Ergonomics@Sea

Ergonomics is the science of designing for the human body. The goal of ergonomic design is to allow interfaces to easily connect with a human. Ergonomic design is not only easier and more comfortable to use but reduces injuries and accidents. Marine applications need special care because of vessel movement, unique hazards, multicultural crew and the extreme human machine interface environment where small controls operating enormous machinery.

The concepts behind ergonomics are rooted in a variety of disciplines such as human dimensions (anthropometry), human movement (kinesiology), user psychology and interaction design. While other elements of human comfort will not be discussed here, these include environmental issues such temperature, humidity, draftiness, air quality, noise and vibration.

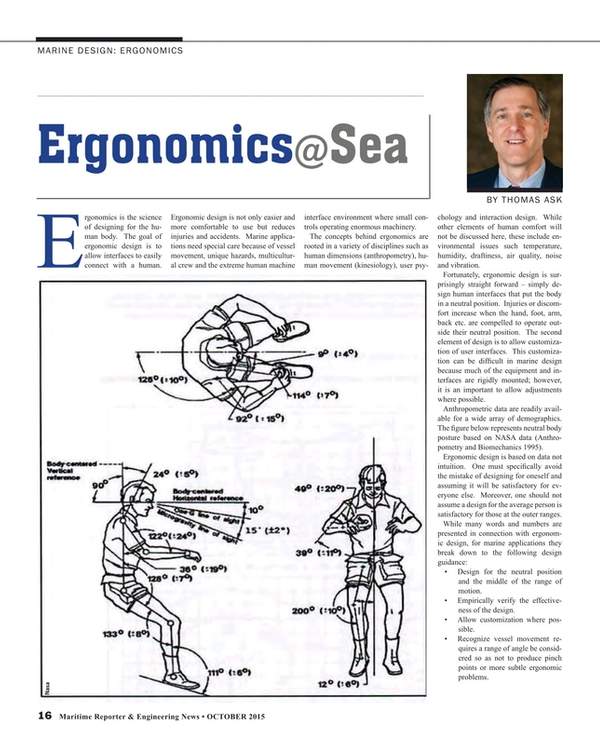

Fortunately, ergonomic design is surprisingly straight forward – simply design human interfaces that put the body in a neutral position. Injuries or discomfort increase when the hand, foot, arm, back etc. are compelled to operate outside their neutral position. The second element of design is to allow customization of user interfaces. This customization can be difficult in marine design because much of the equipment and interfaces are rigidly mounted; however, it is an important to allow adjustments where possible.

Anthropometric data are readily available for a wide array of demographics. The figure below represents neutral body posture based on NASA data (Anthropometry and Biomechanics 1995).

Ergonomic design is based on data not intuition. One must specifically avoid the mistake of designing for oneself and assuming it will be satisfactory for everyone else. Moreover, one should not assume a design for the average person is satisfactory for those at the outer ranges.

While many words and numbers are presented in connection with ergonomic design, for marine applications they break down to the following design guidance:

• Design for the neutral position and the middle of the range of motion.

• Empirically verify the effectiveness of the design.

• Allow customization where possible.

• Recognize vessel movement requires a range of angle be considered so as not to produce pinch points or more subtle ergonomic problems.

Many rules of thumb (heuristics) have been developed that guide designers, ranging from cockpit sight lines, extension to dexterity relationships and handle design.

Some correction factors that are helpful when dealing with raw anthropomorphic data include adding five percent to values to account for light clothing.

People can stretch 10 percent further than anthropometric data suggests by twisting their torso and extending their reach.

Mapping is another important interaction design concept. Mapping describes the relationship between visual cues and function, such as scissor handle movement mirroring the cutting blade action or Z-drive controller orientation indicating thrust direction. In products and systems that are vital to safety, it is critical to make the mapping as clear as possible and work with graphical language suitable for international crews.

When designs are changed, traditional mapping needs to be taken into account so that a new design is approachable by those who have experience with an old design.

Affordances and constraints should also be introduced to design to accommodate or constrain how a device is used. An example of this is scissor handle holes that are sized to handle either the fingers or thumb.

More extensive ergonomic design guidance includes:

• Work should be done by larges appropriate muscle groups.

• Avoid overexertion of connective tissues (muscles, tendons, tendon sheaths) in wrist.

• Avoid compression of the median nerve in the wrist’s carpal tunnel and use a natural grasp angle of 60-70 degrees, limit movement to 15 degrees.

• When lifting is required avoid wrist pronation (palm down) and supination (palm up) when lifting. Also ensure that the upper arms can be close to body and elbows operating around 90-100 degrees.

Ergonomic design is straightforward and most people have an intuitive sense for what works and what is comfortable. However, primitive function often drives designs and the process of making them ergonomic can be viewed as a second phase of the design process. The health and safety of crew can be improved by moving ergonomics to the early stage of marine design.

The Author

Thomas Ask is a professor of industrial and human factors design at the Pennsylvania College of Technology (USA). Ask earned a doctorate in industrial design and is a licensed Professional Engineer.

(As published in the October 2015 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)

Read Ergonomics@Sea in Pdf, Flash or Html5 edition of October 2015 Maritime Reporter

Other stories from October 2015 issue

Content

- Making Sense and Taking Risks: Human Behavior in the Shipping Industry page: 14

- Ergonomics@Sea page: 16

- The Cost-conscious Manager page: 20

- Black Market Refrigerants Pose Risk to Shippers page: 22

- Marine Firefighting at Sea: Training to Survive page: 28

- Unmanned Vessels: The Future is Now page: 34

- Foreship: New CFD Methodology page: 48

- SCANIA Expands its Engine Range for Marine Applications page: 50

- Towboat Honors Structural Engineer Dobson page: 54

- Ulstein’s X-BOW Turns 10 page: 55

- KVH Debuts mini-VSAT Broadband 2.0 page: 56

- BMT Fluid Mechanics to Validate FLNG Design page: 60

- Hard Problems Demand Soft(ware) Solutions page: 62