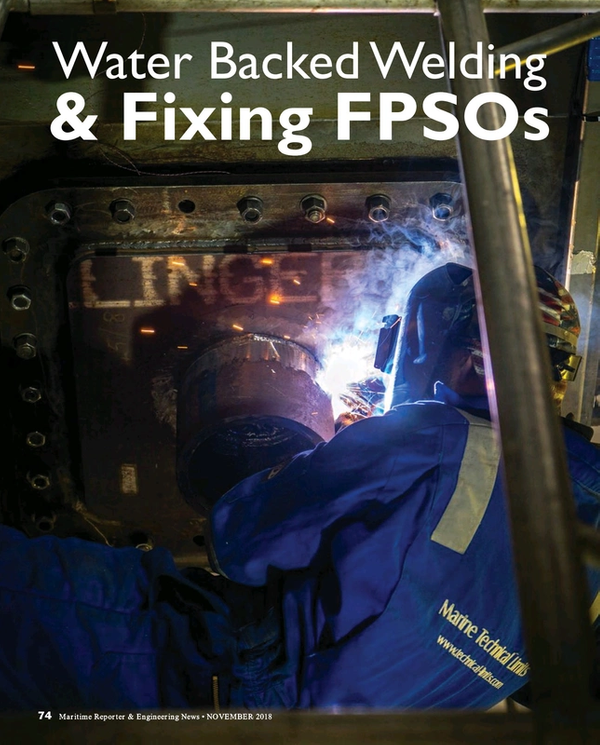

Water Backed Welding & Fixing FPSOs

Although MTL has a robust oil and gas heritage, with formidable experience in the global energy marketplace, it also invests heavily in R&D and undertake rigorous testing and research from its base in Kintore, Aberdeenshire. MTL recognizes the importance of progression and continual improvement for the benefit of the organisation and its staff. As a young engineer I’ve been afforded the opportunity to see new ways of working develop from the spark of a good idea through rigorous testing and finally to its successful deployment in the field. The freedom to explore fresh ideas is a compelling opportunity for any ambitious technician.

Innovation does not happen in isolation and MTL works closely with clients to quickly come up with bespoke solutions to unique problems.

FPSO Maintenance

FPSOs have played a key role in extreme offshore areas for many years, and an FPSO system is one of the most commercially viable concepts for remote or deep-water oilfield developments.

Harsh offshore environments, vessel motions and production demands can put FPSOs under stress. Ineffective inspection and maintenance regimes not only negatively impact the safety of the asset but can introduce onerous and unnecessary costs.

As an FPSO ages, an increasing number of defects can develop in the hull structure and problem areas found below the waterline can be particularly challenging to address. As dry docking may not always be a financially viable option for making repairs below the waterline, alternative methods are sought.

MTL identified that welding afloat with a water backing, or water backed welding, could be a solution. As it is not a commonly used or well-established welding process, there is limited Classification Society code guidance on whether it could be a viable option. But at MTL we empower our team to tackle these challenges, develop ground breaking concepts, appraise them through rigorous trials and testing, and ultimately deliver them to the market.

In light of this, we have recently undertaken extensive research and in-house welding trials to better understand water backed welding and its associated challenges.

Water backed welding creates more demanding conditions compared to conventional welding processes. At the same temperature, the water acts as a greater heat sink than air, which significantly increases the cooling rate of the weld. This rapid cooling results in a harder, more brittle weld that is not considered compliant with welding rules and standards. Therefore, it is not possible to achieve a suitable weld without altering the welding process or introducing preheat, a process which is against some Classification Society rules during water backed weld procedure qualification.

A thorough examination of the welding process and the specific alterations required was needed to render this technique feasible. Trials were undertaken using a bespoke welding test tank connected to an industrial water chiller unit, allowing the simulation of the conditions and flow rates found offshore. Water temperatures below 0°C were used to simulate the lowest temperature that could be encountered offshore during a repair. Throughout these trials, welding variables such as the welding process, position, technique, consumable and steel composition, as well as environmental conditions, were all examined to understand what impact they would have on weld quality.

By completing a full and thorough schedule of non-destructive and mechanical testing on each weld, MTL was able to obtain an understanding of the variables which affect the weld quality during water backed welding. MTL also identified the specific environmental control measures required to produce an acceptable water backed weld. By fine tuning the process and the introduction of specific controls for several variables, MTL was able to conduct successful welding trials which passed all non-destructive and mechanical testing requirements. MTL achieved this without the introduction of preheat and therefore avoiding additional challenges to the process. With the knowledge gained through MTL’s extensive water backed welding trials, MTL also requalified some of its conventional weld procedures to align its welding consumables and processes, with all preparation and welding being undertaken in-house at its premises in Kintore, Aberdeenshire. The qualifications covered both full penetration butt welds and fillet welds in a range of positions, again without the use of preheat. These were witnessed and approved in accordance with an internationally recognized welding standard, and in compliance with several Classification Society rules. By completing the research and trials in-house, MTL was able to gain a wealth of specialist knowledge of water backed welding along with a clear understanding of a range of welding codes. In the pursuit of excellence and continual development, this allows MTL to ensure all of its procedures are tailored specifically to customer’s project requirements as well as MTL’s core business areas.

Read Water Backed Welding & Fixing FPSOs in Pdf, Flash or Html5 edition of November 2018 Maritime Reporter

Other stories from November 2018 issue

Content

- The Forward-Facing Coast Guard page: 10

- U.S. Flag Vessel Safety page: 12

- Preventing Maritime Vessel Explosions – The Role of the Marine Chemist page: 16

- Software Solutions: Communicate or Stagnate page: 20

- Joey Farrell: Born to Marine Salvage page: 28

- Work‘bots’: Autonomous Vessels Arrive page: 34

- Shipyards: FMG & its Quest to Build USCG Icebreakers page: 44

- Interview: Admiral Karl Schultz, Commandant, United States Coast Guard page: 46

- Interview: Shuichi Iwanami, Commandant, Japan Coast Guard page: 54

- AET Grows in Brazil page: 60

- Shipyard Report: Abeking & Rasmussen page: 66

- Shipyard Report: Detyens Shipyards page: 70

- Water Backed Welding & Fixing FPSOs page: 74