EUROPEAN SHIPBUILDING AND REPAIR

Spurred by a number of key factors— the replacement of older vessels in the world fleet, the cruise ship boom, impending double-hull and double-bottom legislation, and prospects of increased trade after 1992—the world shipbuilding orderbook reached a five-year high at the end of 1989.

With shipowners scrambling to find berths, European shipyards are acquiring a growing percentage of the workload.

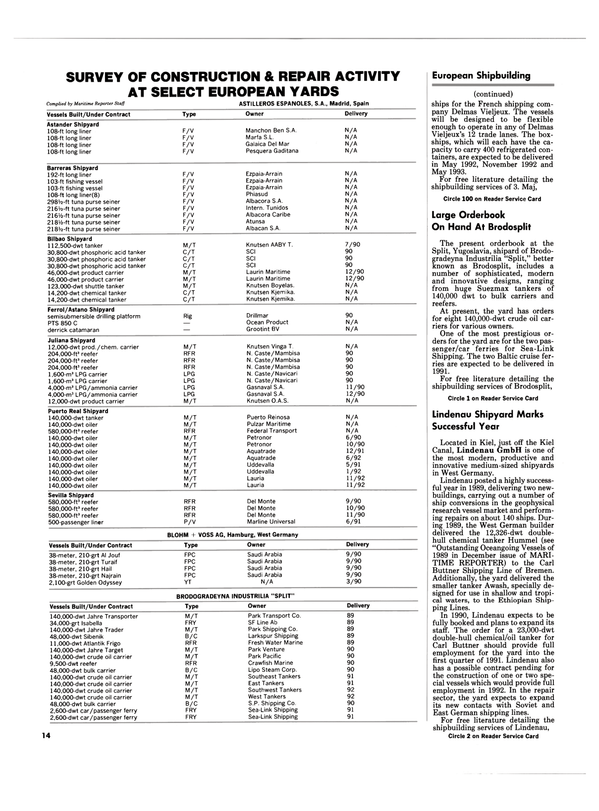

The following is a brief overview based on responses received as of press time of some of the principal European yards involved in shipbuilding, repair and conversion.

Portugal's LISNAVE Earns $130 Million During 1989 Frederico Spranger, commercial director of Portugal's Lisnave, reportedly the world's busiest shiprepairer, believes that there should be greater control over shipowners who neglect essential ship repairs.

"This will happen in Europe," said Mr. Spranger, "and it will be of long-term benefit to the ship-repair industry." In 1989, Lisnave earned about $130 million in the shiprepair sector.

During 1989, some of the major repair activity at Lisnave's North Yard at Rocha included structural repairs of the 14,867-dwt general cargo vessel Symphonic, operated by East Gulf Management, which involved more than 85 tons of steel work; alongside repairs on the U.S.

Navy helicopter carriers Nassau and Shreveport; and substantial repairs to the 8,636-dwt reefer Provincia De Los Rios, which included double bottom plating work, renewal of insulation and work on the MAN B&W main engine.

At Lisnave's South Yard at Margueira, the 280,428-dwt tanker Mobil Petrel, owned by Mobil Shipping Co., was drydocked for painting and inspection and steel repairs in her damaged tanks. Chevron Transport's M/T Chevron Horizon of 123,969 dwt, underwent normal blasting and painting and extensive renewal of damaged plating on her bottom and stern area. Machinery overhaul of three cargo and three stripping ballast pumps and retubing of her auxiliary boiler was also completed within a 67-day period.

P&O's deluxe liner Dawn Princess underwent refurbishment at the South Yard. Work included renewal of both her tailshafts and refit of new stern tube glands.

For literature describing LISNAVE's ship-repair services, Circle 97 on Reader Service Card $270 Million In Orders For Five Tankers Won By Astilleros Espanoles Spain's Astilleros Espanoles S.A.

(AESA), has been awarded two contracts from separate entities worth about $270 million for the construction of five tankers.

The first order worth a total of just under $150 million for three one-million-barrel tankers to be built by AESA's Puerto Real yard in Cadiz, Spain, was confirmed by Uddevalla Shipping.

Two of the 143,000-dwt vessels will be delivered in June 1991 and March 1992, while the third—a resale from France's CNN/Worms— will be delivered in October 1990.

