Coal-Fired Marine Boilers

A Coal-Fired Marine Steam Plant Can Be Offered Today Which Will Provide The Same High Traditional Reliability.

The origin of the steam boiler can be directly related to the invention of the steam engine, and its development has been a vital element in the successful generation of power by steam.

The earliest types of marine boilers consisted of large pressure vessels filled with water with external furnaces located underneath and were fired with solid fuels; initially wood and then coal.

Eventually the well-known Scotch marine boiler evolved and was readily accepted by marine engineers.

As the demand for larger and faster vessels grew, power demands also increased. At the end of the nineteenth century, the development of the steam turbine by Sir Charles Parsons prompted even further demands on the boiler designer. Improved materials led to increased capacities, pressures, and temperatures. Stiff commercial as well as naval competition urged the development of newer boiler designs. Various types of water-tube boilers were initially adopted because of their ability to fit into restricted spaces.

Oil firing of marine boilers began to appear around the turn of the century. Although not readily accepted initially, the advantages of firing oil gradually became more apparent and it eventually became the standard for most vessels. Oil not only proved more convenient to handle, store, bunker, and burn; but it also proved more convenient from a manpower utilization standpoint. By the end of World War II, coal firing was essentially phased out of most vessels. One area of exception was the Great Lakes. Because of the longevity of these vessels, their somewhat limited trade routes, and their easy access to coal, many of these vessels continued to operate on coal.

During the 1960s and early 1970s, there was a great demand for increased speed. Fuel oil was relatively inexpensive and readily available. Larger and faster merchant vessels were constructed, and more advanced plants utilizing higher temperatures and pressures were adopted.

In 1973, the Arab oil embargo created conditions which required a complete re-evaluation of vessel operation and design. Throughout the remainder of the 1970s, the price of crude oil continued to rise at unprecedented rates. Also during the latter part of the 1970s, political unrest in the Middle East made the availability of crude oil uncertain.

Concern over meeting energy demands became paramount. Both government and industry began to investigate alternate energy sources and their possible application to particular energy demands.

Although there appear to be many alternate energy sources which can assist in solving this problem in the future, such as synfuels, solar power, fusion, etc., these will be of little assistance to the marine operator in the near future.

One alternate fuel that is readily available, and is suitable for marine applications, particularly in light of the economic and political factors which are currently affecting oil, is coal.

Therefore, in evaluating any powerplant for a vessel today, an operator must consider the future availability of his fuel source, its quality, and the effect its price might have on the operation of the vessel. In such an evaluation, the economics for certain types of vessels appear to justify considering coal-fired steam plants.

Methods Of Coal Firing Three methods of coal firing are presently available to the marine boiler designer for his consideration: pulverized firing, fluidized bed combustion and stoker firing. The use of coal-oil slurries may be considered as a fourth alternate, however, this method of firing requires many of the ancillary components indigenous to the coal-fired plants such as ash handling equipment, coal pulverizers and stack-gas cleanup equipment, as well as a rather large furnace. Due to the large quantity of oil (50 percent to 60 percent) required in the slurry, the same economics associated with full coal firing cannot be realized. This method of firing is currently in use to a small extent in the utility and industrial section as a retrofit for plants originally designed to fire oil. The capacity of these plants retrofitted for slurry firing would be approximately 40 percent less than with oil firing.

Pulverized firing involves the suspension firing of coal which has been reduced in size by a bowl mill or other form of coal pulverizer to a powder consistency.

This method of firing is a virtual necessity for plants designed to produce more than 300,- 000 pounds of steam per hour, since a stoker for this application would be impractical due to its large size. The pulverized system requires a significantly greater volume for a given machinery installation due to additional fuel preparation and transport equipment as well as a 20 percent larger furnace volume than for stoker firing.

Fluidized bed combustion, wherein fuel is introduced into an aerated bed of limestone, sand or suitable material and burned at temperatures usually in the range of 1,600°F, may ultimately have application in the marine sector. The principal advantage would be its somewhat compact furnace size relative to either stoker or pulverized-coal firing as well as pollution control potential.

At the present time, this concept is largely experimental in nature with only a few demonstration plants of relatively low capacity in actual operation.

Stokers are mechanical devices used to burn solid fuels. They perform the primary function of converting chemical energy in the fuel to thermal energy which is absorbed by the boiler surfaces to generate steam.

The ability of the stoker to handle a wide range of coals makes it particularly attractive for marine application since coal analyses will vary widely at the bunkering ports. Furthermore, since a stoker requires a relatively coarse fuel mixture, fuel preparation equipment onboard a ship may be non-existent or, at the most, consist of a simple coal crusher.

