Optimizing Feed Rates For Crosshead Diesels

New program analyzes scrapedown oil as way to detect changes in the condition of an engine's cylinders ExxonMobil introduced a program to optimize cylinder oil feed rates in low-speed (crosshead) diesel engines. The "Feed Rate Optimization" program is designed to help minimize operating expenses by analyzing scrapedown oil as a way to detect changes in the condition of an engine's cylinders. The program, which is designed to help customers find a balance between the cost of cylinder oil and the expense of wear-related cylinder maintenance, analyzes scrapedown oil collected from the engine's scavenge space, a technique pioneered by ExxonMobil. It is designed to provide comprehensive laboratory testing and analysis of the oil sample, and offers onboard testing tools that enable ship's engineers to quickly detect substantive changes in cylinder condition.

The new program features: • Signum Oil Analysis: ExxonMobil has extended its existing Signum Oil Analysis program, which can help forecast potential mechanical problems before they occur, to include scrapedown testing. This extensive laboratory analysis provides insight into engine wear via the condition of a vessel's scrapedown oil.

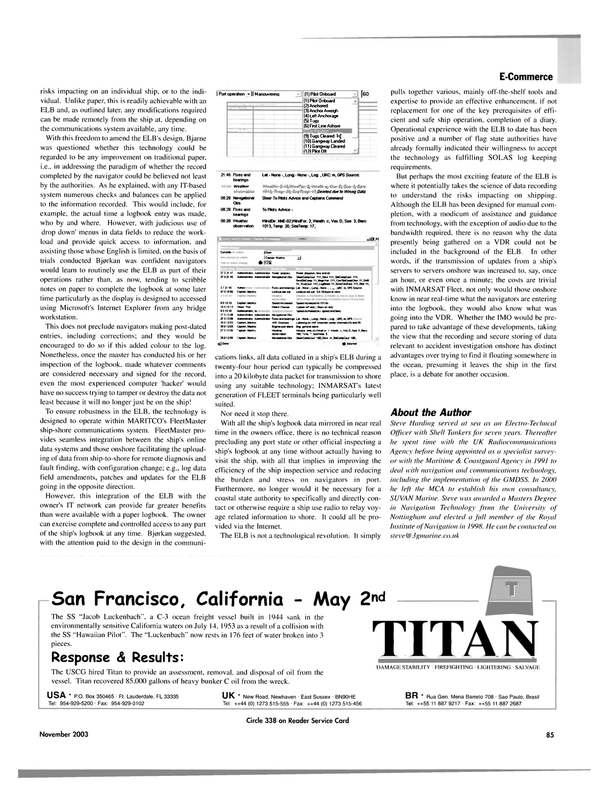

• Onboard testing: Onboard testing tools include a proprietary Mobilgard Scrapedown Analyzer (pictured), a portable unit that enables a ship's engineer to quickly analyze the current wear rate of each cylinder.

For customers who do not want to wait for a comprehensive lab report, onboard testing provides real-time readouts on the oil's most important properties relativ e to the engine's operating condition.

• Quality oil: ExxonMobil recommends Mobilgard 570, a cylinder oil formulated at an optimized viscosity level with high quality base oil to provide excellent thermal and oxidation stability, and protection against engine deposit and wear. It is proven to provide lowspeed.

two-cycle crosshead diesel engines with these performance features even as lower feed rates are adopted.

The new Feed Rate Optimization program was developed with the support of the major engine manufacturers, including MAN B&W and Wlirtsila.

"Changes in cylinder wear due to engine operation, ambient conditions and fuel sulfur levels can be detected as they are occurring, particularly if onboard sample analysis is employed," says Kjeld E. Aabo, senior manager engineering services. MAN B&W Diesel A/S.

"Advanced warning of cylinder condition, as seen through scrapedown oil analysis results, allows the operator to optimize feed rates while ensuring optimum engine performance." Following are some answers to common questions regarding the new system.

Q: Why did ExxonMobil Marine Lubricants introduce a "Feed Rate Optimization" program?

A: The trend toward increased size and speed of general cargo ships and container vessels mandates the continued domination of this segment by low-speed (crosshead) diesel engines, which can burn less-expensive residual fuel oil more efficiently and reliably than can other types of engines. At the same time, manufacturers have changed their engines dramatically over the past 20 years, and the new higher output designs for greater efficiency hav e greatly increased stress on the cylinder oil. Reduced cylinder oil consumption rates made possible by new feed system designs hav e further stressed the oil.

Environmental regulations and variations in HFO (heavy fuel oil) characteristics around the world have resulted in increasing numbers of engines operating on low-sulfur-content HFO. This can result in sudden wear if feed rates and lubricant selection are not properly balanced. A program to safely optimize cylinder oil feed rates against these variables while monitoring the condition of the engine's cylinders can help ship owners find an acceptable balance between the cost of the cylinder oil and the expense of wear-related cylinder maintenance. Identifying that balance can reduce total operating costs.

Q: Why is analyzing scrapedown oil so important?

A: With the use of cylinder scrapedown oil analysis (the analysis involves various tests of used oil as a way to monitor the condition of the engine and the lubricant).

it is possible to reduce cylinder oil feed rates to provide the optimum balance of cylinder oil and engine component replacement cost. Shipboard personnel can monitor the condition of an engine's cylinders and detect changes as they occur.

Q: What kind of laboratory tests does ExxonMobil perform?

