new line of marine pedestal cranes with solid-state electronics at the Offshore Technology Conference last year. The three new cranes are the 50-ton-capacity PCM-120SS, the 55-ton PCM"- 220SS, and the 75-ton PCM-350SS.

All three can be with standard and optional features that can tailor the cranes to perform all lifting requirements for materials, equipment, and personnel on offshore drilling and production platforms.

These cranes have a single ac power source rather than a motor/ generator arrangement; microprocessors control power flow to all drive motors. As each electric motor is individually and precisely controlled by solid-state technology, the new cranes function with a high degree of efficiency, offer faster lifting speeds with loads, and feature smoothness of operation. The solidstate controls also provide precise control of current flow, voltage, and operating temperatures. These features translate into extended service life and minimum maintenance for motors, gears, and other moving parts.

Electrical power requirements are the same for the three units: standard commercial, 600-volt, 60- Hertz, 3-phase, 500-amp external supply. An integrated, solid-state silicon controlled rectifier provides dc power to each drive system. Peak power requirement under maximum load, dual function, 20-minute continuous duty with dc dynamic braking is 250 kva at 0.7 power factor.

The power system for all three cranes consists of Marathon Le- Tourneau N-7 dc electric motors with N drivers for hoist and lifting functions. A D-10 electric motor with #5 gearbox provides power for crane swing. Remote control is standard, with controls terminating at a spring-centered, infinitely variable potentiometer controller located at the operator's station. These cranes can be supplied with an operator's cab as an option.

For more information, Circle 35 on Reader Service Card M C E L R O Y M A C H I NE McElroy Machine and Mfg. Co., Inc. of Biloxi, Miss., began furnishing deck machinery to the offshore workboat industry in early 1980.

The company now has three very successful years and has machinery working in all parts of the world.

The latest additions to McElroy's standard line of anchor windlasses, anchor winches, capstans, and towing winches is a line of self-contained electrohydraulic tuggers and a line of stern rollers. The hydraulic tugger is manufactered in a 5-ton line pull model and a 10-ton model.

A 15-ton and 20-ton model are on the drawing boards for the future.

The stern rollers are manufactured as a standard model or a heavy-duty model. Custom sizes are also available upon request.

Some of the latest installations have been hydraulic tuggers aboard the last Nicor Boat built at Moss Point Marine in Escatawpa, Miss., anchor windlasses for the Gulf Fleet boats being built at St. Louis Ship, and the Gulf Fleet boats being built at Quality Shipyards in Houma, La.

Additionally, McElroy Machine furnished the capstan and vertical capstan/windlasses for the split hopper dredge built at Southern Shipbuilding, Slidell, La., and the vertical capstans for the landing craft built by Champion Swiftships of Pass Christian, Miss.

McElroy Machine has a complete engineering and design department to assist with special or custom specifications and machinery.

For additional information, Circle 36 on Reader Service Card MARCO In addition to improvements made to existing products, Marco of Seattle introduced three new pieces of fishing deck machinery recently.

First was a new aluminum longline drum, used in a variety of longline fisheries on both coasts of the U.S.

and Canada, as well as in other areas of the world. The hydraulically powered drum features gear drive that makes it powerful enough that no secondary hauler is required. The new unit also features a diamondscrew levelwind and a unique declutching motor and adjustable drag brake to control freewheeling speed.

Marco's San Diego-based subsidiary, Campbell Industries, recently introduced a long-needed product for the world's high-seas tuna purse seine fisheries. Its new purse block for large superseiners is larger and yet 50 percent lighter, at 210 pounds (95 kg), than any other block of its capacity (20T/18mt).

This new, stronger block features a spring-loaded grease reservoir to automatically maintain lubrication under load, eliminating the problem of bearing failure due to inadequate lubrication. The design also handles 1-inch (25-mm) connecting links through its throat, which are necessary to handle the heavier loads on %-inch (22-mm) purse lines with 1-inch center piece.

The most recent introduction by Marco was its unique line of Foam- Flo fish pumping systems. Designed to meet the particular needs of the salmon and herring fisheries, the FoamFlo was developed with its chief goal being fish quality. The challenge has been to develop a pump that could handle great quantities of product, and yet treat both small and large species without damage. With its unique combination of injected water and air creating flow, FoamFlo answers this important challenge.

