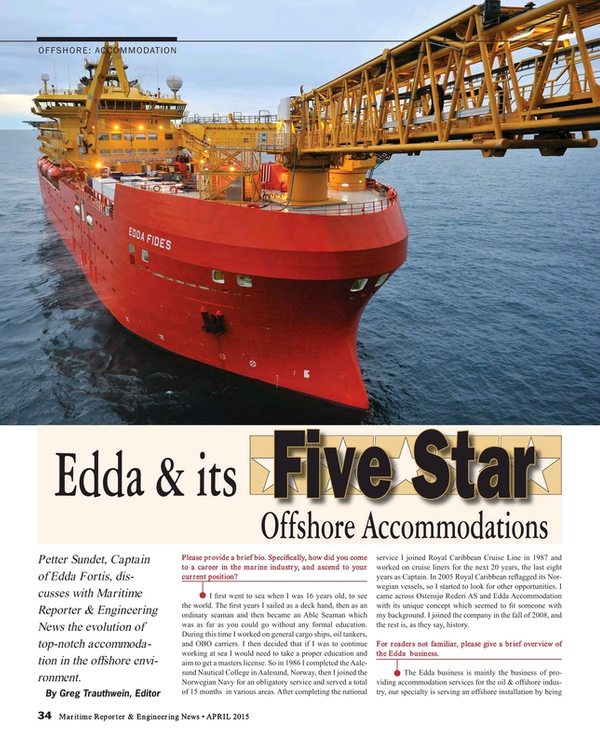

Edda & its Five Star Offshore Accommodations

Petter Sundet, Captain of Edda Fortis, discusses with Maritime Reporter & Engineering News the evolution of top-notch accommodation in the offshore environment.

Please provide a brief bio. Specifically, how did you come to a career in the marine industry, and ascend to your current position?

I first went to sea when I was 16 years old, to see the world. The first years I sailed as a deck hand, then as an ordinary seaman and then became an Able Seaman which was as far as you could go without any formal education. During this time I worked on general cargo ships, oil tankers, and OBO carriers. I then decided that if I was to continue working at sea I would need to take a proper education and aim to get a masters license. So in 1986 I completed the Aalesund Nautical College in Aalesund, Norway, then I joined the Norwegian Navy for an obligatory service and served a total of 15 months in various areas. After completing the national service I joined Royal Caribbean Cruise Line in 1987 and worked on cruise liners for the next 20 years, the last eight years as Captain. In 2005 Royal Caribbean reflagged its Norwegian vessels, so I started to look for other opportunities. I came across Østensjø Rederi AS and Edda Accommodation with its unique concept which seemed to fit someone with my background. I joined the company in the fall of 2008, and the rest is, as they say, history.

For readers not familiar, please give a brief overview of the Edda business.

The Edda business is mainly the business of providing accommodation services for the oil & offshore industry, our specialty is serving an offshore installation by being positioned close to such an installation with the help of dynamic positioning. The vessel can off course also be used as an accommodation unit for any sore side project where the vessel would simply stay moored alongside a pier.

In the move toward “Accommodation Vessels” for use in the offshore market: What has been the driver?

The driver for this trend was the increased need for flexible solutions in serving offshore installations with accommodation units, i.e. accommodation units that could mobilize and demobilize in a short time and that could move from one area of the world to a different area without the need for tugboats and with a speed similar to that of a regular vessel.

What is the EDDA solution in this regard, giving specs on both vessels working and under construction?

Our solution to this issue is to use a vessel where we focused on the possibility of using a mono hull type vessel with a telescopic gangway off the bow of the vessel and where the vessels position is controlled by dynamic positioning.

In building these vessels, what was the greatest challenge to design, construction and outfitting?

The greatest challenges to the design, outfitting, and construction of the vessel was to create a stable platform for the offshore gangway and the construction of the gangway in itself. For example the vessel is equipped with an advanced anti roll system consisting of U-shaped tanks with blowers to move the water from side to side, this has shown promising results in model tests and we have great expectations to the system. The rest of the vessel is built to known standards and class notations as follows: DNV, +1A1, SF, E0, DYNPOS AUTRO, CLEAN DESIGN, NAUT-OSV(A), ICE-1C, DK (+), Fire Fighter II, COMF-C(1), COMF-V(1), Passenger Ship. HELDK-SH, CRANE(N)

Recruitment & Retention in the maritime and offshore markets is a recurring theme in markets good and bad. Give some insight, from the EDDA perspective, as to how these specific vessels can offer a competitive advantage to those that employ them?

We believe that these vessels are attractive for both potential clients and anyone working on them since they are a unique combination of a working vessel and a passenger ship, so especially for sailors this gives a challenge that is not often found in the maritime world, and also for potential clients because they get a working vessel that gives them the amenities of a passenger ship in terms of accommodation quality. Usually these kinds of projects has been solved by the use of accommodation barges that has quite basic quality on the accommodation, we on the other hand offer the quality of a nice hotel which we think is what is needed to get more efficiency out of the work force. Another of the great advantages with our vessels is that we can easily connect and disconnect the gangway from an offshore installation and this is especially of importance in areas where weather conditions may change rapidly such as the cyclone season in Australian waters and the hurricane season in the Gulf of Mexico.

In overview, what do you count as the biggest challenge to running an efficient, profitable operation today?