A: For many years. ExxonMobil has been using Signum Oil Analysis to help customers monitor the performance and condition of lubricants, engines and equipment. The Signum program has been expanded to include analv sis of scrapedown cylinder oil. A comprehensive slate of laboratory tests includes: Inductively Coupled Plasma Emission Spectroscopy (which monitors wear metals - including iron, a primary wear indicator, and phosphorus, an indicator of system oil contamination); Physical and/or Chemical Analysis (which measures the total base number, viscosity and water as indicators of oil degradation and contamination); Particle Quantifier (which monitors abrasive wear): and Ferrography (which helps identify wear type and cause). Oil samples are sent from shipboard to an ExxonMobil laboratory. The program automatically reports trends and compares variables such as iron, base number, load, fuel sulfur and humidity.

Findings can help identify wear indicators before problems occur. And they can be used to optimize cylinder oil feed rate, minimizing the overall cost of operations.

Q: What kind of testing can take place aboard ship?

A: The Feed Rate Optimization program includes an option for onboard testing that is particularly useful for customers who do not want to wait for a comprehensive lab report. ExxonMobil provides the onboard tools for ship personnel to test the most important properties relative to wear and optimizing feed rates. A Mobilgard Scrapedown Analyzer (MSA) instantly measures and displays the iron content of a used cylinder oil sample. A Signum Onboard Test Kit monitors lubricants for alkalinity retention (TBN). water contamination and changes in viscosity. A MSA Logbook enables crewmembers aboard ship to store results, graph trends and analyze relationships between variables.

The tools are designed to be easy to use.

Q: What is the advantage of onboard testing?

A: Speed is the primary advantage. Onboard testing augments and complements the more comprehensive Signum laboratory testing with supplementary reports that are especially useful because they provide key results in a matter of seconds. Speedy access to technical data means that shipboard personnel can make feed rate adjustment decisions quickly. If the testing equipment alerts a ship's engineer to substantive changes in cylinders, he can take immediate corrective action before any problems become serious. Speed in detecting changes is important because wear can occur rapidly in two-stroke engines.

Q: What was the involvement of major engine manufacturers?

A: The new program was developed after cooperative testing with the major engine manufacturers. Says Matthias Amoser. manager Tribology and Material Technology. Wartsila Switzerland. Ltd. "Our experience has shown that the analysis of scrapedown cylinder oil can provide many clues regarding the operation of the engine, the impact of varying fuel sulfur levels, the effect of feed rate, and also, can serv e as an early warning to potential undesirable wear situations. A frequent onboard analysis program supplemented by land-based laboratory analysis provides key information for monitoring piston running experience." Circle 6 0 on Reader Service Card

Read Optimizing Feed Rates For Crosshead Diesels in Pdf, Flash or Html5 edition of November 2003 Maritime Reporter

Other stories from November 2003 issue

Content

- EU Single-Hull Phase-Out Elicits I MO Scorn page: 10

- Costa Victoria in for a Facelift page: 11

- Sustainable Growth for Liner Shipping page: 11

- World's Biggest LNG Carrier Due in 2005 page: 12

- Shipbreaking in the Spotlight at ILO page: 14

- Signet Martime Inks Garrett Contract page: 16

- IZAR Enters Fast Ship Project page: 17

- TEN Signs Time Charter for Aframax Olympia page: 17

- Cruise Port Expenditure to Reach $300M page: 18

- At Sea with U.S. Maritime Security page: 20

- NY Navigation Channels: The Really Big Dig page: 25

- Kvichak Delivers for NY page: 28

- Vosta LMG signs U.S. contract for 18" Cutter Suction Dredge design page: 28

- Senesco Marine Christens New Drydock page: 29

- Workboat Annual 2003 • Great Boats of 2003 page: 30

- Natter Passes Command of Atlantic Fleet page: 41

- Introducing Lean Shipbuilding to U.S. Yards page: 42

- IBM PLM Offers New Shipbuilding Solutions page: 46

- Cosco Dalian Leads China Ship Repair Business page: 50

- China: Growing Influence in All Matters Maritime page: 52

- L'Orange at Marintec China 2003 page: 56

- Shiport China 2004: Set in Tune with the Shipbuilding Industry page: 57

- New Aluminum Marine Alloy Specification Developed page: 58

- InspecTech Launches Line of "Smart" Windows page: 62

- New CEO at Kvaerner Philadelphia page: 62

- Asheim Takes Helm of Hoegh Fleet page: 62

- New Potency in Electronic Control page: 68

- Research as the Building Block page: 70

- Knowledge Interchange page: 71

- Surface-Protection Symposium Set for Liibeck page: 78

- Xybernaut Gets Patent for Detecting Corrosion on Maritime Vessels page: 79

- LCS Hull Concept Tests Move Ahead page: 80

- Hypertherm Enters Laser Cutting Market page: 81

- E-Ship: The Paperless Trail page: 82

- Cradle Tweendecks Patent for Langh Ship page: 86

- Optimizing Feed Rates For Crosshead Diesels page: 88

- Benjamin Vickers: 175 Years & Counting page: 89

- Life Boats by Ernst Hatecke Make the Plunge page: 90

- Clean Seal Celebrates 25 Years page: 91

- Netherlands Vessel First With New Engine page: 92

- ONR To Evaluate SeaCoaster page: 92

- KMY Helps Breaks the Ice in Russia page: 97

- Astander Completes CSO Deep Pioneer Upgrade page: 97

- Rickmers Singapore Christened page: 97

- Transas Releases New Version of Engine Room Simulator page: 98

- Merseyside gets first UK escort tug simulator page: 98