For further information on Marco products, Circle 37 on Reader Service Card MARKEY MACHINERY With work vessel construction continuing to be slow, the challenge to maintain quality standards in the face of extremely competitive pricing remains intense. Markey Machinery Company (MMCO) of Seattle has supplied the oceanographic community with several research winches during the past year, with the focus being on the ac-SCR-dc drive systems with 50- and 75-hp output ratings. As an alternative to the variable-displacement hydraulic systems, these dc drives are proving to be energy-efficient, quiet, highly tunable, and clean, as well as providing a side speed range and excellent control.

An entire new generation of very large winches and rig anchor chain windlasses is looming as the energy industries move into deeper water where present units and their equipment are marginal or overmatched.

Anchor-handling wires of 2-%-, 2-%-, and 3-inch diameters with scopes of 3,500 to 5,000 feet are being seriously considered. Barrel-layer line pulls of from 500,000 to 750,000 pounds are required in order to offer enough working pull farther up the drum stack. Much more critical than the hoisting service is the machinery and control necessary to safely lower up to four anchors into thousands of feet of water at high speeds.

Well beyond the capability of band or disc braking systems, this duty calls for one or more of the water-cooled retarder units with pumps and heat exchangers to handle several hundred gallons per minute of fresh water. Increasing sophistication in instrumentation, alarms, and "set-point" automatic override systems will be required.

Handling rig chains with these large combination machines is facilitated by the newly patented MMCO Multi-Cat that provides sixpocket wildcats with readily replaceable inserts to accept a range of chain sizes. The vessel can operate with a variety of chains without major wildcat changeout.

Practical winch-powering systems include the 300- to 600-bhp diesel engines with torque-converter transmissions, and the 500- to 1,000-hp electrical SCR-dc drives— particularly appropriate aboard the SCR-propelled vessels. This class of machinery is so large and heavy that each unit will have to be layed out to suit the deck space for a particular vessel.

As electronics establishes that it can stand the marine environment for extended periods of years, many more applications will be seen, such as remote anchor dropping on barge windlasses, servo-controlled research winches, and greater levels of safety back-ups on the deep-water anchor-handling machines. Deck machinery remains an endeavor where new requirements, new arrangements, and new capabilities prevent efforts at standardization from taking greater hold.

For additional information, Circle 38 on Reader Service Card NABRICO An all-new electric winch designed for long life, easy maintenance and dependable service and an "easy-to-get-off" cast utility twist lock flush hatch are among the latest developments from Nashville Bridge Company (NABRICO) of Nashville, Tenn.

The electric winch is designed for use on towboats or for any sort of intermittent winching operation requiring a large holding capacity. It has a 10-ton pulling capacity and a 40-ton holding capacity.

An oversized brake ensures that the NABRICO winch will hold its rated capacity of 40-tons. And a back-up mechanical locking paw can be used to hold the rated capacity in case of brake failure. The NABRICO electric winch has a freewheeling feature to allow faster cable pull out. Ball bearings on the highspeed shaft and the precision machining of the side plates and shafts add to the overall efficiency of operation and life of the electric winch.

The winch is powered by a 5-hp motor. It requires only a simple power lead connection to begin operation.

All necessary controls are supplied by NABRICO with the winch. In addition, the company stocks all replacement parts to ensure customers minimal down time should any repairs become necessary necessary on the electric winch.

The new cast twist lock flush hatch is designed especially for use by companies involved in the transportation of solid materials, such as rock and gravel or coal. Suitable for any hopper or deck barge application, the cast hatch is sturdy, durable and easy to maintain. Its simple twist lock operation ensures that the hatch will remain easy-to-get-onand- off for many years.

With plants in Nashville and Ashland City, Tenn., Nashville Bridge Company is a major supplier of marine deck hardware to the entire marine industry. The company pioneered in the design and construction of much of the modern equipment used on rivers today.

