The Lure of the Electric Drive

In the September 2002 issue of Maritime Reporter and Engineering News, a detailed discussion was featured on the advantages of future High Temperature Superconductor (HTS) machinery for propulsion of electric drive ships. Since then, development of HTS ship propulsion motors has moved ahead — at a rapid pace — specifically in three areas: • Motors A 5-MW 230-rpm machine for the U.S. Navy's Office of Naval Research (ONR) is undergoing factory tests. ONR is now funding the next step - design, fabrication and factory testing of a 36.5-MW 120-rpm machine to prove the technology at full-scale for warships.

• Generators Development of HTS generators has also leapt ahead with the initial production of 10-MVAR synchronous condensers for utility voltage adjusting service. These condensers are very similar in design and operation to 10-MW, 1,800-rpm generators.

• Very large systems HTS technology is particularly well-suited to high torque marine propulsion systems, and the small size, light weight, high efficiency and inherent quietness offer unique solutions to propulsion of very fast and very large ships.

While diagnostic devices using superconducting magnets are common in hospitals and some industrial applications, virtually all rely on low temperature superconductor wire that must be maintained within a few degrees of absolute zero to function. Commercially available high temperature superconducting wire, developed over the past decade at American Superconductor Corporation (AMSC), achieves superconductivity at temperatures up to 100 degrees above absolute zero, in the vicinity of the temperature of liquid nitrogen. While very cold by human standards, this temperature is easy and inexpensive to achieve and maintain. Commercially available refrigerator systems and straightforward insulation systems combine to make HTS superconducting machinery practical and affordable in any industrial setting, including ship propulsion.

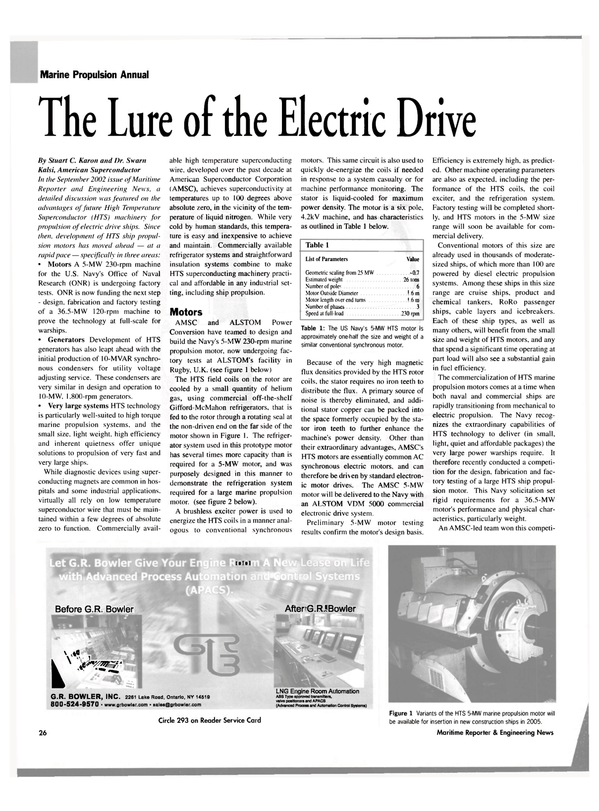

Motors AMSC and ALSTOM Power Conversion have teamed to design and build the Navy's 5-MW 230-rpm marine propulsion motor, now undergoing factory tests at ALSTOM's facility in Rugby, U.K. (see figure 1 below) The HTS field coils on the rotor are cooled by a small quantity of helium gas, using commercial off-the-shelf Gifford-McMahon refrigerators, that is fed to the rotor through a rotating seal at the non-driven end on the far side of the motor shown in Figure 1. The refrigerator system used in this prototype motor has several times more capacity than is required for a 5-MW motor, and was purposely designed in this manner to demonstrate the refrigeration system required for a large marine propulsion motor, (see figure 2 below).

