Oerlikon Opens $7-Million U.S. Manufacturing And Laboratory Plant For Welding Consumables

Dignitaries from the international and national welding and business communities recently gathered in Houston, Texas, for the commissioning ceremony of Oerlikon Welding Industries's new $7-million welding consumables manufacturing facility.

Oerlikon Welding Industries (OWI), an Oerlikon-Buehrle Group Company, will serve as the North American headquarters for the welding division of Oerlikon-Buehrle, multibillion- dollar Swiss parent company with diversified product groups throughout the world.

OWI's new 58,000-square-foot manufacturing facility is one of the first new flux manufacturing plants to be built in the U.S. in over 20 years. It utilizes a unique high-temperature flux drying kiln designed exclusively by Oerlikon.

In addition to submerged arc flux, OWI will also manufacture a complete selection of covered electrodes.

James T. Hickey, vice president and general manager, introduced guest speakers M. D. Randall, 1983-84 president of the American Welding Society, and Dr. Herbert Menzi, head of welding industries Oerlikon- Buehrle Ltd. in Zurich, Switzerland. In his speech, Dr. Menzi cited Oerlikon-Buehrle commitment to the American market and pledged full support to OWI's product development.

He then flicked a switch and Oerlikon's manufacturing facility roared into production.

Following the opening ceremony, guests were taken on tours of Oerlikon's plant and laboratory facilities to become acquainted with the many technical aspects and manufacturing processes associated with the production of submerged arch fluxes and covered electrodes.

According to Mr. Hickey, OWI has outfitted one of the most impressive welding laboratories in the Southwest. Analytical equipment includes an ARL inductively coupled plasma spectrometer for analysis of aciddissolved alloy samples; a DIANO XRD-8565 X-ray fluorescence analyzer for both metallic and non-metallic material analysis; a LECO PTF 700 induction melting furnace; and LECO EC 12 carbon analyzer for infrared analysis of carbon levels down to parts per million.

The Oerlikon laboratory represents a $1- million investment to ensure quality consumables and services. In addition to monitoring its manufacturing procedures, Oerlikon plans to contract technical services to welding fabrication industries, research organizations, metallurgical industries, and steel-making foundries.

Read Oerlikon Opens $7-Million U.S. Manufacturing And Laboratory Plant For Welding Consumables in Pdf, Flash or Html5 edition of August 1983 Maritime Reporter

Other stories from August 1983 issue

Content

- IThe First Annual International Inland Waterways Conference & Trade Show page: 6

- NASSCO Holds Christening For Second Ingram-Class Tanker page: 14

- Dravo Offers Free 66-Page Color Brochure Describing Towboat & Barge Designs page: 15

- Genstar Appoints West Executive Vice President page: 15

- SNAME Panel SP-8 Members Survey NASSCO's Productivity Gains page: 16

- Oerlikon Opens $7-Million U.S. Manufacturing And Laboratory Plant For Welding Consumables page: 17

- Moran Appoints Two Top Executives page: 18

- Moss Point Marine Delivers Nicor Clipper- Largest Offshore Tug/Supply Vessel Built In The U.S. page: 22

- Lehman N a m e d Manager M a r i n e A n d Industrial Sales At E l e c t r o - M o t i ve page: 23

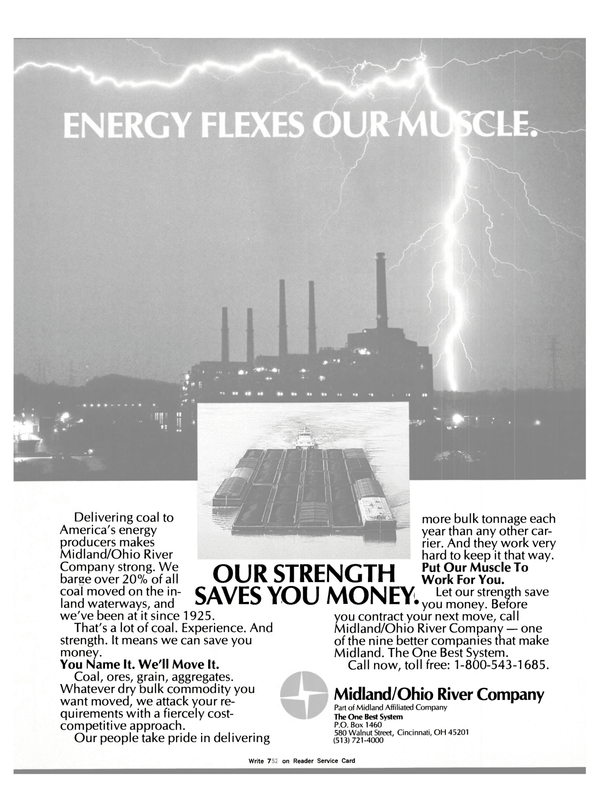

- M i d l a n d A f f i l i a t e d O f f e rs Brochure O n Inland W a t e r w a y s Services page: 23

- DECK MACHINERY A REVIEW page: 24

- Swiftships Delivers Second 117-Foot Tug To Otto Candies page: 52

- First Guyed Tower Platform Installed In Gulf of Mexico page: 52

- $ 4 - M i l l i o n C o n t a i n e r s h i ps S e p a r a t o r C o n t r a ct A w a r d e d A l f a - L a v al page: 53

- AWO Higher User Taxes Would Be Bad Economics page: 55

- Halter Marine Building Diesel-Electric Sternwheeler For 1984 World's Fair page: 58

- Newport News Completes Annual Overhaul Of Cruise Liner Veendam In 12 Days page: 63

- FMC Delivers Third Hydraulic Dump Barge To Smith-Rice page: 63

- $186-Million Contract To Convert Tanker Into Hospital Ship Awarded To National Steel page: 68

- Halifax Industries Celebrates Inauguration Of Floating Dock —Brochure Offered On Facilities page: 68

- Bender Delivers First Five Of Twenty Shrimp Boats For Guyana page: 69

- George Fegert Honored For Work With Shipyard Conference page: 74

- MSC And Ocean Carriers Sign $250-Million T-5 Tanker Pact page: 74

- Tuna Clipper Saves 80,000 Gallons Of Fuel On One Trip—Literature Available page: 74