ANNUAL GUIDE TO FUELS and LUBES

To obtain the necessary improvements that will ensure the commer cial success of the newest generation of high-output engines, additives must be used in lubricants.

And although the use of additives in internal combustion engine lubricating oils is nothing new, having begun over 70 years ago, recent advancements in organic chemistry have led to excellent results with new additives.

Some additives take the form of complex compounds of sulfur, phosphorus or a combination, or fall into a group called antioxidants. The use of various additives reduces organic acids, sludge and the breakdown of crankcase lubricating oil due to oxidation, carbon build-up, and component wear, all of which can hurt engine performance, increase the risk of mechanical failure and most importantly increase maintenance costs.

Besides newly developed additives for marine lubricants, other companies are offering special treatments for fuels which improve combustion, reduce deposits, or kill fuelcontaminating microbes.

The following article is based on the results of a brief survey of many of the leading suppliers of marine lubricants and fuel additives conducted by the editors of MARITIME REPORTER & ENGINEERING NEWS. Further information, including specification sheets, technical and literature, is available on any of the products reviewed in this article. To obtain free literature, circle the appropriate Reader Service Number on the post-paid Reader Service Card bound into the back of this issue.

CASTROL MARINE OILS The Castrol Company was a pioneer in the critical area of cylinder lubrication of slow-speed crosshead engines. Because uprated crosshead engines burn more fuel per cylinder unit volume and have a higher tendency to convert the fuel's sulfur into its acid component, Castrol engineers addressed the alkalinity of the cylinder oil as measured by Total Base Number (TBN).

Early in 1989, the company launched its unique Castrol Marine Cyltech 80. This highly successful crosshead engine cylinder oil has a TBN of 80 and contains a unique antiwear additive combination.

The owner can either use Cyltech 80 at the same feed rate as a conventional product and achieve savings through greatly reduced wear of components or he can reduce the feed rate of Cyltech 80 by at least 15 percent and achieve direct cost savings on his cylinder oil bill while still maintaining or improving the wear profile of cylinder liners and pistons.

According to Castrol, since it has been in use, Cyltech 80 has consistently exceeded the company's performance predictions. Castrol reports that cylinder liner wear can be reduced by up to 60 percent and piston ring wear by almost 50 percent.

In an effort to maintain a leading position in the marine lubrication technology field, Castrol has extended its R&D program to investigate the effects on lubrication of high surface temperatures on cylinder liners and piston rings.

For further information on Castrol marine lubricants, Circle 54 on Reader Service Card CHEVRON USA Chevron USA markets a variety of premium lubricants for marine applications in the United States including: Chevron Marine Engine Oils Delo 477 (SAE 20W-40)—recommended for use in main power, medium-speed two- and four-cycle diesel engines such as those used in towboats, tugs, workboats and dredges; Chevron Delo Heavy Duty Motor Oils (SAE 10W, 20,30,40, 50)— recommended for supercharged marine diesel engines; meets the requirements of the great majority of high-speed diesel engine manufacturers, both domestic and international; Chevron Marine Engine Oils Delo 1000,2000,3000 Marine (SAE 30 and 40)—recommended for a wide variety of medium-speed trunk piston engines including the latest design high output engines; Chevron Delo 100 Motor Oils (SAE 10W, 20, 30, 40, 50)—recommended for use in two- and fourstroke cycle diesel and four-stroke cycle gasoline engines; Chevron Delo 300 Motor Oils (SAE 10W, 30, 40, 15W-40)—recommended for all heavy-duty and supercharged engines; Chevron RPM Heavy Duty Motor Oils (SAE 10W, 30, 40, 50, 10W-30, 15W-40)—recommended for all heavy-duty and supercharged engines; And Chevron Marine Engine Oil Symbol 9250 (SAE 40) can be used in any engine where U.S. mil spec MILL- 9000H Symbol 9250 oil is required.

In addition to these products, Chevron USA produces a variety of lubricants and greases for marine applications.

For more information on Chevron marine lubricants and their specific applications, Circle 50 on Reader Service Card DREW AMEROID To minimize fuel costs, many operators are purchasing bunker fuels which meet the lowest possible specifications recommended by the engine manufacturers. This initial cost savings can be offset by handling and combustion-related problems due to the fuel's poor quality.