For additional information, Circle 39 on Reader Service Card NATIONAL CRANE National Crane's pedestalmounted cranes are cost-efficient lifting systems for shipboard, dockside, and other marine uses. A wide selection of boom lengths and capacities are available from the 28- foot reach and 10,700-pound capabilities of the Marine 200 to the 75- foot length and 34,000-pound maximum capacity of the 800.

A new addition to National's already popular line of marine equipment is the 400, a medium-duty crane with lighter boom sections and increased capacity.

National Crane—continued Each crane from the Waverly, Neb.-based company is built to rigid specifications and strict quality control standards for years of profitable service in harsh marine environments.

National Crane booms are built stronger and lighter with boxsection construction of highstrength, low alloy steel to handle heavy loads. The sequential extension of the telescoping boom sections interlock for strength and long reach, up to 75 feet. All cranes are fully marine conditioned by a process that includes sand blasting of all external surfaces, an inorganic zinc primer coat, followed by paint and covered with a durable chlorinated rubber topcoat. National turret drives are specifically engineered for fast, smooth controlled slewing and minimum maintenance.

Four models of telescoping marine cranes are available to jobmatch the best crane for particular lifting needs.

The Marine 200 is an inexpensive, shorter radius machine for use on smaller boats and barges, in general purpose dockside and terminal work, and on offshore platforms.

The 200 is ideally suited for many jobs where larger capacity cranes prove inefficient, while still providing the workhorse capabilities of a reach up to 28 feet and maximum capacity of 10,700 pounds.

The National 400 and 600 series provide increased reach and capacity for bigger jobs with maximum reaches of 55- and 56-feet, and load capacities of 16,000 and 25,000 pounds, respectively.

National's 800 series offers some uniqueness in marine applications because of its four-section hydraulic extension capabilities up to 75 feet and 34,000-pound capacity. Heavyduty construction and tough planetary drive rotation mean more work-time and less down-time, even under extreme duty.

For additional information, Circle 40 on Reader Service Card NATIONAL SUPPLY A cargo-handling barge designed to accept a National Supply Company continuous lift jacking system enables the operator to readily convert the barge into a stable platform for loading and unloading. The barge uses a rack-and-pinion jacking system originally developed by National for offshore drilling and production platforms.

With the legs jacked up, the barge retains its mobility and can be easily towed between sites. Once in location, the barge is jacked up to create a stable platform at various deck levels. The jacking system, which has a smooth, continuous lifting movement, uses an arrangement of horizontally opposed pairs of pinions that provide positive engagement with a precision-cut, doublesided rack.

The National jacking system has been used in 18 different rig designs and is offered by more than 30 shipyards around the world. Literature available from National contains specifications for various unit arrangements, tensile properties for its components, and a description of other features, including pushbutton control operation and various safety features.

Individual leg control is accomplished at a central console, where the operator can operate all legs individually or simultaneously, with mixed hull-up and hull-down operations.

Each climbing pinion has an individual gear motor and gear train drive, with each motor having an electromagnetic-released, springset, fail-safe multi-disc brake.

For further information and a copy of the literature, Circle 41 on Reader Service Card NAUTILUS CRANE Nautilus Crane & Equipment Company has a modern 50,000 square-foot plant for the manufacture of high-speed cranes for shipboard and offshore drilling and production rigs. The acceptance of the Nautilus hydraulic crane designs since the company was founded in 1973 has been excellent.

Used on drilling rigs, production platforms, jackups, workboats and ships, Nautilus cranes are designed to handle loads from 2 to 100 tons.

Features include telescoping or straight booms, hydraulic diesel or electric power, and a variety of mounting and boom length options.

The Metairie, La.-based company is owned by Beckwith Machinery Company, a Caterpillar dealer serving the northwest Pennsylvania and West Virginia area from Pittsburgh.

Nautilus points out that their present manufacturing facilities occupy eight times the manufacturing space of the previous plant. The present facilities include a CAD/ CAM system for computer-aided engineering design and manufacturing.

The system provides faster crane deliveries and the ability to more easily adopt design features to special requirements. Nautilus also uses a computer to analyze a crane design to determine its ability to withstand forces it encounters in severe environments. It can take into account the effect of high winds and seas on the crane and select or modify a design to satisfy the requirements.