These points, as well as the inherent ruggedness and simplicity of the stoker, make it ideal for marine application.

Boiler Design The most basic design consideration for any steam-generating unit is the fuel to be burned. Furnace size, fuel burning and preparation equipment, heating surface qantity and placement, heatrecover equipment and air-pollution control devices vary considerably among units, depending on the kind of fuel being used. The major differences between coal firing and oil or natural-gas firing steam generators are a result of the solid form of coal prior to burning and the ash contained in the products of combustion. The products of combustion from burning oil contain relatively small amounts of ash, and natural gas produces no ash. Coal must be stored, conveyed, and pulverized or crushed before being introduced into the furnace, whereas oil and gas, by comparison, require very little preparation.

Coal-fired steam generators, because of the time required for burnout of the solid coal particles, must have much larger furnaces than oil or gas-fired steam generators for a given output. Figure 1 dramatizes the general differences in furnace size required between coal-fired design and oil or gas fired design for the same steaming capacity.

Because of the ash present, velocities of the products of combustion as they pass through the steam generator heating surfaces must be lower for coal-fired units than oil-fired units, thereby requiring significantly greater clearances between tubes. Coal-fired steam generators also require ashhandling equipment and may require stack-gas cleanup equipment not normally required for an oil or gas-fired unit.

Since there are many different types of coals available, the design and operation of a steamgenerating unit is significantly influenced by various coal properties.

An examination of the coal properties from many different parts of the U.S. indicates the wide variation in heating values, moisture content, and consequently the pounds of fuel that must be fired to generate the same power.

The heating values range from 12,000 Btu/pound for an Eastern bituminous coal to 6,800 Btu/ pound for Northern Plains lignite.

There are also coals in the U.S.

that range down below 4,000 Btu/ pound. Moisture content ranges from six percent for Eastern bituminous to 37 percent for the Northern Plains lignite. The related moisture per million Btu's for this range varies from five to 54 pounds. The indicated range of coal-firing rates (16,700 to 30,- 600) to yield comparable heat inputs for a nominal unit provides a comparison of the coal storage and handling equipment requirements for the various coals.

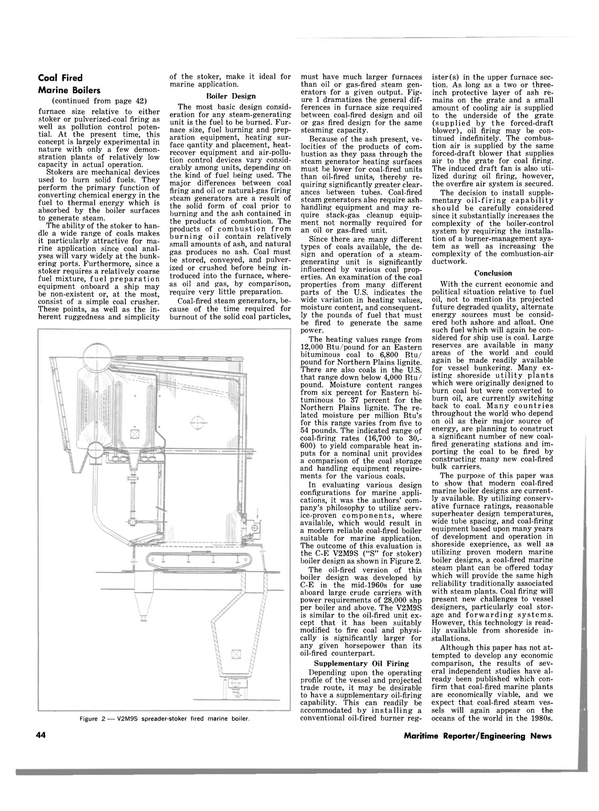

In evaluating various design configurations for marine applications, it was the authors' company's philosophy to utilize service- proven components, where available, which would result in a modern reliable coal-fired boiler suitable for marine application.

The outcome of this evaluation is the C-E V2M9S ("S" for stoker) boiler design as shown in Figure 2.

The oil-fired version of this boiler design was developed by C-E in the mid-1960s for use aboard large crude carriers with power requirements of 28,000 shp per boiler and above. The V2M9S is similar to the oil-fired unit except that it has been suitably modified to fire coal and physically is significantly larger for any given horsepower than its oil-fired counterpart.

Supplementary Oil Firing Depending upon the operating profile of the vessel and projected trade route, it may be desirable to have a supplementary oil-firing capability. This can readily be accommodated by installing a conventional oil-fired burner register (s) in the upper furnace section.

As long as a two or threeinch protective layer of ash remains on the grate and a small amount of cooling air is supplied to the underside of the grate (supplied by the forced-draft blower), oil firing may be continued indefinitely. The combustion air is supplied by the same forced-draft blower that supplies air to the grate for coal firing.

