First Guyed Tower Platform Installed In Gulf of Mexico

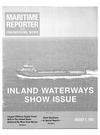

Exxon USA recently installed the world's first commercial guyed tower offshore platform in 1,000 feet of water in a new gas and oil field southeast of New Orleans in the Gulf of Mexico. Total development cost for the field is in excess of $750 million.

The new platform design significantly reduces the construction cost of platforms for use in water depths approaching 2,000 feet, compared with conventional fixed platforms. Cost efficiencies result from the use of less structural steel in the guyed tower.

For stability, a conventional platform is designed to be rigid when exposed to environmental forces. This causes the platform to be considerably wider at the bottom than at the top. The guyed tower, by contrast, is 120 feet square along its 1,078-foot length and is designed to move with wind and wave forces.

Steel piles attach the tower to the ocean floor similar to a conventional platform. A network of 20 guylines arranged symmetrically around the tower and anchored into the ocean floor keeps the structure from overturning.

The guying system allows the tower to comply—to move slightly—and then return to its normal position as environmental forces vary.

Each guyline extends about 1,800 feet from the tower to a 200 ton weight. Known as clump weights, they are built in segments and joined together much like links in a bicycle chain. As waves or winds move the tower, the cable will lift segments in the clump weight and then set them down when the tension relaxes.

A test model's performance indicates that the deck will move less than three feet off center 99 percent of the time. Even in a hurricane with winds of 130 mph and waves about 70 feet high, the tower will be resilient. The deck could move as far as 40 feet off center without damaging the tower's pilings or breaking a guyline.

In 1981, construction of the tower began at Brown & Root's fabrication yard at Port Aransas, Texas, near Corpus Christi. The tower weighs 27,000 tons and has more than 15 miles of welds. Once completed, the structure—with decks and drilling rigs added atop the tower—will be 1,300 feet tall, approximately the height of a 100- story building.

It took a five-day voyage on a launch barge nearly as long as two football fields to carry the tower to a new oil and gas field in Mississippi Canyon Block 280, about 110 miles southeast of New Orleans.

Because of the length of the tower, the launch barge was modified to tip the tower into the Gulf off the side, instead of the end, as is usually done. The side launch reduces the risk of damage to the tower and the barge. It also eliminates the need for about 3,000 tons of additional steel to reinforce the tower for an end launch. After launch, the guylines were securely attached to the tower.

Later this summer the three deck levels will be brought to the site by barge and lifted into place.

The two acres of deck space will hold two drilling rigs, production equipment, and living quarters for up to 140 people during the first years of operation.

Development drilling from the guyed tower platform should begin in late 1983, with production starting in 1984. A total of 58 production wells are planned for the field. Including drilling, pipelines, and other development costs, the guyed tower project will represent an investment of more than $750 million.

Read First Guyed Tower Platform Installed In Gulf of Mexico in Pdf, Flash or Html5 edition of August 1983 Maritime Reporter

Other stories from August 1983 issue

Content

- IThe First Annual International Inland Waterways Conference & Trade Show page: 6

- NASSCO Holds Christening For Second Ingram-Class Tanker page: 14

- Dravo Offers Free 66-Page Color Brochure Describing Towboat & Barge Designs page: 15

- Genstar Appoints West Executive Vice President page: 15

- SNAME Panel SP-8 Members Survey NASSCO's Productivity Gains page: 16

- Oerlikon Opens $7-Million U.S. Manufacturing And Laboratory Plant For Welding Consumables page: 17

- Moran Appoints Two Top Executives page: 18

- Moss Point Marine Delivers Nicor Clipper- Largest Offshore Tug/Supply Vessel Built In The U.S. page: 22

- Lehman N a m e d Manager M a r i n e A n d Industrial Sales At E l e c t r o - M o t i ve page: 23

- M i d l a n d A f f i l i a t e d O f f e rs Brochure O n Inland W a t e r w a y s Services page: 23

- DECK MACHINERY A REVIEW page: 24

- Swiftships Delivers Second 117-Foot Tug To Otto Candies page: 52

- First Guyed Tower Platform Installed In Gulf of Mexico page: 52

- $ 4 - M i l l i o n C o n t a i n e r s h i ps S e p a r a t o r C o n t r a ct A w a r d e d A l f a - L a v al page: 53

- AWO Higher User Taxes Would Be Bad Economics page: 55

- Halter Marine Building Diesel-Electric Sternwheeler For 1984 World's Fair page: 58

- Newport News Completes Annual Overhaul Of Cruise Liner Veendam In 12 Days page: 63

- FMC Delivers Third Hydraulic Dump Barge To Smith-Rice page: 63

- $186-Million Contract To Convert Tanker Into Hospital Ship Awarded To National Steel page: 68

- Halifax Industries Celebrates Inauguration Of Floating Dock —Brochure Offered On Facilities page: 68

- Bender Delivers First Five Of Twenty Shrimp Boats For Guyana page: 69

- George Fegert Honored For Work With Shipyard Conference page: 74

- MSC And Ocean Carriers Sign $250-Million T-5 Tanker Pact page: 74

- Tuna Clipper Saves 80,000 Gallons Of Fuel On One Trip—Literature Available page: 74