The new Nautilus 100-ton lattice boom crane has a structural design that aids in transforming loads to the foundation. Other features of the crane include a new type winch which has multiple braking modes, a cylindrical designed pedestal, and a small tail swing working radius.

For additional information, Circle 42 on Reader Service Card PACECO/O&K In the fall of 1982, O&K Orenstein & Koppel AG of West Germany, and Paceco, Inc., a subsidiary of the Fruehauf Corporation and one of the world's leading manufacturers of container handling cranes, agreed to cooperate in engineering and manufacturing in the U.S.

Among the products involved is the new O&K-designed doublejointed deck crane that is capable of handling cargoes—particularly containers— twice as fast as conventional deck cranes.

In addition to faster operation and greater precision, particular design emphasis was placed on improving the operator's field of vision and to reducing the overall height of the cranes to improve vision from the bridge.

The new O&K deck cranes guide the cargo loads with short pendulum movements that are absolutely horizontal as on a quay-mounted bridge. The movement is also on selectable lines transverse to the ship while the jib point turntable automatically retains its direction parallel to the longitudinal axis of the ship.

By manual control, the crane operator can additionally bring the jib point turntable into any position.

The operator's cabin, always traveling above the load, is attached under the articulated jib and, owing to ideal vision, makes it possible for the operator to handle cargo hatches or containers without assistance to guide it.

The cranes are designed with good accessibility to the machinery, electrical and/or hydraulic equipment accommodated in the jibs.

The smooth surfaces of the structure provide for easy and troublefree maintenance. Hydraulic pipes and equipment are arranged in such a way that all oil-carrying components are located inside the individual crane assembly groups.

Crane types include the BEH with electrohydraulic drive with three phase squirrel cage rotor motors, hydraulic variable displacement pumps, closed circuits, electrical controls. The crane type BEE features all-electric drive, statis transformers and DC motors.

The cranes will be manufactured at Paceco's newly expanded computer integrated facility located on deep water near Gulfport, Miss.

For additional information, Circle 43 on Reader Service Card PETTIBONE Pettibone Corporation of Chicago manufactures a full line of pedestalmounted Marine Kranes for use on docks and offshore platforms, as well as on shipboard. Capacities range from 5 to 100 tons. Hydrauli- cally extendible knuckleboom and fixed booms, both box and lattice, are available. With special features such as inorganic paint to withstand salt-laden, corrosive environments, they are built to provide years of trouble-free service.

Pettibone has been building and improving cranes for the marine industry since 1964, so built-in features are the result of more than 20 years of design work. Today, as part of a continuing research and development program, the company has a list simulator for safety testing of cranes manufactured for shipboard applications.

The Solus vessel Tengar, one of a fleet that services Royal Dutch Shell offshore drilling platforms in the South China Sea off the coast of Borneo, is equipped with a model 40 PMp Pettibone Marine Krane.

Mounted on the main deck forward of the hatch, the 40 PMp provides needed reach with a 110-foot boom and 360-degree rotation. Its remote power pack is installed below deck, and controls are within easy reach of the operator, whose cab provides full view of the work area. Like all Pettibone pedestal cranes, the PMp 40 is available with American Bureau of Shipping certification.

For additional information, Circle 44 on Reader Service Card RAYTHEON OCEAN SYSTEMS Raytheon Ocean Systems Company of East Providence, R.I., manufactures the LOADMAX® multipoint digital loading computer that is designed to aid ships' officers in planning safe, optimum vessel loading.

The front panel display of the desk-top unit is readily configured for any type ship. Information on draft, stability, and hull stresses for any loading condition can be calculated quickly and accurately.

Several models are available according to need. The Loadmax 100 computer performs draft, shear force, and bending moment calculations only, and is intended for carriers where stability computations may not be required.

The model 200 unit performs stability calculations, as well as those for draft and hull strength. Special programs are available for LNG and LPG ships, integrated tug/barge units, and containerships.

The Loadmax 300 computer provides for cargo specific gravity entry, cargo volume entry with automatic conversion to weight, and automatic variable VCG and free surface corrections for carrying levels in cargo, ballast, and fuel oil tanks.

For integrated tug/barge systems, the Raytheon computer can provide calculations for tug alone, barge alone, and tug/barge joined.