The induced draft fan is also utilized during oil firing, however, the overfire air system is secured.

The decision to install supplementary o i l - f i r i n g capability should be carefully considered since it substantially increases the complexity of the boiler-control system by requiring the installation of a burner-management system as well as increasing the complexity of the combustion-air ductwork.

Conclusion With the current economic and political situation relative to fuel oil, not to mention its projected future degraded quality, alternate energy sources must be considered both ashore and afloat. One such fuel which will again be considered for ship use is coal. Large reserves are available in many areas of the world and could again be made readily available for vessel bunkering. Many existing shoreside utility plants which were originally designed to burn coal but were converted to burn oil, are currently switching back to coal. Many countries throughout the world who depend on oil as their major source of energy, are planning to construct a significant number of new coalfired generating stations and importing the coal to be fired by constructing many new coal-fired bulk carriers.

The purpose of this paper was to show that modern coal-fired marine boiler designs are currently available. By utilizing conservative furnace ratings, reasonable superheater design temperatures, wide tube spacing, and coal-firing equipment based upon many years of development and operation in shoreside exeprience, as well as utilizing proven modern marine boiler designs, a coal-fired marine steam plant can be offered today which will provide the same high reliability traditionally associated with steam plants. Coal firing will present new challenges to vessel designers, particularly coal storage and forwarding systems.

However, this technology is readily available from shoreside installations.

Although this paper has not attempted to develop any economic comparison, the results of several independent studies have already been published which confirm that coal-fired marine plants are economically viable, and we expect that coal-fired steam vessels will again appear on the oceans of the world in the 1980s.

Read Coal-Fired Marine Boilers in Pdf, Flash or Html5 edition of August 1980 Maritime Reporter

Other stories from August 1980 issue

Content

- Tracor Offering Paper On Integrated Navigation Systems page: 5

- J.J. Bajor Will Head Newly Formed Keppel Marine Agencies Inc. page: 5

- Equitable Delivers Multipurpose Cargo Vessel M / V Amazonia page: 6

- Red Fox Will Build Jackup Barges At Newly Acquired Yard page: 6

- James Steadman Joins Halter Marine As VP For Special Assignments page: 6

- New Jackup Drill Rig Christened At Beaumont Yard Of Bethlehem Steel page: 8

- Patrick Keene Named Director Of Operations At Ingalls Shipbuilding page: 8

- Simrad Introduces New Trawl Echo Recorder- Literature Available page: 8

- Robert Strasser Joins MacGregor, U.S.A. As Technical Director page: 8

- Three Free Reports A v a i l a b l e From Ship Structure Committee page: 9

- Strickland Appointed Director Of Salvage For Crowley Maritime page: 9

- Bird-Johnson Appoints Richard E. McGinnis A Trustee And Director page: 9

- Halifax Shipyards Gets C$27-Million Order For Three Stern Trawlers page: 9

- Peterson Delivers Big Tuna Seiner, Launches Another page: 10

- Advanced Design Product Tanker Launched At Sun Ship page: 10

- Coast Guard Approves Butterworth Systems Oil/Water Separators page: 10

- New Bulletin Describes Improved Diesel Cylinder Liner Plating Process page: 10

- G.F. Price Appointed VP Of Lykes Bros. Marine Division page: 12

- Army Permit Clears W a y For Deep-Draft Terminal In Galveston page: 12

- Shipyard Finds Safe Product Without Sacrificing Performance page: 12

- HUDSHIP Enters Export Market With Offshore Supply Vessel page: 13

- Zapata To Acquire Offshore Services Ltd. From Trafalgar House page: 13

- Furuno Announces New Model Radar Alarm- Literature Available page: 14

- Agri-Trans Announces Five Key Promotions In Management Staff page: 14

- Improved Sales And Earnings Reported By Todd Shipyards—Has $1,5-Billion Backlog page: 15

- ITO Announces Six Promotions—R.J. Nolan Named Executive VP page: 15

- Technical Report On Sea-Shed Conversions Available From MarAd page: 15

- Ogden Equips Fleet With Satellite Navigators page: 15

- Nav-Com Relocates To Larger Quarters page: 16

- $4.7-Million Contract Awarded By U.S. Navy To Savannah Machine page: 18

- Maumenee, Roy And Snellman Promoted At Alabama Dry Dock page: 18

- Appledore And DnV To Assist In Operation Of Okpo Shipyard page: 18

- Michigan Wheel Announces Formation Of Propulsion Systems Group page: 18

- Marland Has New MSD For Smaller Vessels- Literature Available page: 20

- Waller & Associates To Provide Engineering Services For Ingram page: 20

- Two Hitachi Yards Deliver Bulker And Product Carrier page: 21

- San Francisco To Build New Fireboat Designed By Morris Guralnick page: 21

- Halter Delivered 30 Big Commercial Vessels In First Half Of 1980 page: 22

- James Rhodes Appointed Communications Director For Navidyne Corp. page: 22

- French Appointed VP-Program Support At Sun Ship—Three Other Support Posts Filled page: 23