Drew Ameroid® Marine, a division of Ashland Chemical, Inc., and a leading supplier of chemical treatments to the marine industry, has recently developed three fuel treatments designed to minimize specific problems associated with the use of today's typical marine fuels: AmergyR 222 fuel oil conditioner, a premium blend of solvents, dispersants, surfactants, and detergents, is designed to minimize the effects of fuel instability and incompatibility; AmergyR 1000 combustion improver, a product containing no metal, is designed to promote the complete burning of hydrocarbons contained within fuel, ensuring the release of the maximum thermal energy possible during combustion; AmergizeR deposit modifier/combustion improver, contains ingredients which promote more complete combustion and also reduce deposits and corrosion in combustion spaces.

Drew's international network of service technicians provides added value to each chemical purchase through support programs. One such program is PACE™ fuel evaluation which provides comprehensive analyses of the chemical and physical properties of bunker fuels, with follow-up recommendations to ship operators.

For free literature detailing Drew Ameroid Marine's fuel treatment products, Circle 27 on Reader Service Card EXXON Exxon Company, U.S.A., markets several lines of quality marine lubricants.

Exxon's marine lubricant line includes De-Mar 17, an LMOA Generation 5 heavy duty crankcase lubricant for both main and auxiliary diesel engines. Zinc-free, highdetergent De-Mar 17 has a 17 TBN and is non-corrosive to silver bearings.

It is accepted by all the major marine engine manufacturers and has been proven in Caterpillar 3601 and Detroit Diesel 6V92T engine dynamometer tests.

The latest Exxon generation of marine diesel lubricants, the Exxmar line, exceeds the performance requirements of low- and medium-speed diesel engines under todays conditions and has more than an adequate margin for future needs over the next several years, according to Exxon.

Combined with excellent wear performance, its standards of cleanliness are high with good overall control of deposits, even when operating on higher viscosity lower-grade residual fuels. Lower TBN Exxmar products are specifically meant for use in earlier model diesel engines.

The high load carrying capacity of the Alkaline crosshead system oil is also been proven as an asset for the more demanding power take-off (PTO) gear application.

Other marine lubricants offered by Exxon include: Spartan EP, a non-lead, extreme-pressure lubricant for enclosed gears and bearings operated under heavy load or shock load conditions; Spartan Synthetic EP, a high VI long-life extreme- pressure gear and bearing lubricant; Nuto H, an anti-wear hydraulic oil; 1209 Turbine Oil, a rust and oxidation inhibited antiwear marine turbine oil, MIL-L- 17331-H approved; and Univis N, a line of high viscosity index antiwear hydraulic oils.

For free literature detailing the Exxmar line of marine lubricants from Exxon, Circle 53 on Reader Service Card FERROUS Ferrous Corporation, Bellevue, Wash., offers both fuel and lubricant additives for the marine market formulated to improve combustion or reduce corrosive wear. The additives include: Gear-Saver lubricant additive improves the lubricating oil's viscosity index greatly reducing heat's harmful effects, and adds film strength for better lubricant surface retention. Ferrous reports that Gear-Saver extends the life of gear box and other lubricating systems through better cold start lubrication, reduced friction, lower operating temperatures and improved break-free surface lubrication throughout the system.

Sea-L-Saver lubricant additive is a premium quality lubricant that blends with all petroleum-based oils and fluids, improving efficiency and extending their operating life. It also extends the life of seals in stern tubes, bow thrusters and hydraulic systems.

Fuel-Guard microbiocide is blend of highly active antimicrobial compounds for the treatment of stored fuels. Readily soluble in all grades of fuel oil, Fuel-Guard is effective in reducing bacteria, fungi, and yeasts found in contaminated fuels.

BT-8 fuel stabilizer and sludge dispersant is formulated to improved the stability and burnablity of fuels by reducing the formation of residues and sludges. BT-8 is nonmetallic and completely ashless.

MP-4 combustion catalyst and ash modifier promotes rapid oxidation of fuels for more efficient combustion, and maintain exhaust valves and superheater tubes free of vanadium and sulfate deposits. Its is readily soluble in all grades of fuel oil and is intended for use in diesel engines and boilers.

For further information on Ferrous Corporation fuel and lubricant additives, Circle 49 on Reader Service Card HAMMONDS BioborR JF is a concentrated liquid fuel additive from Hammonds Fuel Additives, Inc., used to eliminate Hydrocarbon Utilizing Microorganisms (HUM) or HUM-Bugs, in all hydrocarbon fuels such as aviation jet fuel, kerosene, No. 1 and 2 diesel fuels, home heating oil, marine diesel and bunker C fuels.

