OSVs: Fishing for Value

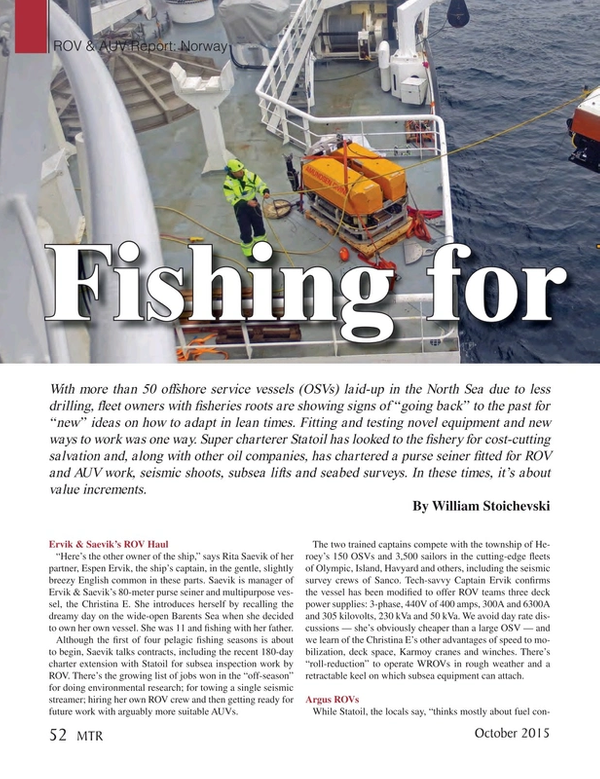

With more than 50 offshore service vessels (OSVs) laid-up in the North Sea due to less drilling, fleet owners with fisheries roots are showing signs of “going back” to the past for “new” ideas on how to adapt in lean times. Fitting and testing novel equipment and new ways to work was one way. Super charterer Statoil has looked to the fishery for cost-cutting salvation and, along with other oil companies, has chartered a purse seiner fitted for ROV and AUV work, seismic shoots, subsea lifts and seabed surveys. In these times, it’s about value increments.

Ervik & Saevik’s ROV Haul

“Here’s the other owner of the ship,” says Rita Saevik of her partner, Espen Ervik, the ship’s captain, in the gentle, slightly breezy English common in these parts. Saevik is manager of Ervik & Saevik’s 80-meter purse seiner and multipurpose vessel, the Christina E. She introduces herself by recalling the dreamy day on the wide-open Barents Sea when she decided to own her own vessel. She was 11 and fishing with her father.

Although the first of four pelagic fishing seasons is about to begin, Saevik talks contracts, including the recent 180-day charter extension with Statoil for subsea inspection work by ROV. There’s the growing list of jobs won in the “off-season” for doing environmental research; for towing a single seismic streamer; hiring her own ROV crew and then getting ready for future work with arguably more suitable AUVs.

The two trained captains compete with the township of Heroey’s 150 OSVs and 3,500 sailors in the cutting-edge fleets of Olympic, Island, Havyard and others, including the seismic survey crews of Sanco. Tech-savvy Captain Ervik confirms the vessel has been modified to offer ROV teams three deck power supplies: 3-phase, 440V of 400 amps, 300A and 6300A and 305 kilovolts, 230 kVa and 50 kVa. We avoid day rate discussions — she’s obviously cheaper than a large OSV — and we learn of the Christina E’s other advantages of speed to mobilization, deck space, Karmoy cranes and winches. There’s “roll-reduction” to operate WROVs in rough weather and a retractable keel on which subsea equipment can attach.

Argus ROVs

While Statoil, the locals say, “thinks mostly about fuel consumption.” Saevik says she would prefer they and other oil companies brought their own ROV’s aboard. Statoil and other oil companies have chartered the Christina E. for five assignments.

“I hired the personnel and the two ROVs,” she says, adding that the resulting earnings are “just not comparable” to profitable fishing. She confirms, though, that the local fishing vessels in the fleets of offshore vessel owners are growing despite shrinking fish quotas.

To serve crews, the ROV pilot room is has the feel of an high-end OSV. The Danish cook is more chef than cook. Saevik says she spent $700,000 on art.

We remove our shoes to follow a first officer tiptoeing to the engine room in her socks. ABB has tweaked the electrical and propulsion system so the 2.5MW and 4.5MW engines can handle a seismic operation’s heavy tow. “It’s EM seismic,” says Saevik.

“You’re towing a cable that pulses the ocean bottom.”

