Geometry at the Heart

Computational geometry is at the heart of much of MARIN’s day-to-day business

Computational geometry is at the heart of much of MARIN’s day-to-day business, which includes the hull, appendages and propulsion design and optimization, to the milling of models and detailed CFD calculations. And computational geometry is also set to play a key role in longer-term research and development carried out by MARIN, its clients and partners.

In 2012, MARIN started a new, long-term project to update and expand its geometry capabilities for hulls, appendages and propellers. The aim is to enable designers, CAD and CFD users to model and optimize their designs effectively and interface them with the outside world: from geometry input to analysis, (CFD) calculations and model production.

New propulsion design tools

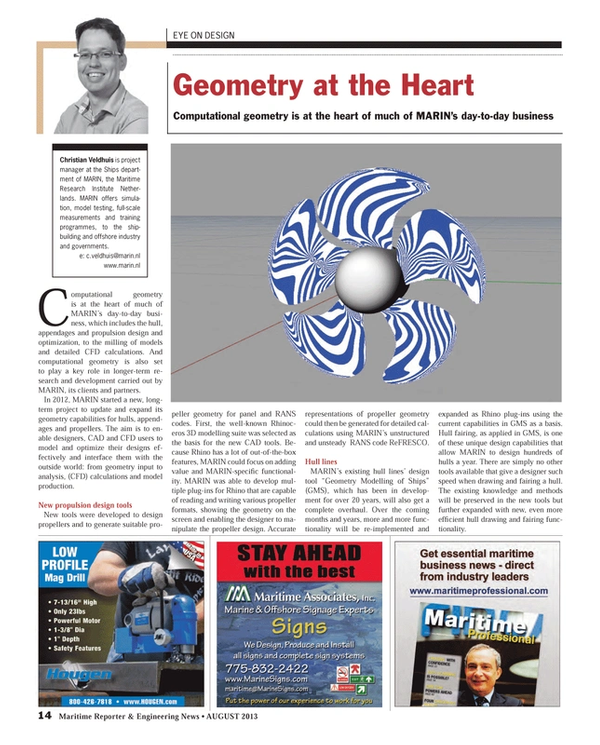

New tools were developed to design propellers and to generate suitable propeller geometry for panel and RANS codes. First, the well-known Rhinoceros 3D modelling suite was selected as the basis for the new CAD tools. Because Rhino has a lot of out-of-the-box features, MARIN could focus on adding value and MARIN-specific functionality. MARIN was able to develop multiple plug-ins for Rhino that are capable of reading and writing various propeller formats, showing the geometry on the screen and enabling the designer to manipulate the propeller design. Accurate representations of propeller geometry could then be generated for detailed calculations using MARIN’s unstructured and unsteady RANS code ReFRESCO.

Hull lines

MARIN’s existing hull lines’ design tool “Geometry Modelling of Ships” (GMS), which has been in development for over 20 years, will also get a complete overhaul. Over the coming months and years, more and more functionality will be re-implemented and expanded as Rhino plug-ins using the current capabilities in GMS as a basis. Hull fairing, as applied in GMS, is one of these unique design capabilities that allow MARIN to design hundreds of hulls a year. There are simply no other tools available that give a designer such speed when drawing and fairing a hull. The existing knowledge and methods will be preserved in the new tools but further expanded with new, even more efficient hull drawing and fairing functionality.

Christian Veldhuis is project manager at the Ships department of MARIN, the Maritime Research Institute Netherlands. MARIN offers simulation, model testing, full-scale measurements and training programs, to the shipbuilding and offshore industry and governments.

e: [email protected] • www.marin.nl

(As published in the August 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)

Read Geometry at the Heart in Pdf, Flash or Html5 edition of August 2013 Maritime Reporter

Other stories from August 2013 issue

Content

- Alion Ramp Makes for Safer Ship-to-Ship Transfers page: 11

- From ShipConstructor to SSI page: 12

- Geometry at the Heart page: 14

- Training Challenges page: 16

- Maintenance & Certification: Critical to the Safety of Life at Sea page: 18

- The Busy Signal page: 20

- Satellite Radar page: 24

- Offshore Wind Market Report $19.8B Opportunity page: 30

- Offshore Deepwater Brazil Sevan Drilling’s Big Dig page: 32

- Gulf Copper Keeps “Calm” page: 34

- Eastern: Beyond the Backlog page: 36

- Brasa: FPSO Modules a Specialty page: 38

- ASRY: Bucking the Slowdown Trend page: 41

- Austal USA Powers Ahead page: 42

- Signal International page: 50

- Vessel Ordering Mania – Why? page: 51

- TNG: Talleres Navales Del Golfo page: 52

- Vigor Industrial page: 54

- Maintaining the Ship of Mercy page: 56

- Tips on Reducing Ship Operating Costs page: 58

- Schottel Celebrates CPP Milestone page: 63

- Siemens: Gigantic Gear Unit Technology page: 64

- Book Review: “After the Galaxy” page: 68

- Pipe Joining: Testing Times for Seaworthy Products page: 74