A second contract for two Suezmax crude oil carriers has been placed with the Puerto Real yard by Spain's state-owned Empresa National Elcano.

Together, the ships are believed to be costing around $120 million.

Delivery of the 140,000-dwt vessels will be at the end of 1992 and beginning of 1993.

Astano shipyard, El Ferrol (La Coruna), Spain, recently endlaunched the semisubmersible drilling rig Drillmar I into Ferrol Bay.

The launching was unusual in that the unit was structurally complete with each lower hull resting on a separate slipway. The launching weight of 10,728 long tons included approximately 9,300 tons of steel and 1,400 tons of equipment. There remains approximately 2,600 tons of outfitting to be done at dockside before the unit is delivered to Drillmar in the second half of 1990.

The 270-foot-long by 203-footwide Drillmar I is a Friede & Goldman, Ltd.-designed Enhanced Pacesetter Semisubmersible. The twinhull six-caisson semi is capable of drilling to 25,000 feet as a thrusterassisted moored unit in water depths up to 1,500 feet.

The launching also marked the first entry for the Astano shipyard into the offshore market. Previously noted for its ability to produce supertankers, the Drillmar I represents Astano's changing emphasis away from ship construction and into offshore production. It also was the first time Astano had launched any structure from its two parallel slipways simultaneously. Careful calculations and model testing along with a strong lower hull design helped ensure the successful launch with a minimum (less than 2 tons) of structural reinforcement in the lower hulls.

For free color literature detailing the shipbuilding and ship-repairing services of the shipyards of AESA, Circle 98 on Reader Service Card Fincantieri Prepares P&O's Crown Princess For Delivery In Italy, the Monfalcone shipyard of Fincantieri Cantieri Navali Italiani is preparing to deliver the new 70,000-grt giant luxury liner Crown Princess to Princess Cruises, an associate of P&O Cruises Ltd.

The Italian-flag passenger ship recently completed her preliminary sea trials in the Adriatic Sea. The 1,748-passenger Crown Princess is fitted with a diesel-electric propulsion plant, which will feature four 14,400-bhp MAN B&W Diesel eight-cylinder L58/64 mediumspeed engines driving a pair of propulsion motors.

Fincantieri also is constructing a sister ship to the Crown Princess, the Regal Princess. She is expected to be launched shortly. Besides the two P&O cruise ships, the Italian shipbuilder also has contracts for two 1,600-passenger Costa Crociere liners and three 1,250-passenger Holland America Line cruise vessels.

Fincantieri's Ship Repairs Division, Genoa, has secured a contract from Italian owner NAVARMA to perform a major refit on a passenger/car ferry. The contract calls for the addition of hoistable and permanent car decks to increase car capacity; the extension of the after part of the existing superstruc- tures on the upper three decks; rebuilding of the accommodation area; and fitting of a new bulbous bow and new funnel.

After completion of the conversion by Fincantieri's OARN yard this spring, the Moby King (ex- Skane, formerly owned by the Swedish State Railway Company) will have a passenger capacity of 2,000 and car capacity of 700. She will enter service between the Italian mainland and Corsica in the summer of 1990.

Other work being undertaken by Fincantieri's Ship Repair Division in the passenger/car ferry sector includes the refit of a total of 10 vessels, four of the Poeti Class and six of the Strade Consolari Class.

For further information on Fincantieri, Circle 99 on Reader Service Card 3. Maj Awarded Contract To Build Three Boxships Rijeka, Yugoslavia-based 3. Maj S h i p b u i l d i n g was recently awarded a contract for the construction of three 2,200-TEU container ships for the French shipping company Delmas Vieljeux. The vessels will be designed to be flexible enough to operate in any of Delmas Vieljeux's 12 trade lanes. The boxships, which will each have the capacity to carry 400 refrigerated containers, are expected to be delivered in May 1992, November 1992 and May 1993.

For free literature detailing the shipbuilding services of 3. Maj, Circle 100 on Reader Service Card Large Orderbook On Hand At Brodosplit The present orderbook at the Split, Yugoslavia, shipard of Brodogradeyna Industrilia "Split," better known as Brodosplit, includes a number of sophisticated, modern and innovative designs, ranging from huge Suezmax tankers of 140,000 dwt to bulk carriers and reefers.