Several days later, we called Argus ROVs, who Saevik had hired for the Statoil gigs. A voice on the line told us their ROV operation aboard the Christina E “Went much quicker and smoother that on some other jobs. The crew were very efficient.” Class’s DNV GL has helped her get machinery and equipment ICE-C compliant for ROV surveys. It’s not known whether her HIPAP 500 hydro acoustic sonar was put to work for offshore work (it surveyed the bottom for the environmental surveys). There’s deck space for three 20-ft. ROV containers.

ORG Geophysical

SINTEF brought its own ROV when doing ocean research. Two other research institutes and the oil companies have also made use of the comfortable cabins for 34, the conference room, the three bridge work areas and separate Inmarsat data network. Summer 2015 saw the Christina E perform a 90-day seismic survey for ORG Geophysical in the Barents Sea. It followed a similar one in 2014. Environmental survey work on the British and Norwegian sides of the North Sea in 2013 rounded out a season that also saw an ROV LoVe installation and separate seabed survey. Two more ROV environmental surveys were won in 2012.

“The ship has been used for WROV, survey, installation of subsea equipment and seismic,” Saevik says, adding that “offshore support” and AUV operations are also suitable work (as is pipe and cable-lay inspection). In summer 2014, a 10-week AUV tender was won, but it was decided instead to follow the promise in a six-month seismic contract that came with options.

The Broker

The break from purse seining in order to do Statoil subsea work in September suggests Ervik & Saevik see the oil company as vital for their future. “The mackerel season can’t be interrupted,” says Saevik, so it was cut short, instead, for that 180-day contract and its options.

The cranes, space and crew are clearly adept at removing and adding equipment to match the job and season. Yet, while ROV and AUV crews have a willing, able and compliant charter vessel in the Christina E (she’s won an environmental award for her NOx), Saevik clearly sees the need to grow. The Christina E., it turns out, has “one competitor in southern Norway.”

“We dared to go offshore,” but then “The learning curve was through the roof,” Saevik says. It was fitting acknowledgment of Statoil’s rigorous supply chain qualification program. Meanwhile, Ervik and ABB’s reworking of the vessel to make the most of her DP 1 and CAT engines; her bottom-scanning sonar and winches has created a multi-purpose vessel, or MPV, and capable OSV for cost-conscious project managers.

“I want more vessels,” Saevik says. Yet, like the other OSV owners all she can do is “tell the brokers she’ll be free (for offshore assignments) soon.”

All charters go through them.

Sanco looks to GoM

Pulling a single streamer, long-line style, might soon be the work of many, judging by the dire seismic market sized up by Sanco chief operating officer, Rudy Amundsen.

A market economist, now, and a former Ramform captain, Amundsen remembers Sanco entered the seismic market on a fishing vessel converted to refuel OSVs and carry their equipment and parts. Today, like the original Sanko Chaser, the ice-class tanker Sanko Sky chases vessels that pull long nine-kilometer, 15-cable streamers. All seven Sanco vessels are built here in Sunnmore, including the 4D-capable Sanco Star (now with OceanGeo) and the Sanco Swift and Sanco Sword with Dolphin Geophysical offshore Australia.

Sanco is fresh from the record-setting 125--sq.-km. shoot offshore Myanmar for Shell Myanmar, where the Sanco Sword spread its 12 streamers to a “record” (per-kilometer) day rate and spread of 12 sq. km.

Now, with a 50 percent cut in seismic budgets being felt the world over, Sanco is looking to the past fisherman’s strategy of retooling. At Las Palmas in the Canary Islands — a base being revitalized by others, including Rolls-Royce — Sanco is fitting seabed seismic equipment but faces delays ahead of a planned shoot in January 2016 with Houston-based OceanGeo.

The Bad News

Exacerbating today’s dearth of surveys, there’s a persistent oversupply of vessels and fierce competition for the few going tenders. About 40 high-end, 3D seismic vessels will be out of work by year-end 2016, says Amundsen.

“The good-times contracts are expiring, and within the year for most,” he warns. In that time, there’ll be two massive PGS vessels delivered from Japan. “It’s just not a good market now,” and not helped, he says, by elections in formerly active Nigeria, where contract delays are now the norm, or sanctions that have hurt Russian exploration. Worse, a project of WesternGeco’s is understsood to have sailed from new-build quay to cold-stack. Polarcus, once a market darling, runs its own vessels but owes nearly USD800 million, although new September geophysics sales ought to help.

The Good News

Dolphin, now equipping its new-builds, plies Russia’s Kara Sea with Sanco, although U.S. companies are still active there, so sanctions have yet to fully disrupt global marine deal-making. The good news comes from Sanco client PGS and the chance several of its vessels will soon find employment off Newfoundland, Canada — toward which the Sanco Spirit was last known to be steaming — and on the Mexican side of the Gulf of Mexico. The final stages of pre-funding for multi-client promises an opportunity to sell results for a company with three cold-stacked Ramform survey vessels. “Fifty-percent prefunding is good enough for most,” says Amundsen on when a multi-client survey operations begin to look profitable.

