Software Solutions: Communicate or Stagnate

It’s likely that you are reading this article in your office. And for most of us, that means a large, open-plan space arranged with desks, monitors, break-out rooms and other features designed both to keep us productive and to facilitate communication and collaboration. We have New York City to thank for the emergence of the shared office back at the turn of the last century. But it is relatively recently that “Bürolandschaft”, or office landscaping, became popular encouraging workers to sit more organically based around flows of communication.

Ask any office planner – or corporate boss for that matter – why they favor open-plan over separate cubicles or offices. Increased collaboration is likely to top the list. When people share the same space, they are more likely to share ideas and ask for input. Even with today’s social media dominance, people are social beings at heart and want to interact in-person. Data has to flow through a company, and sharing the space facilitates that. Open-plan is also, of course, much cheaper both in terms of construction cost and because more employees can occupy less square meters, but it also delivers flexibility. We might not know what the next office trend will be, but a large shared-space doesn’t close down the options.

Building efficiencies

In many aspects of our family, social and workaday lives, we have in-built efficiencies. Open-plan offices is just one example; so is the fact that we use our smartphones to connect to the world wide web and a variety of social sharing platforms; and that our laptop applications all interconnect to allow data, images and other information to be shared seamlessly and without fuss.

The question is, therefore, if this is part and parcel of our normal lives, why are most shipping companies woefully under-integrated?

Most shipping companies will say that they have fully embraced the digital revolution, and that’s largely true. Almost all will be using an accounting package to manage invoicing, budgeting and bill paying. For some, this will be a simple Excel spreadsheet, but for most it is likely to be a more sophisticated made-to-measure package. Most will also be running software packages to administer a range of other commercial and operational functions. But the issue is one of integration. While these individual packages perform a discrete set of tasks perfectly well, they don’t communicate with one another.

Achieving integration

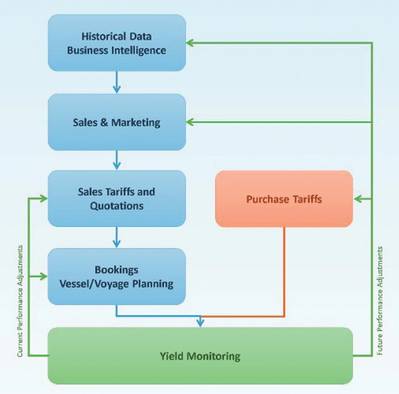

In a fully integrated shipping company, the tariff system captures all the complex information relating to individual customers, ports, terminals and cargoes – and this can be a hugely complicated matrix of individual prices, restrictions, discounts and incentives. When a customer requests a quotation, the quotation system should automatically look up the relevant tariff to create a bespoke and accurate quotation.

If the quotation turns into a sale, the system will, again, automatically create the required booking confirmation, bills of lading, manifest and more.

And once the vessel has sailed, an invoice will be automatically generated and that information will be posted to “accounts receivables” via an interface.

During this process, if changes need to be made, a fully integrated system will automatically create manifest corrections, credit notes and invoices at the press of a button.

In other words, information will flow seamlessly from one activity to another without the need to re-enter data. Retyping leads to errors, errors lead to delays and delays disrupt cashflow and cost money.

Reducing the argument to a monetary basis, it is widely understood that around 10% of global outgoing freight invoices are incorrect due to human error in transferring information from one system to another. Even for a small shipping company boasting a modest revenue of $100 million, that means $10 million in dispute and not being paid – and a subsequent hole in the cash-flow.

Image: Softship

Image: Softship

Finding a solution

Evolution is probably the main culprit for the current state of affairs. Shipping companies have adopted digitization piecemeal and so have installed individual packages to perform specific tasks as required, or as budget became available. The resulting mix of sometimes bespoke and sometimes off-the-shelf packages has generated a maze of applications that sit alongside each other, but which don’t integrate or communicate. A huge amount of data is re-keyed between disconnected departments within the same shipping company.