At present, the yard has orders for eight 140,000-dwt crude oil carriers for various owners.

One of the most prestigious orders for the yard are for the two passenger/ car ferries for Sea-Link Shipping. The two Baltic cruise ferries are expected to be delivered in 1991.

For free literature detailing the shipbuilding services of Brodosplit, Circle 1 on Reader Service Card Lindenau Shipyard Marks Successful Year Located in Kiel, just off the Kiel Canal, Lindenau GmbH is one of the most modern, productive and innovative medium-sized shipyards in West Germany.

Lindenau posted a highly successful year in 1989, delivering two newbuildings, carrying out a number of ship conversions in the geophysical research vessel market and performing repairs on about 140 ships. During 1989, the West German builder delivered the 12,326-dwt doublehull chemical tanker Hummel (see "Outstanding Oceangoing Vessels of 1989 in December issue of MARITIME REPORTER) to the Carl Buttner Shipping Line of Bremen.

Additionally, the yard delivered the smaller tanker Awash, specially designed for use in shallow and tropical waters, to the Ethiopian Shipping Lines.

In 1990, Lindenau expects to be fully booked and plans to expand its staff. The order for a 23,000-dwt double-hull chemical/oil tanker for Carl Buttner should provide full employment for the yard into the first quarter of 1991. Lindenau also has a possible contract pending for the construction of one or two special vessels which would provide full employment in 1992. In the repair sector, the yard expects to expand its new contacts with Soviet and East German shipping lines.

For free literature detailing the shipbuilding services of Lindenau, Circle 2 on Reader Service Card Lengthened Westerdam Delivered By Meyer Werft Meyer Werft of Papenburg, West Germany, redelivered the 798- foot, 53,872-grt luxury cruise ship Westerdam (ex-Homeric) to Holland America Lines, Seattle, Wash., after the vessel underwent an extensive conversion and lengthening.

The delivery of the Westerdam marked the successful completion of an e x t r a o r d i n a r y conversion.

Lengthened by over 130 feet, the vessel's passenger capacity increased by about 35 percent, from 1,332 to 1,773. The 669-foot-long Westerdam was first cut in two and her 7,000-ton forebody was moved on rollers almost 164 feet. Due to Meyer Werft's 600-ton-capacity crane available in its covered building dock, the 131.2-foot-long new midbody section was able to be fabricated in just a few pre-outfitted units.

A total of 195 new passenger cabins as well as 66 officers' cabins and 31 crew cabins were installed. Besides an increase in the number of passenger and crew cabins, public space was also considerably increased.

The existing restaurant on deck 4 now seats 868 passengers compared to 556 prior to lengthen- ing. On the Promenade Deck, a bar, card room, library, conference room and lounge were installed. Besides the extension of the pool area, the Sun Deck was equipped with two new whirlpools and a veranda restaurant.

The swimming pool can be roofed over by a magrodome.

General overhaul work was carried out on the propulsion machinery consisting of two 16,200-hp MAN B&W Diesel main engines, which transmit the power to two propellers, providing the ship with a speed of 21 knots. Upgrades were performed on the air conditioning, garbage-handling and alarm and monitoring systems.

Furthermore, the yard is preparing to lengthen the 5,723-m3 LPG carrier Sultan Mahmud Badaruddin 11 for Rupuk Sriwidjaja of Indonesia.

After conversion, the vessel, originally constructed by Meyer Werft, will have an overall length of 475 feet and a capacity of 8,700 m3. She will be delivered in July 1991.

For free literature detailing the facilities of Meyer Werft, C i r c l e 3 o n Reader Service Card Blohm + Voss Busy With Major Conversions Hamburg, West Germany-based Blohm + Voss, one of Europe's busiest ship-repair and conversion specialists, was recently awarded a $34.8-million contract to convert three paper carriers for Swedish owners Gorthon Lines.

The conversion of the three 14,299-ton bulk carriers into paper/ pulp carriers by Blohm + Voss will entail the removal of all her main deck equipment and the creation of a continuous weather deck. Additionally, a tweendeck will be added and access to both decks will be via two side-loading entrances.