Hammond claims that when used on a regular basis, Biobor JF, known as a microbiocide, will maintain fuel quality by not allowing microorganisms to grow.

"These HUM-Bugs are only microscopic in size, but they're causing serious harm," says Walter Chatrand, director of marketing for Hammonds Fuel Additives, Inc.

Even though there are more than 250 types of bacteria and fungi that can live in the water bottom of fuel tanks, only fewer than a dozen actually feed on the fuel and produce acid waste byproducts.

If left untreated, the small percentage of HUM-Bugs can damage diesel-powered ship fuel systems by clogging filters and lines. At the same time, the acid content of their waste byproducts corrodes fuel tanks, pipes, distorts, rubber hoses and seals, and increases wear on equipment by adding deposits to various engine components.

In various case studies, according to Hammonds, the small cost of using Biobor JF far outweighs the cost of repairing engines or related parts damage. At a recommended maintenance dosage of approximately one-half gallon of Biobor JF for every 5,000 gallon of fuel, the expense of using a biocide costs only half a cent for every gallon of fuel treated.

For free literature detailing Biobor JF from Hammonds, Circle 28 on Reader Service Card MOBIL OIL Recent developments in crosshead engines have targeted increased power and fuel efficiency to reduce operating costs. This has resulted in higher temperatures and pressures in the cylinder, which reduce the lubricant's viscosity and increase the loads which it must withstand. Longer piston strokes have greatly increased the amount of surface to be protected and the amount of time the lubricant must withstand the severe cylinder temperatures and corrosive sulfur acids.

New Mobilgard 570 provides excellent protection through optimum viscosity at the higher operating temperatures and pressures of these modern engines. It employs new additives with substantially greater thermal stability and through new base oil refining technology, an optimum viscosity of 21 est at 100 degrees C is attained for best lubricant distribution and film retention.

In order to retain additive effectiveness at the higher temperatures of today's cylinders, Mobil chemists developed new, more thermally stable additives.

Other Mobil products include the more recently introduced Mobilgard 24 and 42 Series Oils for lubricating medium-speed trunk-piston marine diesels.

These new oils, said to offer longer engine life as measured by time before or between overhauls (TBO), are formulated to overcome a specific, persistent problem with heavy fuel-burning medium-speed marine diesels: contamination of lubricating oil by residual fuel. This usually occurs through inefficient injector operation, fuel pump leakage into the crankcase, or poor combustion.

The new Mobilgard 24 and 42 Series Oils are formulated to reduce the effects of fuel contamination.

This results in improved crankshaft and camshaft cleanliness; reduced piston and piston ring deposits, improved piston cleanliness, and longer filter life. Purifier deposits are also reduced. These oils also offer better thermal stability, resistance to oxidation and overall engine cleanliness, compared with some other oils.

The Mobilgard 24 Series includes grade 30 and 40 oils with a TBN of 30. The Mobilgard 42 Series, also available in SAE 30 and 40 weights, have a TBN of 40. The higher TBN Mobilgard 42 Series is intended to provide additional alkalinity reserve for engines with low oil consumption or low temperature cylinder liners, or which operate on higher sulfur fuel.

For free literature detailing Mobil lubricant products Circle 51 on Reader Service Card PRE-LUBE 6 Distributed by horizon Distribution and manufactured by Grignard Company, Inc., Pre-Lube 6™ is a polymer-based rust preventative and lubricant.

Pre-Lube 6 contains a patented rust-inhibiting polymer that bonds with metal, plastic, or vinyl surfaces when applied, creating a seal and protecting the surface from corrosion or rust.

Some of Pre-Lube 6's industrial users are U.S Steel, Bethlehem Steel, Conoco and Texaco. Military users include the U.S. Navy and Coast Guard. MIT, Woods Hole Oceanographic Institute, Bedford Institute of Oceanography, Columbia University, and University of Miami are among the research and educational institutions that use Pre-Lube 6 to protect their marine equipment.

In the marine environment, Pre- Lube 6 protects navigation lights, all engine parts, bw rails, fishing tackle, electronics, and even rub rails and plastic fenders.

For all moving parts, such as winches, fishing reels, steering cable, pulleys and bearings, Pre-Lube 6 provides protection and excellent lubrication.

