Dredger: 9-Year Wear Life on Cutterhead Shaft Bearings

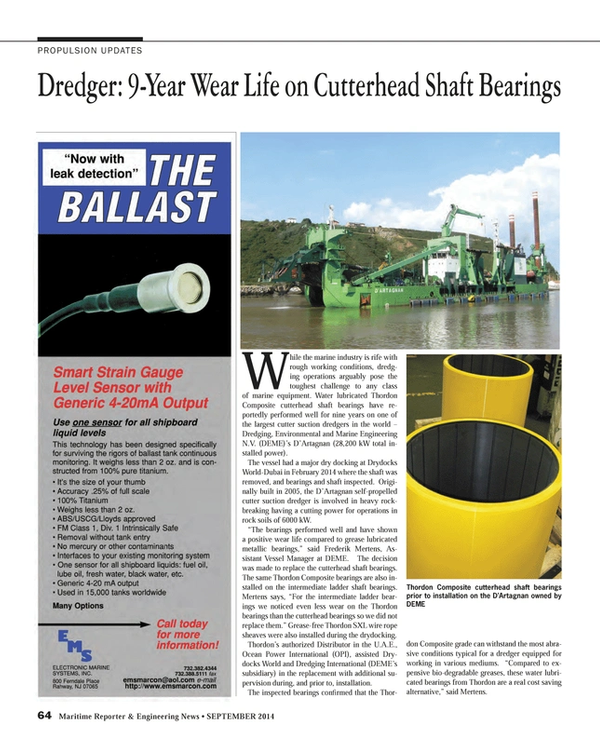

While the marine industry is rife with rough working conditions, dredging operations arguably pose the toughest challenge to any class of marine equipment. Water lubricated Thordon Composite cutterhead shaft bearings have reportedly performed well for nine years on one of the largest cutter suction dredgers in the world –Dredging, Environmental and Marine Engineering N.V. (DEME)’s D’Artagnan (28,200 kW total installed power).

The vessel had a major dry docking at Drydocks World-Dubai in February 2014 where the shaft was removed, and bearings and shaft inspected. Originally built in 2005, the D’Artagnan self-propelled cutter suction dredger is involved in heavy rock-breaking having a cutting power for operations in rock soils of 6000 kW.

“The bearings performed well and have shown a positive wear life compared to grease lubricated metallic bearings,” said Frederik Mertens, Assistant Vessel Manager at DEME. The decision was made to replace the cutterhead shaft bearings. The same Thordon Composite bearings are also installed on the intermediate ladder shaft bearings. Mertens says, “For the intermediate ladder bearings we noticed even less wear on the Thordon bearings than the cutterhead bearings so we did not replace them.” Grease-free Thordon SXL wire rope sheaves were also installed during the drydocking.

Thordon’s authorized Distributor in the U.A.E., Ocean Power International (OPI), assisted Drydocks World and Dredging International (DEME’s subsidiary) in the replacement with additional supervision during, and prior to, installation.

The inspected bearings confirmed that the Thordon Composite grade can withstand the most abrasive conditions typical for a dredger equipped for working in various mediums. “Compared to expensive bio-degradable greases, these water lubricated bearings from Thordon are a real cost saving alternative,” said Mertens.

(As published in the September 2014 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)

Read Dredger: 9-Year Wear Life on Cutterhead Shaft Bearings in Pdf, Flash or Html5 edition of September 2014 Maritime Reporter

Other stories from September 2014 issue

Content

- Exporting Crude Oil A “No-Brainer” page: 8

- New DeepFlight Dragon Personal Sub page: 13

- New Possibilities for Imaging Measurement page: 14

- Unpredictable & Dangerous Rogue Waves page: 16

- How Specialty Lenders Can Propel Marine Operators page: 18

- SAMI On Top Line Security Concerns page: 20

- Is the US Prepared to Protect Its Arctic Interests? page: 24

- Russian Class & Arctic Operations page: 28

- What's New in Floating Production? page: 38

- Design’s Future 3D Modeling, Virtual Reality Wave of Design Future page: 40

- Caterpillar for Vessel Driving Power page: 46

- Waterjets Manufacturing Comes Stateside page: 50

- U.S. Maritime Security: The Portunus Concept page: 52

- VADM Hilarides Commander, Naval Sea Systems Command page: 56

- The New Pipeline page: 58

- Volvo Penta's New Keel Cooling Option page: 63

- Emissions Scrubber Receives Class Approval page: 63

- Dredger: 9-Year Wear Life on Cutterhead Shaft Bearings page: 64

- Low Loss Hybrid Energy System page: 65

- GreenSteam Optimizer page: 66

- New Power for Alaskan Tug page: 67

- New LED Light Range page: 70

- Trojan Marinex BWTS is USCG Approved page: 70

- New VDR Tech from Danelec page: 70

- DMC Builds the Smallest Ever Nozzle page: 70

- Victaulic Launches Portable Roll Groover page: 71

- New Electronics from Moxa page: 71

- Calnetix Waste Energy Converter page: 71

- GEA’s CatFineMaster page: 71