Blohm + Voss also completed the $5.8-million conversion of Hapag- Lloyd's 37,012-grt cruise ship Europa late last year. The work involved upgrade and expansion of the onboard restaurant facilities.

The West German yard also recently completed the $9-million upgrade of the 10,600-ton ferry Bolerohas for Fred Olsen. The project called for the addition of 88 cabins (176 berths) and the overhaul of the vessel's doors, ramps and propulsion machinery.

For free literature describing the services of Blohm + Voss, C i r c l e 4 o n Reader Service Card Schichau Seebeckwerft Delivers Huge Railferry, Performs Conversions Bremerhaven's Schichau Seebeckwerft AG,a member of the Bremer Vulkan Group, recently completed what is reportedly the world's largest train ferry, the 622- foot Railship III, for the Railship Group (see cover story in this issue).

The 10,000-dwt railferry adds about 2,000 meters of rail length on three decks to the Railship Group's total.

The Group now operates three ships with a total of 5,600 meters of rail.

The ship, powered by a Wartsila Diesel propulsion plant, operates on the Travemunde to Hanko, Finland route.

Schichau Seebeckwerft, like other West German shipyards such as Lindenau, Meyer Werft and Blohm + Voss, has been very successful in obtaining complex conversion work.

One such project was the conversion of the former landing craft Jaeger in to a modern surimi factory processing ship for Oceantrawl of Homer, Alaska. Renamed the Northern Jaeger, the vessel has an overall length of 336 feet, breadth of 51 feet, depth to upper deck of 36 feet and draft of 19 feet. She is powered by two medium-speed Krupp MaK 8M453 C main engines, rated at 3,218 horsepower each, working via reduction gearing on a propeller arranged in a nozzle.

The Northern Jaeger now features accommodations in a threestory deckhouse located on the elongated fo'c'sle deck. A water treatment with a freshwater capacity of 400 tons per day was added, along with horizontal freezers and other equipment used in the processing of surimi.

For further information on Schichau Seebeckwerft, Circle 5 on Reader Service Card Wilton-Fijenoord Performs Ferry Repairs Strategically situated in the middle of the Rotterdam port area, the gateway to Europe, Dutch shiprepairer Wilton Fijenoord recently received contracts to repair the ferries Princesse Maria-Esmeralda and Reine Astrid, both operated in cross-Channel service by Regis des Transports Maritimes. The ferries Dorio Ferry, operated by P&O Steam Navigation, and St. Nicholas of the Sealink fleet are also in the Netherlands yard for repairs.

Some other vessels recently calling at the yard for repair work include the the 256,699-ton tanker Esso Languedoc, for alongside repairs, the Japanese refrigerated cargo vessel Kasuga Reefer for voyage repairs and the Paicific-Gulf Marine RO/RO vessel Nosac Ranger.

C.H. Stapel, deputy managing director of Wilton-Fijenoord, believes that current trends indicate that European shipyards will be among the leaders in the world shiprepair sector.

"On one hand," said Mr. Stapel, "the aging commercial fleet and the tendency to have older vessels in operation longer have no doubt had a spin-off (effect) to the yards, whereas on the other hand European yards are slowly catching up with those in the Far East in terms of price and turn-around times." For free literature describing Wilton- Fijenoord!s services, Circle 6 on Reader Service Card MASA-Yards Delivers Carnival's Superliner, 70,000-GRT Fantasy MASA-Yards, New Helsinki Shipyard delivered the 70,000-grt superliner Fantasy to Carnival Cruise Lines, Miami, Fla. The construction of the vessel had been begun by Finland's Wartsila Marine Industries before the shipbuilder had declared bankruptcy.

The 855-foot, 2,600-passenger vessel is one of the most expensive ships ever built.

The 14-passenger deck Fantasy features 2 x 14 MW Cyclo propulsion drives, 6.6 kv switchboards, four 10.3 MVA main and two 6.8 MVA auxiliary generators, plus six thruster motors and the main transformers, all engineered and supplied by ABB Marine of Helsinki. Six Wartsila-Sulzer diesel engines with a total of more than 57,000 bhp are the prime movers of the diesel-electric propulsion system. The Fantasy is also fitted with two highly skewed KaMeWa controllable-pitch propellers.