Pre-Lube 6 was originally invented to protect U.S. Navy aircraft carrier deck pennants and purchase cables from rust.

For further details about Pre- Lube 6, Circle 55 on Reader Service C a r d SHELL CaprinusR U Oil 40 is Shell's premium quality single grade diesel engine oil recommended for use in modern medium-speed diesel engines in marine and stationary power applications.

Zinc-free Caprinus U Oil 40 is an LMOA Generation 5 performance oil and is approved by General Electric as a Generation 4 Long Life Oil and classified in the "Extensive Use" category by EMD of General Motors.

It is also recommended for GE ALCO Power and Fairbanks Morse engines. In marine applications, Caprinus U Oil 40 can be used in both main propulsion engines and many auxiliaries. Caprinus U Oil 40 prevent formation of hard carbon in ring belt areas and minimizes port blocking in two-stroke cycle diesel engines.

Premium multigrade oils maintain a tough film between moving parts, even at higher temperatures.

Caprinus Multigrades are formulated with ShellvisR, a patented viscosity index improver. Caprinus Multigrade Oils are available at two additive treatment levels: Shell Caprinus U 20W-40 at 13 TBN and Shell Caprinus UE 20W-40 at 17 TBN. Both SAE 20W-40 oils provide the unique performance benefits over an SAE 40 of reduced engine fuel consumption, reduced oil consumption and, in severe applications, longer oil drain periods through control of used oil viscosity increase.

Shelltrans™ Oils are blended in high-quality Shell MVT base stocks and are based on all the widely used additive treatments. Shelltrans Oils, with less than 10 parts per million of zinc and a viscosity index of 80, are approved for commercial use by EMD and GE and are recommended for use in many other medium-speed engines.

For free literature detailing the complete line of commercial marine lubricants available from Shell, Circle 52 on Reader Service Card TEXACO Texaco offers a complete line of quality marine lubricants which are available worldwide to meet the needs of all types of marine equipment.

For crosshead engines, Texaco offers Taro Special, a premium quality cylinder lubricant for large, slowspeed diesel burning residual fuels.

It is blended from highly refined paraffinic base oils and oil soluble additives to produce a high alkaline reserve (70 TBN) product with good lubricant film strength.

Taro Special EX 85 is a premium quality cylinder lubricant specifically developed to meet the requirements of Sulzer RLB engines. It is approved by Sulzer for those applications where an 85 TBN product with a viscosity of 24 est at 100 degrees C is specified.

Doro AR 30 (SAE 30) is a premium crankcase lubricant for large, slow-speed engines. It is blended from highly refined solvent neutral oils and carefully selected additives to produce a moderate alkaline reserve (6 TBN) oil. Doro AR 30 meets the Sulzer requirement for engines equipped with PTO units.

Texaco offers a complete line of trunk piston engine oils for mediumand high-speed diesels. The specific lubricant required would be based on sulfur content of the fuel being used in the engine. Taro XD oils, with a TBN of 15 minimum, are used in engines burning fuel with a sulfur content up to 1.8 percent. Taro XD and Taro DP are available in SAE 30 and SAE 40 viscosity grades.

Taro XL 40 (SAE 40) is for use in medium-speed engines where the operating conditions or fuel sulfur content requires a 40 TBN product.

Texaco supports its marine lubricants with prompt, efficient technical service and the Texlube used oil analysis program for monitoring the condition of oils in use.

For free literature detailing Texaco marine lubricants, Circle 56 on Reader Service Card

Read ANNUAL GUIDE TO FUELS and LUBES in Pdf, Flash or Html5 edition of July 1992 Maritime Reporter

Other stories from July 1992 issue

Content

- Markey Machinery Supplies Hawser Winch For LOOP Emergency Response Vessel page: 9

- Siemens Division Supplies Integrated Electric Propulsion System For B.C. Ferry page: 9

- $75 Million Cable Ship Launched By AT&T/ Teleglobe At FELS page: 10

- U.S. Owners Could Place $5 Billion In New Ship Orders page: 11

- Stolt-Nielsen Adds Two Inland Tankers; Acquires Comex Services page: 12

- New Oceanographic Ship Christened By MSC At Avondale page: 13

- Shaver Awards Z-Drive Tug Contract To Martinac page: 13

- Atlantic Marine Delivers 1,200-Passenger 'Empress/ New Illinois Casino Boat page: 14