For further information and a free brochure, Circle 45 on Reader Service Card REEL-O-MATIC Reel-O-Matic Systems Inc., of Wrightsville, Pa., offers a variety of machinery to the marine industry.

One of the most popular pieces of equipment is the series CPD or custom power drum. This unit is constructed of a fabricated steel drum mounted in bearings with various drive styles available. These machines are built to customer requirements for size and capacity.

The CPD is designed primarily for storage and winching of cables and lines in marine usage.

A special weather-proofing package for shipboard environment is also available. This package includes stainless steel shafting, totally enclosed motors and controls, sealed bearings, and galvanized undercoating with rubberized paint.

These same corrosion-preventive measures can be applied to any of Reel-O-Matic's equipment that have applications throughout the marine industry.

Another frequently used piece of equipment is the RS/VS series of shafted stationary coiling and reeling machines. These units can be bolted or welded to the deck of a ship to pull any flexible material onto a reel or coil. The RS/VS is offered with various drive configurations to suit any particular need.

Reel-O-Matic's HJ/KVS series mobile reeling and coiling machine also is often used aboard ship because it has all of the outstanding features of the RS/VS and, in addition, it is mobile. A configuration of locking wheels and swivel casters allows this machine to be easily moved from job to job.

For further information, Circle 46 on Reader Service Card SCHOELLHORN-ALBRECHT The Schoellhorn-Albrecht Division of St. Louis Ship manufactures the 1824 family of deck capstans that have been in service for more than 40 years. These capstans have fully normalized and stress-relieved cast steel barrels and right-angle worm gear housing. They are driven t h r o u g h a s t r u c t u r a l - f r a m e - mounted, spur-gear-reduced, rightangled worm gear drive. The worm drive operates in a continuous oil bath, and the bronze bushings have pressurized grease fittings.

Primary power is provided by a 30-hp marine electric motor fitted with a 120-percent torque capacity magnetic disc brake.

The 1824 capstan is designed to provide 10,000 pounds of pull at 55 feet per minute, and 20,000 pounds at 28 fpm. Ultimate pull is 55,000 pounds, with an ultimate static holding capacity of 100,000 pounds.

Other deck capstans with barrels of 14 to 24 inches, driven electrically, pneumatically, or hydraulically, are available. Also featured in a new brochure available from Schoellhorn is a smaller, totally redesigned capstan/carpuller. These surfacemounted units, designed for less severe marine and industrial applications, are available with operating capacity from 5,000 to 15,000 pounds at 30/50 feet per minute.

For further information and a free copy of the brochure, Circle 47 on Reader Service Card SMATCO The SMATCO, Inc. Division of TBW Industries of Houma, La., supplied complete shipsets of Norwinch low-pressure hydraulic deck equipment for two anchor-handling/ tug/supply vessels built by Halter Marine for Penrod Drilling of Dallas. The two 225-foot, 12,280- bhp vessels are being used primarily for long-distance towing of semisubmersible rigs, and other towing and anchor-handling tasks.

The Kodiak I and Kodiak II are each equipped with one 4S-250-2T 250-ton waterfall hydraulic anchorhandling/ towing winch. This unit is powered by four Norwinch lowpressure hydraulic motors, and is arranged to enable either of the drums to provide full pulling power.

Both drums can provide half pulling power simultaneously, and they can be operated independently of each other in either direction of rotation.

This system gives the advantage of allowing a controlled maximum load on the lines, preset by the operator.

The winch is also equipped with a Norwinch high-power, hydraulic dynamic braking system, which provides control of speed and pull.

Also on board is a type S-50-1T 30-ton hydraulic anchor winch type bow windlass. This unit is powered by one Norwinch low-pressure hydraulic motor, and consists of a declutchable drum, a declutchable cable lifter for 38-mm chain, and two fixed warping heads. The vessels also have two hydraulic tugger winches, type MV-12. In addition, each vessel has two hydraulic capstans, type C-9.

For additional information, Circle 48 on Reader Service Card SMITH BERGER MARINE Smith Berger Marine Inc. of Seattle is well known for its line of durable marine fairleaders that are designed and built to withstand the rigors of the marine environment.

