Allison I m p l e m e n t s Performance, M a i n t e n a n c e , Reliability Improvements In M a r i n e Gas Turbines

The Allison Gas Turbine Division of General Motors has extended its product improvement efforts to the 501-KF and 570-KF marine gas turbine engines for increased reliability and maintainability of these highpower density, simple-cycle units.

501-KF The 501-KF engine is successfully used in the Boeing "Jetboil" passenger ferry. The arrangement is a 501- KF engine on each side of the vessel driving a Rocketdyne PJ20 waterjet.

The engines develop 4,330 continuous shaft horsepower each and are available with various improvements to enhance their capability.

Recent options released to the 501- KF include: • Split Outer Combustion Case— Allows access to combustion liners without engine removal.

• Low Emission Combustion Liners— Combines the need for low emissions with improved life through optimizing flame profile and thermal barrier coatings.

• Closed Loop Electronic Control— Improves fuel system per- formance by integrating speed and turbine gas temperature to provide stable efficient power.

• Turbine Gas Temperature measured at Interstage Point—Increases thermocouple life.

The engine is also employed as a single prime mover on the Grumman M161, 105-ton hydrofoils. This application uses bevel gearing for reduction and drives a single propeller for speeds up to 52 knots.

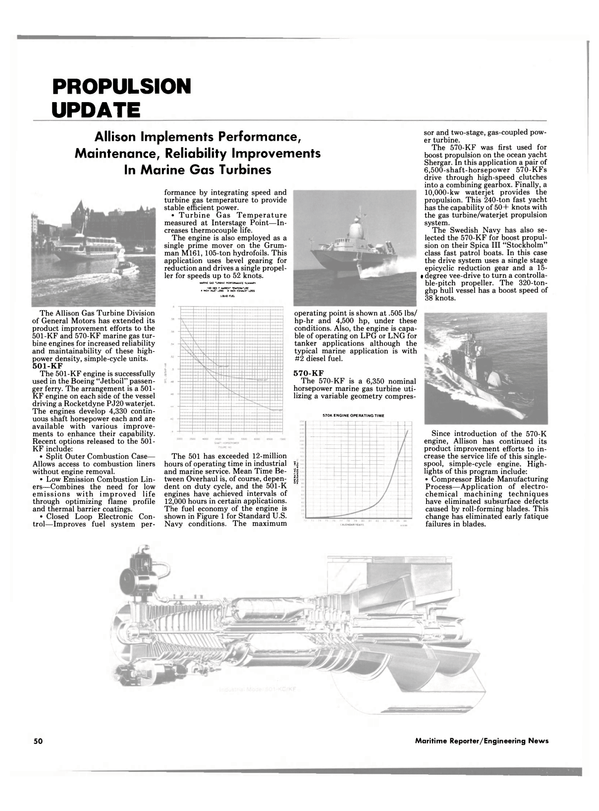

The 501 has exceeded 12-million hours of operating time in industrial ?§ and marine service. Mean Time Be- tween Overhaul is, of course, depen- dent on duty cycle, and the 501-K engines have achieved intervals of 12,000 hours in certain applications.

The fuel economy of the engine is shown in Figure 1 for Standard U.S.

Navy conditions. The maximum operating point is shown at .505 lbs/ hp-hr and 4,500 hp, under these conditions. Also, the engine is capable of operating on LPG or LNG for tanker applications although the typical marine application is with #2 diesel fuel.

570-KF The 570-KF is a 6,350 nominal horsepower marine gas turbine utilizing a variable geometry compres- sor and two-stage, gas-coupled power turbine.

The 570-KF was first used for boost propulsion on the ocean yacht Shergar. In this application a pair of 6,500-shaft-horsepower 570-KFs drive through high-speed clutches into a combining gearbox. Finally, a 10,000-kw waterjet provides the propulsion. This 240-ton fast yacht has the capability of 50+ knots with the gas turbine/waterjet propulsion system.

The Swedish Navy has also selected the 570-KF for boost propulsion on their Spica III "Stockholm" class fast patrol boats. In this case the drive system uses a single stage epicyclic reduction gear and a 15- t degree vee-drive to turn a controllable- pitch propeller. The 320-tonghp hull vessel has a boost speed of 38 knots.