MASA-Yards has secured the contract for the second CCL liner Ecstacy.

For free literature detailing the shipbuilding services of MASAYards, Circle 7 on Reader Service Card Ulstein Hatlo Completes Conversion Of Alaskan Factory Stern Trawler Last year, Norway's Ulstein Hatlo shipyard delivered the converted American Dynasty, a 272-foot U.S.

factory stern trawler, to her owner American Seafoods Company.

Operating off the coast of Alaska in the Bering Sea, the American Dynasty can produce up to 100 tons of surimi per day. The surimi is a fish paste used in substitute seafood production.

The vessel is powered by a pair of Bergen Diesel main engines, rated at 4,000 bhp at 750 rpm, driving an Ulstein CP propeller.

Other equipment aboard the vessel includes an Atlas freshwater generator, Norwinch main trawl winches, MacGregor cargo lift, and Simrad sonars and echo sounder.

For free literature detailing the conversion capabilities of Ulstein Hatlo, Circle 8 on Reader Service Card Wartsila Diesel Expands In North America —Literature Offered— Wartsila Diesel, one of the world's largest manfacturers of mediumspeed diesel engines, has relocated its North American and Caribbean sales and service operations to Chestertown, Md. With the consolidation of all functions of Wartsila Diesel, Inc., in one central location, they will be better positioned to serve the expanding market in the Western Hemisphere for high-quality, advanced-design, medium-speed diesel engines powered by heavy fuel and natural gas.

Wartsila Diesel currently sells diesel engines from 788 to 22,000 h o r s e p o w e r in two primary markets—marine and land-based power generation.

In the marine market, Wartsila Diesel supplies propulsion and power generating engines for all types of ships, from tugs and fishing vessels to tankers, containerships and cruise ships. With the current emphasis on efficiency and economy, Wartsila Diesel engineers are developing complete machinery packages including reduction gears, propellers, and control systems. Their goal is to optimize the balance among all on-board space components for maximum economies of operation.

For free literature detailing the complete line of diesel engines from Wartsila Diesel for the marine market, Circle 90 on Reader Service Card James Marino Named Sales Manager At Navionics Riva Schwartz, president of the newly formed Navionics, Inc., has appointed James Marino to the position of sales manager. Mr.

Marino, who brings to Navionics an extensive background in sales and marketing in the computer and electronic equipment industry, will be responsible for the North American market.

Following graduation from Boston University, Mr. Marino became senior marketing representative at Xerox Corporation, where he was responsible for maximizing market share, customer satisfaction and return on assets. While at Xerox, he twice achieved the President's Club Award For Outstanding Performance.

Mr. Marino then developed computer-based telemarketing and product performance tools for BIS/ CAP International in Norwell, Mass.

Ms. Schwartz stated, "Mr.

Marino's proven marketing talents in the high-tech arena will make him an asset both to Navionics as well as to the marine electronics industry." For free literature giving more information on Navionics, Circle 2 1 on Reader Service Card Texas A & M At Galveston To Get Norcontrol Diesel Engine Simulator Engineering students at Texas A&M University at Galveston, Texas, (TAMUG) will soon be able to simulate a ship's engine room in the classroom with a new $205,900 Norcontrol Diesel Engine Simulator which will be installed at the Mitchell Campus on Pelican Island.

According to Prof. William C.

Van Loo of the TAMUG engineering department, the equipment can compress years of experience into a few weeks of training and can give the student an easier introduction to background theories.

The configuration of the simulator is that the instructor is equipped with shipshape consoles and panels arranged in a realistic environment, while the students are furnished with color graphic displays and keyboards.

The system is also applicable for simulation of the deck operation of the ship, which will allow students who are training toward licenses as third mates to experience the "bridge" relationship with the engine room.

For free literature from Norcontrol giving full information on equipment and services, Circle 35 on Reader Service Card ScanRope Introduces Two New Mooring Ropes ScanRope a/s, one of Norway's largest manufacturers of wire ropes and fiber ropes, has introduced two new mooring ropes in the market, based on its successful Karat fiber.