To scrap what is already in place and start afresh is a daunting and time-consuming task. Many shipping companies are simply not prepared to take two steps backwards in order to make three or more in the right direction. Coupled with this, most IT departments are struggling to remain compliant with an ever-increasing raft of external reporting regulations which are required just to keep the company trading. Internal integration will always play second fiddle.

But there is a solution. Modern shipping software is modular, meaning shipping companies need only select the applications they require to automate certain processes within their businesses. Each module seamlessly integrates with others to facilitate a flow of information across the company.

Data need only be input once, thus reducing duplication, errors and silo working. Data is then shared across the company and with relevant business partners. This significantly reduces the administrative burden and introduces efficiencies across the business. It also frees up staff to focus on more customer-oriented tasks.

A well-thought-out software application will retrieve variable costs per shipment from a cost database and apply these as estimated costs to the booking. Information on volumes taken from the customer at the time of booking are automatically married with this data to provide analysis and profitability assessments for each consignment.

And, as the voyage progresses and actual costs become known, real-time updates allow profitability to be monitored throughout the voyage. Automating these processes enables a valuable amount of data to be captured, shared and reused throughout the company. It can also be analysed for performance reporting encouraging management to make smart and informed decisions.

More so, good shipping-oriented software will also manage and monitor voyage progress and port call activities. Schedules can be monitored and updated from arrival, departure and noon-reports automatically received from the vessel. Changes caused by unforeseen events can be simulated to provide estimates of the potential impact on the overall schedule. The operator can then simulate the “what ifs” and find the most appropriate countermeasures.

But while there is a good solution to achieve full integration within shipping companies, resistance remains.

Overcoming resistance

Twenty or more years ago, digitization was the prerogative of the very large shipping company with deep pockets. They developed bespoke applications and recruited armies of technicians to look after them. But times have moved on and, today, it is a fairly simple process to buy specialist solutions that can be easily configured and customized to suit the individualities of each company and user. These packages are the means to make digitized companies into digitally-integrated companies.

The beauty of these applications is that they are built to facilitate total integration between each of the core processes – connecting existing systems through a single over-arching, fully connected and seamlessly networked entity. So, data flows seamlessly between ship operations, commercial, container logistics, accounting and management.

Other than the obvious advantages of less data input, reduced errors and the ability to deliver heightened customer service, these packaged solutions are available at a fraction of the price of building a bespoke system. Effectively, they have leveled the IT playing field across the entire spectrum of shipping companies.

Like the open-plan office, or the smartphone, or the laptop, many shipping companies are beginning to raise their heads from the day-to-day to see the advantages of having their various business functions communicate with each other. Like all good ideas, the concept is very simple, and with packaged software now widely available, achieving full integration is easily within reach.

The Author

Lars Fischer is the Managing Director of the Asia Pacific headquarters of Softship. He is responsible for Singapore’s commercial and technical staff of 25 and for the group’s sales & marketing strategy worldwide. www.softship.com Lars Fischer

Lars Fischer

Read Software Solutions: Communicate or Stagnate in Pdf, Flash or Html5 edition of November 2018 Maritime Reporter

Other stories from November 2018 issue

Content

- The Forward-Facing Coast Guard page: 10

- U.S. Flag Vessel Safety page: 12

- Preventing Maritime Vessel Explosions – The Role of the Marine Chemist page: 16

- Software Solutions: Communicate or Stagnate page: 20

- Joey Farrell: Born to Marine Salvage page: 28

- Work‘bots’: Autonomous Vessels Arrive page: 34

- Shipyards: FMG & its Quest to Build USCG Icebreakers page: 44

- Interview: Admiral Karl Schultz, Commandant, United States Coast Guard page: 46

- Interview: Shuichi Iwanami, Commandant, Japan Coast Guard page: 54

- AET Grows in Brazil page: 60

- Shipyard Report: Abeking & Rasmussen page: 66

- Shipyard Report: Detyens Shipyards page: 70

- Water Backed Welding & Fixing FPSOs page: 74