- U.S.-FLAG CRUISING: READY TO SAIL? page: 16

- Unitor Offers Shipowners CFC 'Phase-Out7 Concept page: 19

- DIESEL POWER page: 21

- Great Lakes Towing Overhauls Army Tug, Expands Yard Facilities page: 28

- FMC Seeks Comments On Exempting Military Rates From ' 8 4 Ship Act page: 29

- Lugger Diesels Give Passenger Boats Economical High Speed page: 32

- CG Says New Regulations Will Remove Substandard Tankers And Operators page: 32

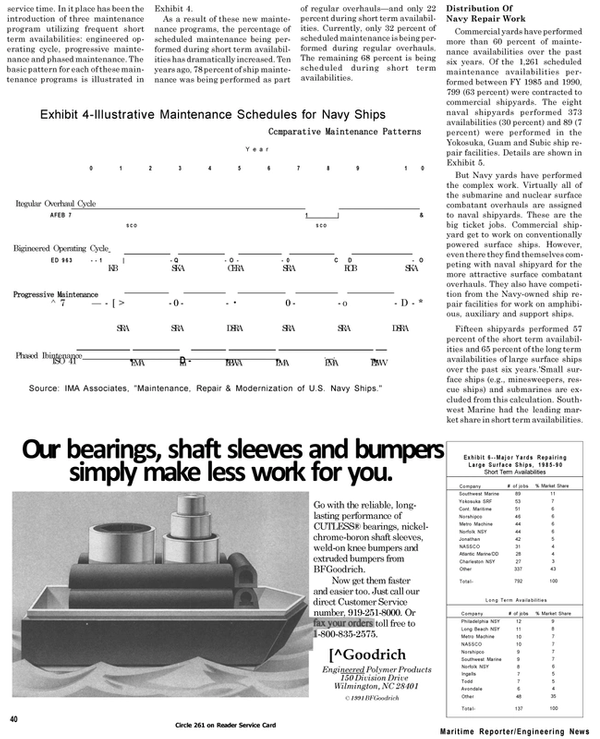

- Future Repair & Modernization Of U.S. Navy Ships page: 33

- Distribution Of Navy Repair Work page: 34

- ECO Delivers Two PC Ship Simulators To Navy page: 36

- Eighth LSD Class Ship Commissioned At Avondale page: 37

- ANNUAL GUIDE TO FUELS and LUBES page: 38

- COMSAT Introduces C-Linksm Dial-In Service page: 46

- NOR-FISHING '92 page: 48

- Soaring Shipbuilding Demand To Challenge Shipyard Capacity page: 49

- CREDIT IN THE BUNKER BUSINESS Pitfalls, Problems, Techniques And Solutions page: 52

- Singapore's Marine Industry Posts $ 1 . 9 Billion Growth page: 52

- Singapore Buys $12 Million VTS From Norcontrol page: 54

- FMC Issues Notice For 3 Proposed Rule Changes page: 54

- Fire Safety Actuators From N e w Joint Venture/ Stockham-Ficotech page: 55

- Siemens Launches New Industrial Systems Division page: 55

- Singmarine Launches One Of WorlcTs Largest Well Stimulation Vessels For The Western Company page: 55

- Mar Ad's Management Control Over Title XI Vessels page: 56

- HEIDRUN —A Breakthrough For Concrete Technology page: 58

- AWSC Helps 2nd-Tier Shipyards Comply With U.S. Disabilities Act page: 60

- PPM Cranes To Produce First U.S.-Built Container Reach Stacker page: 60

- SECONDHAND SHIPS: Market Sector Prospects And Investment Options During The 1990s page: 61

- Ashtech Ranger Receiver: Compact GPS Solution page: 62

- HMS Marine Introduces Halon Containment Curtain page: 62

- North Sea To Black Sea Waterway Set To Open page: 63

- New Marine Turbine For Fast Ferries From Solar Turbines page: 64

- Edson Offers Free Diaphragm Pump Catalog page: 64

- Leevac To Build Casino Boat To Rodney E. Lay Design page: 65

- Finnyards Receives 2nd $130 Million Multipurpose Icebreaker Order page: 65

- Futuristic Radisson Diamond: 21st Century Cruise Ship Delivered By Finnyards page: 66

- Flender Werft Delivers 1,724-TEU Boxship page: 67

- Lakes Shipping Affected By Low Water Levels page: 67

- MarAd Publishes Final Rule On Regulated Transactions page: 68