The line features heavy one-piece, machined steel sheaves that are mounted on heavy-duty bearings.

Smith Berger fairleaders are selfaligning and self-balancing, which provides positive seating when used in any line tension and with any lead direction.

The company's staff provides individual service and prides itself in providing deck machinery that meets any special requirements of each customer.

For additional information, Circle 49 on Reader Service Card STANSPEC The Stanspec Corporation of Cleveland, designers and manufacturers of materials-handling equipment, offers a line of standard and custom-built Rightway™ deck winches. These winches are manufactured to customer specifications from interchangeable, standard components. Capacities of the units range from 500 to 50,000 pounds, with electric air, gasoline, or hydraulic power available.

Among the standard features of the Stanspec winches are totally enclosed motors, safety brake, precision gearing, free-spooling drum, and an all-steel fabricated base. Optional features include an electric motor brake and a torque limiter switch.

For further information and free catalogs, Circle 50 on Reader Service Card SUPERIOR • LIDGERWOOD •MUNDY Lidgerwood Manufacturing Company of New York, was established in 1873 as a continuation of the Speedwell Iron Works of Morristown, N.J. From its standard hoisting equipment, Lidgerwood evolved marine winches.

These were produced extensively for steam power and later were adapted to electric applications.

Capstans, anchor windlasses, and marine winches still continue to be a source of pride to Lidgerwood, which has definitely stood the test of time.

The company offers a full range of well-illustrated literature that details the capabilities, special features, and specifications of its line of marine equipment. Included are marine equipment such as integrated barge moving systems; carpullers; capstans; steam hoists; trawling winches; towing winches; mooring bits and winches; cargo winches; gasoline, diesel, or electric hoists; anchor hoists; crane, dock, hatch cover, and dredge hoists, and windlasses.

For further information and free literature, Circle 51 on Reader Service Card TIMBERLAND Timberland Equipment Limited of Woodstock, Ontario, now offers a Canadian-built choice in mooring and anchoring systems with a wide range of winches that will handle up to 2'/z-inch wire rope.

Timberland has designed and manufactured powered winches for more than 25 years for the construction, mining, and marine industries.

Recently they have expanded the product line to serve a wider range of winch applications for mooring, anchoring, and positioning of service vessels.

For additional information, Circle 52 on Reader Service Card UNIT CRANE Unit Crane & Shovel Corporation of New Berlin, Wise., manufactures a series of hydraulic Unit Mariner pedestal-mounted marine cranes that meet 1983 American Petroleum Institute specifications covering offshore cranes.

The latest Mariner line offers lift capacities of 27,000, 36,000, and 55,000 pounds, with basic boom lengths at a 30-foot radius. Modular assembly is said to provide fast assembly and easily accessible servicing.

A variety of hydraulic winches is available to meet specific load capacities and line speed requirements.

An exclusive Power Demand hydraulic system, powered by diesel or electric prime movers, automatically matches hydraulic working pressures and horsepower to load requirements. Deck configurations include remote or onboard power, walk-around control, or fully enclosed cab.

For further information and free literature, C i r c l e 5 3 o n Reader S e r v i c e Card WASHINGTON CHAIN A new machine from Washington Chain & Supply Inc. of Seattle offers an easy, hydraulically powered method for wire rope socketing.

Marketed under the name Cab-LMate, the machine provides a oneman process for positioning wire rope into a socket.

The machine is offered in two versions.

Model 101 accommodates wire rope up to 2 inches thick and operates with dies in Vi -inch increments.

The larger model 201 handles wire rope from 2 to 4 Vi inches; dies for the 201 are made to special order only. Both machines are hydraulically operated with manual control valves.

For additional information, C i r c l e 5 4 o n Reader S e r v i c e Card WASHINGTON CRANES Washington Cranes of Seattle, a division of Ederer, Inc., offers a new generation of revolving cranes said to have increased reliability, lower maintenance, and more efficient operation due to the greatest possible capacity for a given size.

Typical of the line is the 150-ton revolver installed at Todd's Seattle yard. Advanced design concepts incorporated in that crane include Ederer dc adjustable voltage controls for all motions, all-electric operation, and a high-efficiency operator's cab. The crane has all independent hoists, each with its own solidstate control.