Since introduction of the 570-K engine, Allison has continued its product improvement efforts to increase the service life of this singlespool, simple-cycle engine. Highlights of this program include: • Compressor Blade Manufacturing Process—Application of electrochemical machining techniques have eliminated subsurface defects caused by roll-forming blades. This change has eliminated early fatique failures in blades.

• Combustor Development—The annular combustion liner was redesigned (for the Royal Canadian Defense Forces) to eliminate visible smoke. This improvement is now being used on all 570-K engines.

• Turbine Hot Section—Blade cooling has been improved with modified air passages. Vane life has been extended through material changes and cooling techniques.

• Thrust Balancing—570 engines now use a tilting pad thrust bearing system mounted aft of the power turbine that absorbs the 6,000- pounds of axial load in the power turbine. The effect of this change has more than doubled shaft bearing life.

The 570 has been selected by the Canadian Navy for cruise power on their 5,000-ton Tribal class destroyer.

The vessels are scheduled for updating and modernization beginning in 1987 when a pair of 570- KF engines will be installed in each.

A major improvement was implemented this year when Allison introduced the Model 571-KF engine.

This engine shares the gas generator design with the 570, but has a threestage power turbine. It is 20 percent more powerful and 12 percent more fuel efficient. The engine has a continuous standard day, no-loss rating of 7,694 shaft horsepower and can operate in excess of 8,000 shp intermittently.

The 571 was field-tested for over 900 hours prior to shipment of the first production unit in January 1986. Meanwhile 570-K engines have accumulated over 220,000 total hours of service time. The improvement mentioned above will allow that total to increase rapidly.

ALLISON GAS TURBINE COLOR BROCHURES AVAILABLE Three full-color well-illustrated brochures completely describing the Allison gas turbine line are available at no cost. For copies, circle the appropriate number(s) on the reader service card in the back of this issue.

501-K—A Spectrum of Power— 12 pages, full-color, describes all eight models in the 501-K series.

Contains photographs, full-color cutaway illustrations, performance tables, specification tables and examples of applications.

C i r c l e 5 7 on Reader Service Card 570-K and 571-K—Power for the Future—12 well-illustrated full-color pages. Complete data on these dual-shaft engines include photos, illustrations, performance graphs and specification tables.

C i r c l e 5 8 on Reader Service Card 501-K and 570-K—16 full-color pages. Photos, cutaway color illustrations, mechanical drawings, performance graphs, specification tables and material specifications.

Modular design is illustrated—details include reduced maintenance factors, distribution capibilities, field support, options, etc.

C i r c l e 5 9 on Reader Service Card

Read Allison I m p l e m e n t s Performance, M a i n t e n a n c e , Reliability Improvements In M a r i n e Gas Turbines in Pdf, Flash or Html5 edition of July 15, 1986 Maritime Reporter

Other stories from July 15, 1986 issue

Content

- FlightSafety Orders Shiphandling Simulator From Tracor Hydronautics page: 4

- Valmet And Wtirtsilti To Merge Shipbuilding Operations In One Group page: 5

- Dillingham Restructures West Coast Operations— Key Executives Named page: 5

- Falmouth Shiprepair Moves Ahead Again With Major N e w Agreement page: 6

- Nippon Kokan To Market Titanium-Clad Steel Plate Produced By Hot Rolling page: 6

- Freeport Shipbuilding Delivers Passenger Vessel To Nassau Cruises page: 7

- Franklin Promoted To Vice President At McDermott Marine page: 7

- U.S. NAVY SHIP MAINTENANCE AND MODERNIZATION page: 8

- MAJOR NAVY CONTRACTS page: 11

- DIESEL POWER REVIEW page: 18

- M e y e r W e r f t Y a r d Delivers Luxury Cruise Ship ' H o m e r i c ' To H o m e Lines page: 30

- Coast M a r i n e Celebrates 4 0 - Y e a r A n n i v e r s a r y W i th Successful Ladder Drop Test page: 30

- Bailey Announces Sales Management Appointments page: 31

- Free Brochure Details Delaval's OEM Overhaul Of U.S. Navy Equipment page: 31

- S N A M E Lakes/Rivers Section Holds Spring M e e t i n g In Louisville page: 32

- S t a n d a r d - C : Low-Cost Satellite Communications Terminal page: 32

- Port Of Portland Reports Soaring Imports Of Cars From Japan And Korea page: 34

- Miller Electric Offers New Diesel Welding Generator page: 34

- S.S. White Offers Free Brochure On Flexible Reach Rods page: 35

- NASSCO Appoints Janice S. Shanklin page: 35

- Lorenz, Trotter And Waldorf Named To Zapata Board Of Directors page: 35

- Sea-Land Unit Restructured — B a k e r Appointed Vice Chairman And COO page: 36