This should be answered by people with a higher level of intelligence and knowledge than me, however it seems to me that one challenge that the shipping industry has always had is the over optimistic belief in the market at times when the brakes should/could have been put on. I believe history has shown numerous times that ship owners have ordered way too many ships and because of that having to put vessels in lay up as seen recently with the container companies and the offshore companies. At this time, several new accommodation vessels and units are under construction and will be entering the market in a time where we see a slow market and naturally the oil majors will push the daily rates towards the low end. Also it is important to control the spending, this is something for the economists to explain but I guess there should be a certain balance between what you potentially can earn and what expenses you can have.

We often write regarding emerging regulation and its impact on ship owners. Looking at the broad legislative landscape, what do you see that you think will have the biggest impact on your bottom line in the coming years? How are you preparing now to dull that impact?

When it comes to emerging regulations I would like to say that our company has great experience in dealing with different rules and regulations since we operate in very different environments and has had to adapt to different sets of regulations all the time, i.e. we have operated in the North Sea (British Sector), the Mediterranean, Bass Strait Australia, and the Gulf of Mexico all of which have very different national regulations, as well as working for different clients that very often also has different requirements. I believe this is the daily life of almost every shipping company today.

Looking at the market you serve, give a short “market update” on the conditions you see now.

The present market is slow due to falling oil prices as oil majors seems to cancel or postpone their planned projects which were based on high oil prices. As for us (Edda Accommodation) we are committed for both Edda Fjord and Edda Fides until approximately Q2 2016. The Edda Fortis remains open, however we can see a couple of projects that are suitable for our high end vessels and the impression is that charterers appreciate our accommodation service including the flexibility of the vessels, gangway solutions, highly skilled crew and focus on HSE & Q.

This may be repetitive from the previous, but how is the low price of oil impacting your company today?

One should think that a low oil price was good for anyone operating ships since we are high users of oil, however it may not be so for the offshore business since the oil price is important for the level of the activity in the search for oil and all activities connected to that. Since we operate in the oil service business we are off course subject to these conditions and less activity means less available projects and more competition for the few projects that materializes.

Looking at the markets you serve, by niche or by world region, where do you see opportunities for EDDA in the coming 12 months, and why?

I do not have hands on information on this, however it is my understanding that the most likely opportunities in the next 12 months are in the Gulf of Mexico, West Africa, and Australia

The Edda Fleet

Edda Fjord

Length, o.a. 104m

Breadth 22m

Draft max. 8.2m

Propulsion 2 x Diesel electric CP propellers

Thrusters 2 x tunnel thrusters

forward (1200kW each) +

1 x Azimuth thruster (1500kW).

2 x tunnel thrusters aft (1000kW each).

Max speed 16 knots

Berths 210

Built 2002

Shipyard Flekkefjord Slipp og Maskinfabrikk, Flekkefjord Norway

Edda Fides

Length, o.a. 130m

Breadth 27m

Draft max. 7.2m

Propulsion 5 x Voith Schneider

32R5 EC/265-2 x 2500 kW

Thrusters 2 x Brunvoll tunnel

thrusters x 1400 kW

Max speed 11 knots

Berths 600

Gangway 50m telescopic heave compensated offshore gangway

Built 2011

Shipyard Astilleros HJ Barreras,

Vigo Spain

Edda Fortis

Length, o.a. 154.9m

Breadth 32.2m

Draft max. 8.2m

Propulsion 6 x Schottel Azimuth thrusters (3 x 4050kW fwd.,

3 x 4050kW aft).

Max speed 13 knots (design)

Berths 800

Gangway 57m telescopic heave

compensated offshore gangway

with adjustable pedestal

Built 2015

Shipyard Hyundai Heavy Industries, Ulsan Korea

(As published in the April 2015 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)

Read Edda & its Five Star Offshore Accommodations in Pdf, Flash or Html5 edition of April 2015 Maritime Reporter

Other stories from April 2015 issue

Content

- They said it ... page: 13

- Risk & Reputation in the age of Disruption page: 14

- Underway on LNG page: 18

- ReFRESCO-Operation Unique Opportunities in CFD page: 22

- Dispersants ... Will we ever be able to use them again? page: 24

- Logistics and Warehouse Insurance: Understanding its Complexity page: 28

- Simulation & Ice Navigation Training page: 32

- Edda & its Five Star Offshore Accommodations page: 34

- Talking Offshore Employment with Faststream’s Chief Executive page: 40

- Oil Majors Push Offshore Players for 30% Cuts page: 44

- Harkand Haldane DP3 Dive Support Vessel: A New Wave of DSV page: 63

- Five Minutes with Halul Offshore CEO, Vivek Seth page: 66

- OSV Technology: Notable Designs & Deliveries page: 70

- VT Halter Powers Ahead page: 74

- The German Shipbuilding Rebound page: 78

- Alfred Hartmann: New Captain on the Bridge at VDR page: 82

- Boatbuilding in China page: 90

- E-Procurement Streamlined via the Cloud page: 93

- Ballast Water Technology Installation & Innovative Drive Contols page: 96

- Sludge Management System page: 98

- New Water Maker page: 98

- GEA UV Ballast Water Treatment page: 98

- Ecochlor BWTS page: 98

- ABB's New Azipod Thruster page: 99

- SENER Debuts Latest FORAN Release page: 99

- ExxonMobil Debuts Premium AFME 200 page: 99

- Hospital Ship Up to Speed with AMOS page: 99

- BV Upgrades RAM Software page: 99

- Tank Coating for Navig8 Chem Carriers page: 100

- VGP-compliant Frease from Klüber Lubrication page: 100

- Barkeeper: Centrifugal Separation Module page: 100

- SeaHow Skimmer System page: 100

- Roxtec Seals for Floating Tidal Turbine page: 100

- Beier Radio Celebrates 70th Anniversary page: 105