Fourth Crandall Drydock For Belgium Placed In Service

The Port of Zeebrugge, Belgium, which is presently undergoing considerable expansion, recently inaugurated a new 1,200- ton Crandall r a i l w a y d r y d o c k, with a side transfer system to enable as many as four vessels to be docked simultaneously. The construction was undertaken by the Entreprises Maurice Delens of Brussels, using the general and detail design of Crandall Dry Dock Engineers, Inc. of Dedham, Mass.

This facility, the first of its kind in Zeebrugge, will permit the substantial fishing fleet of the area, as well as other harbor craft, to be drydocked in its home port rather than having to go to Ostend or Antwerp. It also will encourage a shipbuilding industry to develop in the Prinsfilip dock area where the drydock is located.

Sitting in a wet dock behind locks assures a constant water level within a range of 20 centimeters, permitting 24-hour docking.

The brackish water is too salty to freeze readily but not salty enough to support marine borer life.

The railway has foundation and underwater ways of azobe timber from Cameroon, and the inshore portion is of reinforced concrete.

A curved track causes the cradle to be rotated from its inclined attitude submerged to a horizontal position full up that permits easy side transfer.

A standard Crandall low-friction roller system is used for both hauling (with a single 2%-inch chain) and transfer. There is a cradle 72 meters long by 16 meters wide, with drafts over blocks of 3 meters inshore and 6 meters outshore. It has a capacity for concentrated loads of up to 35 tons per meter, with transfer limited to 24 tons per meter.

Because the outshore section can operate independently, there are forward latches to secure the bow cradle, and there is a wire rope bridle to keep the roller system in position.

A unique system for bilge block operation on the transfer cars is capable of reconnection so as to work directly on the main cradle.

This latest improvement, never used previously, has proved very successful and saves considerable time and labor in the transfer of vessels.

A vessel to be transferred sits on up to nine separate cars. It is propelled sideways by two independent hydraulic-powered drums, using 22-millimeter wire rope with 3-part tackle, a t t a c h e d at two points to the vessel itself. For security against wind forces, the transfer cars are provided with holding clamps on both the cradle and the transfer berths.

The project was financed by the national government of Belgium for the c i t y of Brugge through the Department of Public Works (Service de la Cote), and managed by Ir. Kerckaert, director, under the overall controll of Ir. Simoen, Inspector General.

Fabrication of structural steel was done by Victor Buyck of Eeklo; the hauling machine with all its electrical controls was manufactured by de Pecker of Gent, using certain elements supplied Crandall, while all civil works were carried out by Delens. Underwater work, particularly pile cutting and track i n s t a l l a t i o n, was s u b c o n t r a c t e d to Benelux Divers, Inc. of Antwerp.

Read Fourth Crandall Drydock For Belgium Placed In Service in Pdf, Flash or Html5 edition of May 1980 Maritime Reporter

Other stories from May 1980 issue

Content

- M a r A d W i l l Sponsor C o a l - F i r i n g Seminar page: 4

- Lobster Boat To Be D e s i g n e d By B l a n c ke page: 4

- Kormarine Will Have International Exhibits page: 4

- A m e r i c a n T r a d i n g Asks T i t l e X I For Six Tankers C o s t i n g $ 4 0 8 M i l l i on page: 6

- Halter Delivers Two Large-Capacity Crewboats page: 6

- T r a n s a m e r i c a D e l a v a l, Research-Cottrell Form Joint V e n t u re page: 6

- General Dynamics Christens Its First LNG Carrier Built For U.S. Trade page: 6

- Sembawang Yard To Invest In Construction Of New Floating Dock page: 8

- L i t e r a t u r e A v a i l a b l e On M a r i n e A n d O f f s h o re H y d r a u l i c Equipment page: 8

- S i f c o P r o v i d es O n b o a r d P l a t i n g - L i t e r a t u r e A v a i l a b le page: 8

- Australian Navy Heavy-Lift Ship Launched At Carrington Slipways page: 10

- D e l a w a r e V a l l e y ASNE Discusses Computer M o d e l i n g And Ship Performance page: 10