A brushless exciter power is used to energize the HTS coils in a manner analogous to conventional synchronous motors. This same circuit is also used to quickly de-energize the coils if needed in response to a system casualty or for machine performance monitoring. The stator is liquid-cooled for maximum power density. The motor is a six pole, 4.2kV machine, and has characteristics as outlined in Table 1 below.

Because of the very high magnetic flux densities provided by the HTS rotor coils, the stator requires no iron teeth to distribute the flux. A primary source of noise is thereby eliminated, and additional stator copper can be packed into the space formerly occupied by the stator iron teeth to further enhance the machine's power density. Other than their extraordinary advantages, AMSC's HTS motors are essentially common AC synchronous electric motors, and can therefore be driven by standard electronic motor drives. The AMSC 5-MW motor will be delivered to the Navy with an ALSTOM VDM 5000 commercial electronic drive system.

Preliminary 5-MW motor testing results confirm the motor's design basis.

Efficiency is extremely high, as predicted.

Other machine operating parameters are also as expected, including the performance of the HTS coils, the coil exciter, and the refrigeration system.

Factory testing will be completed shortly, and HTS motors in the 5-MW size range will soon be available for commercial delivery.

Conventional motors of this size are already used in thousands of moderatesized ships, of which more than 100 are powered by diesel electric propulsion systems. Among these ships in this size range are cruise ships, product and chemical tankers, RoRo passenger ships, cable layers and icebreakers.

Each of these ship types, as well as many others, will benefit from the small size and weight of HTS motors, and any that spend a significant time operating at part load will also see a substantial gain in fuel efficiency.

The commercialization of HTS marine propulsion motors comes at a time when both naval and commercial ships are rapidly transitioning from mechanical to electric propulsion. The Navy recognizes the extraordinary capabilities of HTS technology to deliver (in small, light, quiet and affordable packages) the very large power warships require. It therefore recently conducted a competition for the design, fabrication and factory testing of a large HTS ship propulsion motor. This Navy solicitation set rigid requirements for a 36.5-MW motor's performance and physical characteristics, particularly weight.

An AMSC-led team won this competi- tion, has proven its HTS design algorithms and technology in the Navy's 5- MW program, and is now applying its HTS design algorithms and technology to the design and fabrication of a 36.5- MW (49,000-shp) 120-rpm motor. This motor is sized for the Navy's future DD(X) class ships, and its delivery is scheduled for spring 2006. The design effort is proceeding in accordance with the proposed schedule, and the program is on track to deliver the motor on time.

Read The Lure of the Electric Drive in Pdf, Flash or Html5 edition of September 2003 Maritime Reporter

Other stories from September 2003 issue

Content

- New SWATH From ACMA page: 8

- IZAR Delivers LNG Inigo Tapias page: 10

- Wallace McGeorge Modified for Deep Dredging page: 11

- Careful, Your Species May Be Non-Indigenous page: 12

- U.S. Sub Christened in "Home" Port page: 16

- HSV 2 Swift Delivered to U.S. Navy page: 17

- A Change in Course page: 18

- Univan Reports Steady Growth page: 20

- Payload Pivotal to Fast Sealift Ship page: 24

- The Chairman's Influence on Design page: 24

- The Lure of the Electric Drive page: 26

- Very Large Systems page: 27

- Generators And Synchronous Condensers page: 27

- Cat Power For Unique Boat page: 30

- MAN B&W Flexibility With Two Strokes page: 31

- "Ink" It In: WMTC a Must for Maritime Professionals page: 34

- Guido Perla: Colombian Born, American Made page: 38

- Thrane & Thrane Offers the Capsat Fleet33 page: 42

- SeaWave Family Designed for Ease of Use page: 42

- PGS Geophysical Renews With Telenor page: 43

- Nera F 5 5 Terminal Gets Inmarsat Type Approval page: 44

- Monitoring Technology...Advanced page: 45

- Outlook for Floating Production Systems page: 52

- Meyer Werft Delivers to RCCL page: 57