- Dieselcare 80 Seminar Scheduled In New York October 28-29, 1980 page: 24

- B&W Yard Given Danish Gov't Guarantee For Bulk Carrier Construction page: 24

- Transoceanic Designated As U.S. Forwarder For NACAP Project page: 26

- Griff Lee, McDermott VP, Elected To National Academy Of Engineering page: 28

- James J . Murphy Named VP-Marketing For General Dynamics' Marine Group page: 28

- New Report Confirms Fuel Efficiency In All Transport Modes page: 29

- Lucander And Dowhos Form Design Association page: 29

- $278-Million Contract Awarded To Wartsila By V /O Sudoimport page: 30

- PSI Announces Contracts For ACOE Dredges page: 31

- Maritime Association Names Parkhill New President, Buckley, VP page: 31

- American Manufacturing Announces Three Sales Appointments page: 32

- Gene Ossi Establishes New Automation Firm- Brochure Available page: 32

- Trikora Lloyd Buys Three Ships At Total Cost Of $45 Million page: 32

- Michael Warren Joins Farboil As National Accounts Manager page: 32

- FMC Launches Big Deck Barge For Puget Sound Freight Lines page: 34

- Joy Manufacturing Has Literature Available On New Clutch Assembly page: 34

- Brochure Available On JLG Industries' Aerial Work Platforms page: 34

- Dravo SteelShip Delivers Towboat To Pleasants Power Station page: 34

- Dillingham Forms New Subsidiary To Operate In Gulf Coast Area page: 34

- Hydranautics Awarded BP Magnus Field Platform Contract page: 34

- Collins Elected President And General Manager Of Houston Systems Mfg. page: 34

- Multipurpose Cargo Vessel 'Sarita' Delivered By Hitachi page: 34

- Haggerty Joins APL As Managing Director Of Atlantic Region page: 35

- IHI Awarded Contract To Build Two VLCCs For Kuwait Government page: 37

- Gillen's Names Three To New Executive Posts page: 37

- Raymond To Join In Building $30-Million Yard In Malaysia page: 37

- David Jackson Appointed Vice President For Sun State Marine page: 37

- New MMC Gauging System Meets IMCO Guidelines- Literature Available page: 37

- K.J. Funk Named VP-Sales, E.F. Carrigan Sales Director For Jeffboat page: 38

- Thomas A. King Named New Superintendent Of Merchant Marine Academy page: 38

- Farrell Lines Announces Three New Appointments— Breslin To VP-Controller page: 38

- Gaston Joins Bulkfleet Marine As Manager Of Engineering Services page: 38

- C.A. Tomassoni Joins Designers & Planners In Design/Economics Post page: 39

- Garlock Introduces Asbestos-Free Packing —Literature Available page: 39

- Hamburg To Host World's First Trade Fair On Port Planning/Operations page: 39

- Three New Managers Appointed By CDI Marine Company page: 39

- Hayward Marine Products New Name For Former Mechanical Marine page: 39

- Miles Heads Barber Blue Sea Activities In North America page: 40

- First Vessel Extruded From Covered Hall At Cammell Laird page: 40

- $79-Million Jackup Rig Ordered By Nedlloyd From Hitachi Zosen page: 41

- McDermott Division Gets Two Contracts For Irish Sea Gas Projects page: 41

- Coal-Fired Marine Boilers page: 42

- Cameron Refits Drill Rig 'Western Pacesetter II' In Record-Breaking Five Days page: 42

- New Company Plans To Build Two Bulk/Container Ships At Cost Of $156 Million page: 42

- Evergreen Handt Merged Into Evergreen Marine— Hansen Named President page: 44

- Carriere Named Manager Of Lykes M&R Division In San Francisco page: 44

- German Yard Launches U.S.-Flag Trailership page: 48

- IMODCO Gets $14-Million Mooring Terminal Job Offshore Abu Dhabi page: 50

- Brochure Available On Six Operating Divisions Of Grinnell Valve page: 51

- New Zapata Tug Tows Crewboat To West Africa page: 52

- Unique Supply Lighter Launched By MARCO Seattle page: 52

- I.C. Kizilkaya And John Slager Have Joined Designers & Planners, Inc. page: 53