All gearing is in totally enclosed oil baths, and all hoist machinery is gear-driven. These new cranes have unique travel trucks, with each drive motor driving one wheel. This design allows increased load on existing tracks. The diesel generator house is located over the portal to isolate noise, lower the center of gravity, and improve accessibility.

The main hook lifting capacity of the Todd crane is 150 tons at a 55- foot radius, and 50 tons at 120 feet.

The auxiliary hook lifts 15 tons at all radii from 61 to 210 feet. Main hook speed is 12 feet per minute, auxiliary is 100 fpm. The boom can be fully elevated from the fully lowered position in three minutes. Power is supplied by an onboard 685- bhp diesel generator set.

For more information, C i r c l e 5 5 o n Reader S e r v i c e Card WILDEN PUMP Wilden Pump & Engineering Company of Colton, Calif., manufactures an air-operated, positive displacement pump designed to handle very thick and very abrasive materials. The heart of the pump is its unique air valve that shifts the air supply to both diaphragms alternately with complete reliability under all conditions of head and flow.

With no electrical connections, the pump is abrasion resistant, selfpriming, submersible, and has variable volume/pressure and simple clamp band construction.

Up to 90 percent solids and more than 250-foot heads are no problem for the Wilden pump, as the double diaphragm design cuts velocity in the unit to half total discharge velocity. The most abrasive slurries are handled with ease, as there are no seals and no metal-to-metal contact.

Volume is infinitely variable by controlling the air flow to the pump, from a few gallons per minute to more than 14,000 gallons per hour.

No pressure relief valve is required, and the pump can run dry indefinitely without damage.

Wilden pumps are available with wetted parts in aluminum, cast iron, stainless steel, and Hastelloy C; non-wetted parts are aluminum or cast iron. Elastomers are neoprene, Buna N, Nordel, Viton, or Teflon.

For further information on Wilden pumps, C i r c l e 5 6 o n Reader S e r v i c e Card

Read DECK MACHINERY/ CARGO HANDLING EQUIPMENT in Pdf, Flash or Html5 edition of October 1984 Maritime Reporter

Other stories from October 1984 issue

Content

- McDermott Scotland Gets $ 8 5 + Million Order For Offshore Jacket & Modules page: 4

- TECO Transport Signs Export Coal Contract With Freeman United page: 5

- AAPA Moves Headquarters To Arlington, Virginia page: 6

- Unique Conversion Job Completed By LEEVAC page: 6

- Keel Laid At Jeffboat Yard For Paddlewheeler 'General Jackson' page: 6

- Bender Monitors Protect Offshore Power Supplies page: 6

- Hyundai Delivers First Ship Built In Korea For Australian Owner page: 6

- Seaward Supplies 53 Fenders For Conoco's Hutton TLP page: 7

- Cantrill Appointed Vice President of Sales For Lister Diesel Inc. page: 7

- Helton Appointed Vice President Of Sea-Land Alaska Division—Other Promotions Announced page: 7

- Shaver Re-Engines Tug Columbia With Stork-Werkspoor Diesels page: 8

- First Of Ten Sister Log Carriers Delivered By Mitsui's Tamano Yard page: 8

- Cape-Bay Shipbuilders Offer Free Literature On "American Tug-Yacht 38' page: 8

- Capital Marine Uses Computer Technology To Streamline Business page: 8

- Lykes Orders Two More Containerships In Japan At Cost Of $76 Million page: 9

- First Mitsui/Hatlapa Ram Type Steering Gear Completed page: 9

- KaMeWa Reports Lively Interest In Water Jet Propulsion Units page: 9

- Hirt Named West Gulf Operations Manager For Ryan-Walsh Stevedoring page: 9

- International Ship Structure Symposium '84 page: 10

- St. Augustine Trawlers Awarded Contract To Build Cat-Powered Vessel page: 11

- Most Powerful Heavy Lift Cargo Ship Delivered by Hitachi Zosen page: 11

- Brown & Root Announces Corporate Reorganization page: 13

- Hunter Sheridan Named President Of Global Marine Development Inc. page: 14

- Alfa-Laval Promotes Spitzer To Division VP page: 14

- United Technologies Names Skiba Operations Director For Diesel Systems Unit page: 14