- Utility Vessel And Tugboat Delivered By Service Machine Group page: 10

- Promotions A nd Retirements At El Paso LNG Company page: 11

- Literature Available On New Decca Loran C Unit page: 11

- Guidance Notes For Coal-Burning Ships Available From Lloyd's page: 11

- Self-Unloading Bulk Carrier Delivered To ASC By Bay Shipbuilding page: 12

- Honeywell-ELAC Names Reimann As Consultant page: 12

- Hillman Changes Name To HBC Barge, Inc. page: 12

- George K. Geiger Joins Bay Shipbuilding Corp. page: 15

- Delaval Will Test Use Of Coal-Derived Fuel page: 15

- Navy Contracts Totaling $203 Million Awarded To Todd Shipyards- Backlog Is $1.5 Billion page: 16

- Halter Delivers Third 110-Foot Supply Vessel To C & E Boat Rental page: 17

- Amsterdam Dry Dock Announces Major Modernization Of Facilities page: 17

- First Of 60-Barge Order Delivered By NABRICO page: 17

- Garlock Introduces Expandable Packing- Literature Available page: 17

- Four Supply Vessels Of New Class Delivered To Tidewater Marine page: 18

- Fourth Crandall Drydock For Belgium Placed In Service page: 18

- Two Executives N a m ed At Mississippi M a r i ne page: 19

- Tacoma B o a t b u i l d i n g Appoints Two N e w M a r k e t i n g Directors page: 19

- N a i k a i Zosen Delivers The P r a n e d y a Pratama page: 19

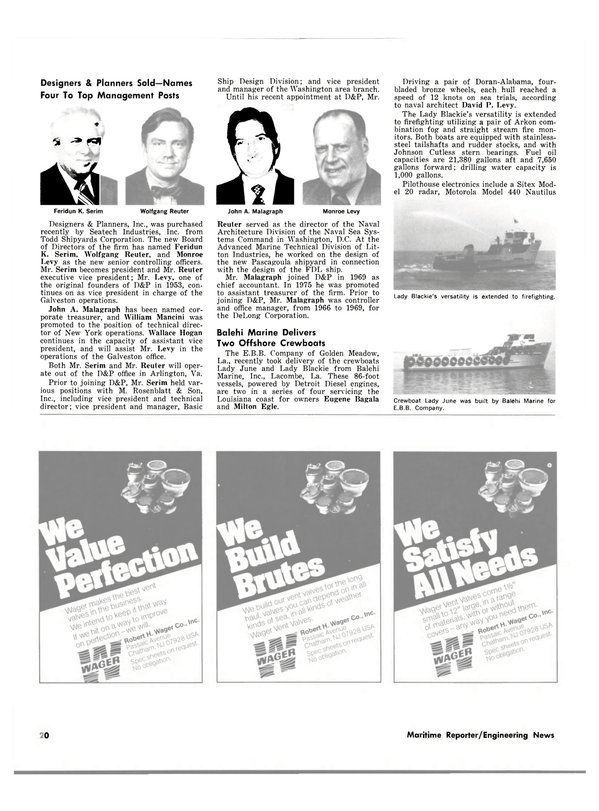

- Designers & Planners Sold—Names Four To Top M a n a g e m e n t Posts page: 20

- Balehi M a r i n e Delivers Two O f f s h o r e Crewboats page: 20

- Sarex Oil/Water Separators Approved By U.S. Coast Guard —Literature Available page: 20

- Paceco Cranes Delivered To Matson's L.A. Terminal page: 22

- AP L A n d Encinal To Develop Container Terminal In A l a m e da page: 23

- Norshipco To Complete O c e a n Barge For CCT page: 24

- The Shipbuilding Market In The USA page: 24

- Bulletin A v a i l a b l e On Elliott Tube Puller page: 26

- Bethlehem's Sparrows Point Y a r d Gets First Drilling Rig Contract page: 26

- McAllister Brothers Acquires Independent Towing Of Philadelphia page: 27

- N e w York Section SNAME Meeting Discusses Crude Oil Washing Systems page: 27

- L i t e r a t u r e A v a i l a b l e On B u t t e r w o r t h Systems N ew O i l / W a t e r Separators page: 28