The products are "Karatlas," and "18Karat." Karatlas is a sixstrand wire rope laid rope with a combination of Karat-fiber and thick monofilaments. The manufacturer reports the main benefit is its structural stability, which allows it to be used on self-tensioning winches in several layers without crushing or jamming. It has low elongation and excellent abrasion resistance.

Until now, this rope has been produced with nylon fiber only. Karatlas weighs less and is therefore more economical.

With 18Karat, ScanRope uses a process that covers the outer yarn in the Karat Maxi hawser with a thin mantle of polyester. This gives an optimal combination of Karat's very high strength with Polyester's excellent abrasion properties. ScanRope indicates at least a 50 percent increase in abrasion resistance when compared to ordinary Karat, polypropylene, etc., but with only a small cost increase.

A new brochure, "Shipping Ropes For The 90's," explaining all these products in detail, is now available from ScanRope. For a free copy, Circle 104 on Reader Service Card

Read EUROPEAN SHIPBUILDING AND REPAIR in Pdf, Flash or Html5 edition of May 1990 Maritime Reporter

Other stories from May 1990 issue

Content

- 21 -Percent Increase In World Shipbuilding Output Reported page: 6

- MSI-Operated CAORF Facility Selected To Assess Operational Impact Of New BC Superferries page: 6

- PBI Awards $2.8-Million Order To MagneTek ALS page: 7

- Free Literature Offered On New Navy-Approved Fire Retardant Coating page: 8

- Conoco Inc. Orders Two Double-Hull Tankers From Samsung Shipbuilding page: 9

- DRS Offers Advanced Sonar Signal And Video Processing Systems page: 9

- Guthans Elected AWO Chairman Of The Board; Farrell Reelected President page: 10

- Webb Institute Receives Endowment For Professorship From Lester Rosenblatt page: 10

- Wartsila Marine-Powered Floating Power Plant Barge Built By Conrad Industries, Outfitted By Bollinger page: 10

- Blount Marine Launches Excursion Boat Spirit of Boston page: 11

- EUROPEAN SHIPBUILDING AND REPAIR page: 12

- Unitor Offers Literature On New Medical Concept For Cruise Industry page: 22

- Bird-Johnson Pneumatic Systems To Be Installed By PCE On 18 Navy LSTs page: 23

- Huge Train Ferry 'Railship III' Powered By Wartsila Diesels page: 24

- Hover Systems/Eastern Shipyards Announce Air Cushion Vehicles Licensing Agreement page: 24

- STATUS REPORT ON U.S. NAVY SHIP AND EQUIPMENT PROCUREMENT page: 27

- Trinity To Build Fifth Army LSV Under $10-Million Pact page: 34

- MTU, KaMeWa To Supply Propulsion Machinery For Repowering U.S. Navy SES-200 page: 34

- Wilson & Hayes Mark 55 Years In Business page: 34

- Fairbanks Morse Receives Order For 16 Engines From Avondale page: 37

- L&C Associates Installs Protective Sealing System Aboard USNS Mispillion page: 37

- Posidonia The International Shipping Exhibition page: 38

- Furmanite Offers Free Brochure Describing Machines And Services page: 41

- International Paint Applies New Coating Technology To U.S. Marine Market page: 42

- Nichols Bros. Delivers First 3 Of 6 Ferries For Puerto Rico page: 43

- Eastern Shipyards Converts Two Offshore Vessels To Ensco Marine page: 43

- RORO90 page: 44

- Textron Marine Systems Delivers LCAC-24 To U.S. Navy page: 45

- Cummins-Powered Yacht At Freeport Shipbuilding page: 45

- Bender Monitoring Systems Prevent Ground Faults —Literature Available page: 45

- Free Brochure Details Rigid Inflatable Craft From Task Force Boats page: 45

- Construction Of Cog Replica Supported By Deutz M WM page: 46

- Ingalls To Continue Engineering, Planning Services To N a v y 's Aegis Destroyer Program page: 46

- Jeffboat Names Ken Howe Manager, Marine Repair page: 47

- E-A-R's Type II Vibration Damping Tiles Hold Navy QPL Status page: 47

- Hopeman Brothers To Supply Accommodation Joiner Packages For Two Oil Skimming Vessels page: 50

- Master Marine Building 100-Foot Fiberglass Trawler For Alaska Fisheries page: 55