- Literature Available On Harbormaster Transverse Mounted Propulsion Unit page: 14

- MMS (UK) Ltd. Appoints John Gregory As Managing Director page: 15

- Furuno Introduces New Digiscan Radars page: 16

- Rolls-Royce Gets Contract For Gas Turbines To Power Dutch Frigates page: 16

- Hyde Awarded Contracts For Deck Machinery On Korean-Built Vessels page: 16

- Scientific-Atlanta Gets $8.5-Million Contract For Shipboard Platform Work page: 16

- New Literature Describes Neese Protective Clothing page: 16

- FISH EXPO '84 page: 18

- GASTECH '84 page: 18

- PAMS Installs New Drydock At Its River Plant page: 22

- Kidde Offers Free Brochure On Marine Fire Protection page: 22

- Miller Named Deputy Director-Marine Engineering At M. Rosenblatt & Son page: 26

- New Bulletin On Baskets And Screens Available From Hayward page: 26

- Jordan Lieb Joins Marine Coatings As Vice President page: 26

- Falk Granted Exclusive US Sales And Manufacturing Rights For Renk Drives page: 26

- Sternwheeler 'Music City Queen7 Delivered By Marine Builders page: 26

- 70-Page Color Brochure And Orderbook Chart Available From Samsung page: 26

- DECK MACHINERY/ CARGO HANDLING EQUIPMENT page: 28

- Furuno Appoints New Direct Sales Force page: 28

- Hitachi Completes Crude/Products Carrier For Arapaho Shipping page: 28

- Crude/Chemical/Products Tanker Delivered By Wartsila's Turku Yard page: 30

- Big Ship Radar Line Introduced By Furuno page: 30

- EXPOSHIP Far East 84 page: 32

- Literature Available On Supercompact Radar From Furuno page: 35

- New Brochure Describes Heat Exchanger Designs page: 35

- Etheridge, Mangum And Brightwell Join SOFEC In Houston Office page: 35

- Halifax Shipyard Gets Contract For C$10.7 Million To Modernize Canadian Coast Guard Tender page: 39

- Pientka And Brooks Named Vice Presidents At Comstat TeleSystems page: 39

- Newport News Shipbuilding Readies Roosevelt For Launch page: 39

- Multipurpose Vessel xHoegh Dyke' Delivered By Wartsila's Turku Yard page: 40

- Hugh Morgan Elected Vice Chairman And A Director Of Sonat Inc. page: 40

- ASMAR Completes Repairs To Chilean-Owned Frieghter page: 45

- Articulated Loading Platform Now Operating At Mobil's Statfjord XXC" Site page: 46

- Wartsila To Build 2,500-Passenger Ferry For Rederi AB Slite page: 46

- Mitsui Completes Big Products Tanker For Olympos Trading Corporation page: 47

- Steven Wolgamot Named Executive VP Of Two Operating Companies page: 49

- First Sulzer RTA84 Engine Successfully Started page: 49

- LEEVAC Announces Three Personnel Appointments page: 49

- MarAd Seeking RO/ROs For Ready Reserve Force Fleet page: 50

- MARCO Seattle Delivers The xNene' —Second Vessel For Hawaiian Islands page: 51

- Harbormaster Offers Free 8-Page Brochure On Propulsion Units page: 51

- Marine Section Of NSC Sets Annual Convention Oct. 15-17 In Chicago page: 52

- Henschel Promotes John Carter To VP-Advanced Programs page: 54

- Kori Will Continue Building Amphibious Vehicles At Port Of Iberia Site page: 56

- Defnet Named Marketing Vice President For Manitowoc Engineering page: 56

- Computer Helps With Cargo Load Monitoring And Business Management page: 57

- Eastern Marine Yard Launches Ferryboat For Lake Champlain page: 60

- Waukesha And Guascor Enter Agreement For New Diesel Series page: 62

- Unidynamics/St. Louis Offers 24-Page Brochure page: 62

- Shipbuilding Standards Committee Of ASTM To Meet December 12-14 page: 63

- Bethlehem Licenses DLI For Vibration Measurement And Analysis System page: 66