- Hudship Reenters Pushboat M a r k et page: 28

- Literature Available On Bomar Deck Hatches page: 28

- Joint Venture Formed By Taylor And Hydrospace page: 28

- Record A t t e n d a n c e At I N A A n n u a l M e e t i ng page: 29

- Six A p p o i n t m e n ts Announced For I n t e r l a k e Steamship page: 29

- Literature Available From Elliott Co. On High-Speed Gears page: 29

- Santa Fe International And Acres Consulting Form Joint Venture page: 31

- New Rust Inhibitor Introduced By Farboil —Literature Available page: 31

- Paceco Awards Contract - P a r t Of $26-Million Expansion At Gulfport page: 31

- G u i d e d - M i s s i l e D D G Christened At Ingalls S h i p b u i l d i n g Y a rd page: 32

- Shaft A l i g n m e n t Was Topic At P h i l a d e l p h i a Section SNAME M e e t i ng page: 34

- Three A p p o i n t m e n t s Announced By R.J. Brown & Associates Firms page: 34

- Westinghouse Gets $ 6 - M i l l i o n Contract For Cruiser Gears page: 36

- W a r r e n T. M y e r s Joins W h i t e h a l l Brokerage page: 36

- Halifax Yard Awards $1.3-Million Contract For Modernization page: 36

- . J . Henry Elected To Norshipco Board page: 36

- Vincent Fiorenza Gets Added Duties At Moore McCormack page: 37

- M a g n a v o x O f f e r s N ew M o n i t o r i n g System — L i t e r a t u r e A v a i l a b le page: 38

- N e w Diesel Introduced By C u m m i n s E n g i n e - L i t e r a t u r e A v a i l a b le page: 38

- $C19.5-Million Modernization Under Way At Halifax Shipyards page: 38

- Student Paper Presented At SNAME Chesapeake Section page: 38

- T e n v i g Offshore A.S Develops Low-Cost Early Oil Production Ship page: 39

- $46.8-Million Research Facility To Be Built In St. John's, Newfoundland page: 40

- Blancke Gets Contract For Fishboat Design page: 41

- Tracor W i l l Develop Communications System For I n l a n d W a t e r w a ys page: 41

- New Salvage Technique Developed In Sweden page: 41

- $ 2 4 . 6 - M i l l i o n Contract A w a r d e d To Sperry For W o r k On Frigates page: 42

- L i t e r a t u r e A v a i l a b le On ITT Decca M a r i n e 's N e w A u t o p i l o t System page: 42

- M.A.N. Acquires Majority Shares in B & W Diesel A/S page: 42

- Literature Available On Chesterton Pump And Valve Packings page: 42

- Samson Offers Literature On Synthetic Ropes page: 43

- Literature Available On Tracor Automatic Omega page: 43

- NKK To Build Two Drill Rigs For Sedco At Cost Of $29 Million page: 43

- Safety And The Marine Environment page: 44

- R.A. Sleiertin Joins Career Associates page: 46

- Brochure Available On Comsat General Marisat Terminal page: 46

- N e w York City's Big A p p l e Goes To Sea page: 47

- Second Trident Submarine Launched At Electric Boat page: 47

- IME Meeting Discussed Combustion Systems And Use Of New Fuels page: 48

- Levingston And Asmar Deliver First Drill Rig Of A New Class page: 48

- New Oil/Water Emulsion System From Hoffert— Literature Available page: 49

- L P G / A m m o n i a Tanker D e l i v e r e d By W a r t s i la page: 50

- Literature Available On Simrad's Latest Digital Echosounders page: 50

- R.R. Barkerding Joins Ryan-Walsh Stevedoring page: 50

- SNAME New York Section Hears Paper On SWATH Vessels page: 51

- J.H. Leonhard Named Marketing Manager At International Paint page: 51

- Literature Available On Rockwell's Redesigned Steel Globe Valves page: 51

- Electric Boat Division Launches Navy Attack Submarine 'Boston' page: 55