- Goltens Uses Diversity To Seek New Markets page: 36

- ACBL Rechristens Three N e w l y Acquired River Towboats page: 36

- Marathon LeTourneau Awarded Contract For Platform Rig Project page: 36

- MTCR Introduces N e w Shipboard E n g i n e e r i n g T r a i n i n g Systems page: 37

- Sanborn Named President Of Sonat Marine Inc. page: 38

- Sperry Introduces A d v a n c ed S a t e l l i t e Communicators page: 38

- W a r t s i l a Diesel Introduces A N e w Compact V 8 Engine page: 39

- Sembawang Diversifies Into Salvage And Towing page: 39

- Cat Pumps Introduces Corrosion-Resistant Line page: 39

- Report O n The N e w M a g n a v ox GPS Positioning & N a v i g a t i o n System page: 40

- Tenn-Tom Development Conference Scheduled For October 22-24 In Knoxville page: 40

- Pekka Laine Appointed Managing Director Of New Wartsila/Valmet Company page: 40

- Combustion Engineering A w a r d ed $ 7 M i l l i o n In N a v y Boiler Contracts page: 41

- Improved TV Antenna From Naval Electronics page: 41

- Marathon LeTourneau Awarded Contract For Platform Rig Project page: 41

- Honda Will Use U.S.-Flag Central Gulf Lines Ship To Transport Cars To U.S. page: 41

- 9.7-Million Contract Awarded Bender For USS Pensacola Overhaul page: 41

- Motor Insulation System M e e t s N a v y Specifications page: 42

- MSC To Procure Additional Ships For Ready Reserve Force page: 42

- Phillips Reassigns Three In Supply, Transportation page: 43

- Radio H o l l a n d USA Announces N ew T h r a n e & Thrane Radiotelex Unit page: 43

- Nicor Installs Advanced Management System Aboard Supply Boat page: 43

- Grctndi Motori A l r e a d y Has Orders For Its N e w Long-Stroke M e d i u m - S p e e d Diesel page: 44

- National AirOil Introduces Portable Burner Ignitor page: 45

- Royal Caribbean Orders Three More Vessels page: 45

- M A R I N E LUBRICANTS MEETING T H E D E M A N D S OF N EW A N D U P G R A D E D DIESELS page: 46

- ANADAC Awarded Navy Support Services Contracts Totaling $4 Million page: 49

- N e w Rental Program For M a g n a v o x Equipment O f f e r s W i d e Selection page: 49

- Allison I m p l e m e n t s Performance, M a i n t e n a n c e , Reliability Improvements In M a r i n e Gas Turbines page: 50

- Free 12-Page Brochure On MARPAC Ball Valves From Mark Controls page: 51

- Integrated Ship Electronic Systems page: 52

- COMAR Offers Free Catalog On N e w Marine Products page: 53

- Powell Appointed Executive VP And General Manager, Bay Shipbuilding Corp page: 53

- Unaflex Introduces New Molded Expansion Joints page: 53

- Caterpillar Tractor Co. Renamed Caterpillar Inc. page: 53

- Russellstoll Offers Plugs, Receptacles And Connectors For Cord S e t s page: 54

- Action Threaded Products Offers 20-Page Color Brochure On Non-Corrosive Fasteners page: 54

- Valmet Automation Gets Order For Eight Damatic Systems From Yugoslavia page: 55

- Coastal States Trading Announces Personnel Changes page: 58

- Bailey Offers Custom Computer-Designed Refrigeration page: 58

- Gould Opens N e w Facilities For Circuit Breaker Repair, Overhaul page: 58

- MacGregor-Navire Access Gear Ordered For Vehicle Carriers Building In People's Republic page: 58

- Marine Travelift Hoists Now Feature Four-Wheel Drive page: 61

- Rockwell-Collins Awarded Contract To Supply Data Links For Spanish Navy page: 62

- American Ship Building To Enter Hawaiian Cruise Ship Trade page: 62

- First I n t e r n a t i o n a l Conference On Ice Technology Held At M IT page: 67

- Verolme To Build Two Corvettes For $50 Million For Brazilian Navy page: 67