In a note to shareholders PGS says things ought to start looking better for seismic in 2016.

DOF, Statoil ID ROV Value

As DOF Subsea — with its 71 OSVs and 11 ROV types — announces $350 million in Canadian, Australasian and Gulf of Mexico contracts for inspection, maintenance and repair, or IMR, it’s clear, here, that the mini submersibles from rival Bergen were key.

The IMR work is unavoidable for oil companies, and the DOF awards show the value of having several ROV and AUV types in your purpose-built fleet of subsea construction vessels. ROVs can keep you competitive when times are tough. Further up the littoral, in quietly busy Ulsteinvik, people remember when the ROVs of Island Offshore earned work inspecting moorings for a billion-kroner new-build still waiting for its first major Statoil offshore construction mission.

Unlike DOF’s success, the news here is modest at best — two more laid up vessels, this time for Havyard, but Statoil has just signed a deal with the simulator centers at Aalesund and Faasnavaag to train all future subsea crane operators and ROV pilots in integrated, “augmented” subsea operations. The simulator award may seem like mere necessity, but it belies another hidden market for ROVs: supporting subsea lifts and inadvertently jacking up the quality of subsea simulation training by feeding mission experience to designers of the SIM projector technology.

U.K. expat Joel Mills, the Aalesund-based technological design director behind the simulators of Faasnavaag Academy and the Centre of Excellence in Aalesund, says that both the electronic tags on the subsea equipment being installed and the new equipment aboard today’s ROVs “feed each” in a spatial, information loop.

The Aalesund facility’s dome crane simulator will train all involved in an entire subsea operation, while Faasnavaag will do individual training, including ROV SIM training from Q4 2015. It’s understood that half of all NOV and all TTS cranes have been SIM’ed for training. Now training for complex operations with low-speed ROVs will be possible to augment the survey work of faster ROVs.

Aasgard Catalyst

It was Statoil’s training gear-up for the launch to the sea bottom of a giant gas compression manifold for the Aasgard oilfield that started the “augmented subsea” training here. Two WROVs have been in the SIM for over a year, but putting cranes and ROVs together in the SIM is new.

“In subsea crane lift you need a subsea view, and this is a fed view from an ROV,” says Mills.

He says about 85 percent of offshore accidents are down to humans, so “this type of training presents a savings in risk”.

ROV views have helped with the giant screen SIMs of “virtual prototyping” (a la Aker Solutions), but they’re still new to integrated operations training, even for Statoil. “The survey screen (looped from or to an ROV) is no longer 2D,” explains Mills, adding, “When you turn on your (navigating) screen you’re able to get a full 3D view. It’s like turning the lights on underwater.”

In the augmented subsea SIM reality, all the information gathered by ROVs is put back into the SIM for third-person viewing or for the crane operator to see directly into a structure for added visual security or just an excellent image of the seabed.

Via transponders on the ROVs, mission info is run through the real SIM “so there isn’t just a SIM scenario”. ROV tech increasingly also allows feedback for better future ROV designs.

“They’re more instinctive than a crane and better with regard to humans in the (info) loop. Joysticks point the ROV to where you want to go,” says Mills.

Mills, meanwhile, is just back from demoing a SIM of divers integrated with ROVs and cranes. “It’s still in the demo stage,” he says.

(As published in the October 2015 edition of Marine Technology Reporter - http://www.marinetechnologynews.com/Magazine)

Read OSVs: Fishing for Value in Pdf, Flash or Html5 edition of October 2015 Marine Technology

Other stories from October 2015 issue

Content

- Rim-driven ROV Thruster page: 10

- New ROV System from VideoRay page: 12

- New Ships Join the US Research Fleet page: 14

- Project Mars: The future of Autonomy page: 24

- SUPR-REMUS: The Next Generation of Plankton Sampling page: 28

- The Voice: Frederic Terral, CEO & President, Brand Architecture Inc. page: 32

- Autonomy by (Software) Design page: 38

- Shipping’s Stake in an Ocean Clean-Up page: 42

- Deep Ocean Engineering page: 46

- OSVs: Fishing for Value page: 52

- EIVA Software for Shallow Water Surveys page: 62

- Compact Guide Wire Cutting Tool for ROVs page: 62

- Brazilian Order for Tritech’s Gemini page: 62

- Teledyne RD Instruments Updates ADCPs page: 62