Alert in Valdez Harbor

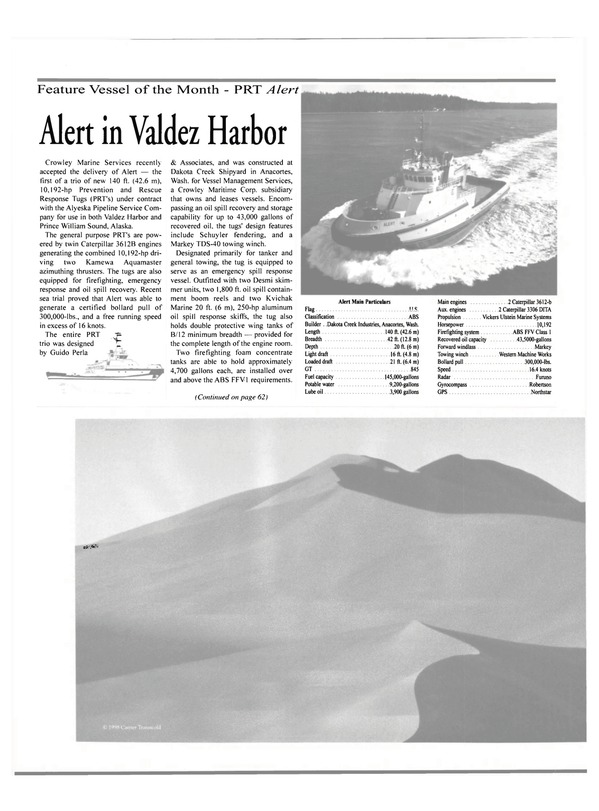

Crowley Marine Services recently accepted the delivery of Alert — the first of a trio of new 140 ft. (42.6 m), 10,192-hp Prevention and Rescue Response Tugs (PRT's) under contract with the Alyeska Pipeline Service Company for use in both Valdez Harbor and Prince William Sound, Alaska.

The general purpose PRT's are powered by twin Caterpillar 3612B engines generating the combined 10,192-hp driving two Kamewa Aquamaster azimuthing thrusters. The tugs are also equipped for firefighting, emergency response and oil spill recovery. Recent sea trial proved that Alert was able to generate a certified bollard pull of 300,000-lbs., and a free running speed in excess of 16 knots.

The entire PRT trio was designed t by Guido Perla & Associates, and was constructed at Dakota Creek Shipyard in Anacortes, Wash, for Vessel Management Services, a Crowley Maritime Corp. subsidiary that owns and leases vessels. Encompassing an oil spill recovery and storage capability for up to 43,000 gallons of recovered oil, the tugs' design features include Schuyler fendering, and a Markey TDS-40 towing winch.

Designated primarily for tanker and general towing, the tug is equipped to serve as an emergency spill response vessel. Outfitted with two Desmi skimmer units, two 1,800 ft. oil spill containment boom reels and two Kvichak Marine 20 ft. (6 m), 250-hp aluminum oil spill response skiffs, the tug also holds double protective wing tanks of B/12 minimum breadth — provided for the complete length of the engine room.

Two firefighting foam concentrate tanks are able to hold approximately 4,700 gallons each, are installed over and above the ABS FFV1 requirements.

Accommodating 16 people including spill response personnel in two single, five double and one quadruple berth staterooms, remaining accommodation spacing are situated with a galley and pantry with cold storage, ship's office and decontamination station.

Responsible for the design of this vessel series is Seattle-based naval architectural firm Guido Perla & Associates (GPA). who took the responsibility for regulatory compliance by entering plans to ABS for U.S. and International Tonnage Certificates. The firm's engineers worked to perform the structural and mechanical calculations, electronic load analysis, and short circuit analysis and drew up a fire and safety plan. GPA engineers also created composite drawings with machinery and wiring layouts and piping routing for the equipment, ensuring that construction and operational maintainability was free of interference.

Prior to construction, an automated layout of the vessel confirmed mechanical capability, while ensuring a working view of towing operations from the pilothouse. This 3-D computer model of the complete design was formulated using the latest releases of AutoCAD, Rhino, AccuRender, as well as GPAdeveloped software. Exporting this computerized information to GPA's 40- station network allowed for development of hull scientific, structural, mechanical and electrical designs. The company provided lines fairing, lofting and numerical control NC tapes for automated burning and marking of individual parts.

Circle 87 on Reader Service Card

Read Alert in Valdez Harbor in Pdf, Flash or Html5 edition of March 2000 Maritime Reporter

Other stories from March 2000 issue

Content

- A broader-based payback from R&D page: 8

- An Effective Shield from Criminal Prosecution page: 14

- MARCO Signs Contract With S.F. Bar Pilots page: 16

- MAN Acquires Alstom Diesel Engine Ops page: 16

- South Korean January Ship Orders Increase page: 17

- Dockwise Awarded Hanjung Contract page: 17

- The U.S. Navy - Reducing Shipboard Planned Maintenance page: 20

- Safety Charter Targets Old Tankers, Flags Of Convenience page: 20

- High Times Again in Singapore? page: 22

- Ship Repair Yards Ask: Where's the Funding? page: 26

- Ailsa-Troon Continues To Climb page: 27

- Irving Shipbuilding Repairs Wide Selection page: 29

- Vessels Make Pit Stop At Bay Ship page: 30

- Tampa Bay Shipbuilding - Gearing Up For A Boom page: 31

- Bollinger Puts Its Expertise To The Test page: 32

- Turbo-Technik: Rescuing A "Prinsesse" page: 33

- Smooth Sailing page: 34

- Seacoast Delivers Package To Halter page: 34

- JRC Radar Offers Plotter System page: 34

- SKYbolt Enables Real Time Processing page: 38

- Transas Moves Towards Auto Integrated Navigation page: 44

- Litton To Supply For New Passenger Ferries page: 44

- Riverboat Casino Ratings Buoyed by Regulations, Demand page: 48

- Washburn & Doughty: Developing New Process To Meet Changing Needs page: 49

- Fictitious Tugboat Character Goes Live In Canada Yard page: 51

- Bollinger opts for Oracle page: 52

- BIMCO Introduces Millennium Software page: 55

- Ship Safety Database Set Up To Avoid Future Disasters page: 55

- WindShip Technology Promises Fuel Saving s page: 56

- Recore Classified As Fireproof For Vessels page: 56

- Sandwiched Composites Offer Promise For Marine Industry page: 57

- Fiberline Offers GRP For Use In Hostile Environs page: 57

- AMT Marine To Construct Utility Boat page: 59

- Sneed Delivers Pushboat To Blessey Marine page: 59

- Alert in Valdez Harbor page: 60

- 3.MAJ Delivers Innovative Tanker page: 61

- Robert Allan Design To Be Built For Brusco page: 62

- New Surface Cleaning Process Saves Navy On Maintenance page: 65

- Jotun Goes Tin-Free page: 66

- Se-Cliff Enhances With CoreKote 2000 page: 69

- Japan: Advanced procedures sustain industry in turbulent markets page: 74

- JAMSTEC Deepsea Exploring Ship Contract Announced page: 75

- Power management with distributed intelligence page: 76

- Chamber Of Shipping Requests Entries page: 77

- The Erika oil spill - using the incident to positive effect page: 80

- NCL Board Dumped, Lund Appointed page: 92

- Litton Integrates Marine Ops In New Company page: 92